Lithium battery electrolyte as well as preparation method and application thereof

An electrolyte and lithium battery technology, applied in the field of electrochemistry, can solve problems such as high self-discharge rate, battery passivation, overgrowth, etc., and achieve high thermal stability, strong flame resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Raw material composition (parts by weight): 5 parts of lithium salt, 1 part of ethylene glycol dibutyl ether, 30 parts of methyl-nonafluorobutyl ether, 2 parts of high and low temperature resistant additives, and 10 parts of imidazole-based ionic liquid.

[0046] Lithium salt is LiBF 4 And bis(oxalate) lithium borate, the mass ratio is 1:1.

[0047] The high and low temperature resistant additives are dihydropyridine, azone and fluoroethylene carbonate, the mass ratio is 1:0.5:3.

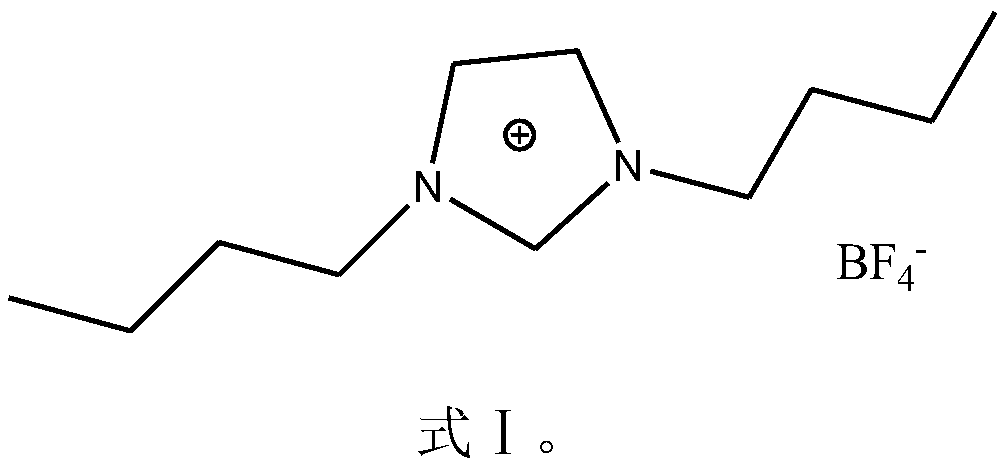

[0048] The structural formula of imidazolium-based ionic liquid is:

[0049] The preparation method of lithium battery electrolyte comprises the following steps:

[0050] S1. Use high-purity aluminum sheets for the positive and negative electrodes in an anhydrous environment, turn on the regulated power supply for electrolysis for 10 hours, and the voltage is 3V, and remove the water in the imidazolium-based ionic liquid and methyl-nonafluorobutyl ether;

[0051] S2. dissolving the lithi...

Embodiment 2

[0055] Raw material composition (parts by weight): 12 parts of lithium salt, 3 parts of ethylene glycol dibutyl ether, 50 parts of octafluoropentyl allyl ether, 5 parts of high and low temperature resistant additive, and 15 parts of imidazole-based ionic liquid.

[0056] Lithium salt is LiBF 4 And bis(oxalate)lithium borate, the mass ratio is 1:2.

[0057] The high and low temperature resistant additives are dihydropyridine, azone and fluoroethylene carbonate, and the mass ratio is 1:2:7.

[0058] The structural formula of imidazolium-based ionic liquid is:

[0059] The preparation method of lithium battery electrolyte comprises the following steps:

[0060] S1. Use high-purity aluminum sheets for the positive and negative electrodes in an anhydrous environment, turn on the regulated power supply and electrolyze for 15 hours at a voltage of 6V, and remove the water in the imidazolium-based ionic liquid and octafluoropentyl allyl ether;

[0061] S2. dissolving the lithium ...

Embodiment 3

[0065] Composition of raw materials (parts by weight): 6 parts of lithium salt, 2 parts of ethylene glycol dibutyl ether, 35 parts of sevoflurane, 3 parts of high and low temperature resistant additives, and 11 parts of imidazole-based ionic liquid.

[0066] Lithium salt is LiBF 4 And bis(oxalate)lithium borate, the mass ratio is 1:1.2.

[0067] The high and low temperature resistant additives are dihydropyridine, azone and fluoroethylene carbonate, the mass ratio is 1:0.7:4.

[0068] The structural formula of imidazolium-based ionic liquid is:

[0069] The preparation method of lithium battery electrolyte comprises the following steps:

[0070] S1. Use high-purity aluminum sheets for the positive and negative electrodes in an anhydrous environment, turn on the regulated power supply for electrolysis for 11 hours, and the voltage is 4V, and remove the water in the imidazolium-based ionic liquid and sevoflurane;

[0071] S2. dissolving the lithium salt in the imidazolium-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com