Electrochemical polishing solution for zinc alloy devices and polishing method thereof

A zinc alloy, electrochemical technology, applied in the formulation of electrochemical polishing liquid and its polishing, and in the field of polishing of medical zinc alloy equipment, it can solve the problems of unstable polishing liquid composition, dullness, loss of polishing effect, etc., and achieve improved polishing Quality, reduction of replacement cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

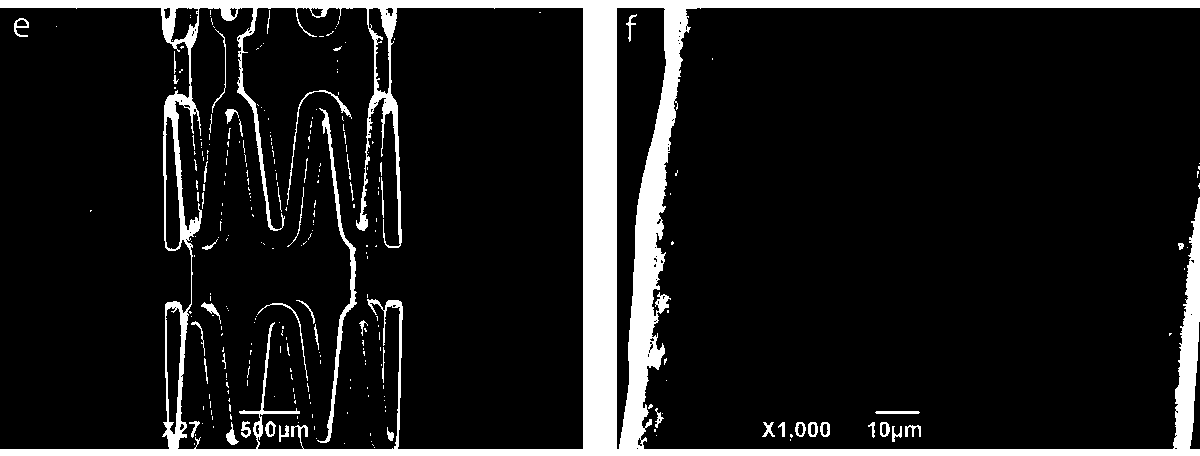

[0039] This embodiment uses this electrochemical polishing electrolyte and surface polishing technology to polish the surface of the Zn99Mg1 (atomic ratio) vascular stent so that it presents a specular luster. The specific steps are as follows:

[0040] Step 1: Clean the Zn99Mg1 vascular stent with a diameter of 2mm in sequence with acetone, purified water and absolute ethanol for 10 minutes respectively;

[0041] Step 2: Measure 150ml phosphoric acid, 700ml ethylene glycol dibutyl ether, and 150ml acetic acid in a fume hood, add phosphoric acid and acetic acid to ethylene glycol dibutyl ether in turn, stir for 10 minutes and mix to form a solution;

[0042] Step 3: Use the vascular stent as the anode and the lead plate as the cathode, and immerse it in the electrochemical polishing solution obtained in step 2. Turn on the power, take it out after electrolysis for 200s;

[0043] Step 4: After taking out the stent, immediately wash the surface with a large amount of flowing pu...

Embodiment 2

[0046] This embodiment uses this electrochemical polishing electrolyte and surface polishing technology to polish the surface of the Zn99Mg1 (atomic ratio) vascular stent so that it presents a specular luster. The specific steps are as follows:

[0047] Step 1: Clean the vascular stent with a diameter of 2mm in sequence with acetone, purified water and absolute ethanol for 10 minutes respectively;

[0048] Step 2: Measure 250ml of phosphoric acid, 500ml of ethylene glycol dibutyl ether, and 250ml of acetic acid in a fume hood, add phosphoric acid and acetic acid to ethylene glycol dibutyl ether in turn, stir for 10 minutes and mix to form a solution;

[0049] Step 3: The vascular stent is used as the anode, and the lead plate is used as the cathode, immersed in the electrochemical polishing solution obtained in step 2, the temperature is set to room temperature, and the distance between the cathode and anode is set to 15cm. Set the electrochemical polishing current to 0.5A, tu...

Embodiment 3

[0053] This embodiment uses this electrochemical polishing electrolyte and surface polishing technology to polish the surface of the Zn99Mg1 (atomic ratio) vascular stent so that it presents a specular luster. The specific steps are as follows:

[0054] Step 1: Clean the Zn99Mg1 vascular stent with a diameter of 2mm in sequence with acetone, purified water and absolute ethanol for 10 minutes respectively;

[0055] Step 2: Measure 350ml of phosphoric acid, 600ml of ethylene glycol dibutyl ether, and 50ml of acetic acid in a fume hood, add phosphoric acid and acetic acid to ethylene glycol dibutyl ether in turn, stir for 10 minutes and mix to form a solution;

[0056] Step 3: The vascular stent is used as the anode, and the lead plate is used as the cathode, immersed in the electrochemical polishing solution obtained in step 2, the temperature is room temperature, and the distance between the cathode and the anode is set to 15cm. Set the electrochemical polishing current to 0.5A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com