Patents

Literature

72 results about "Thiosulfate salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

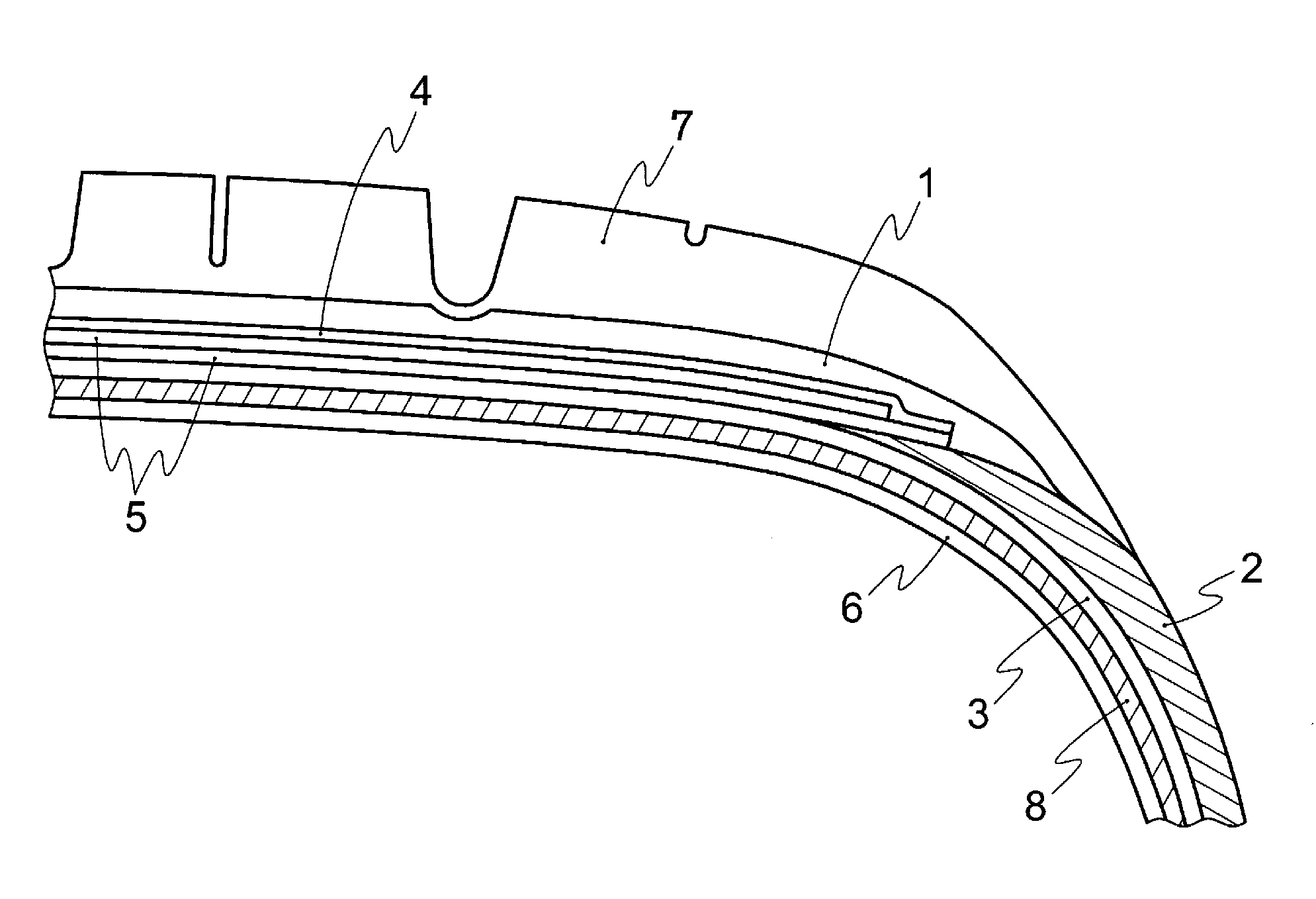

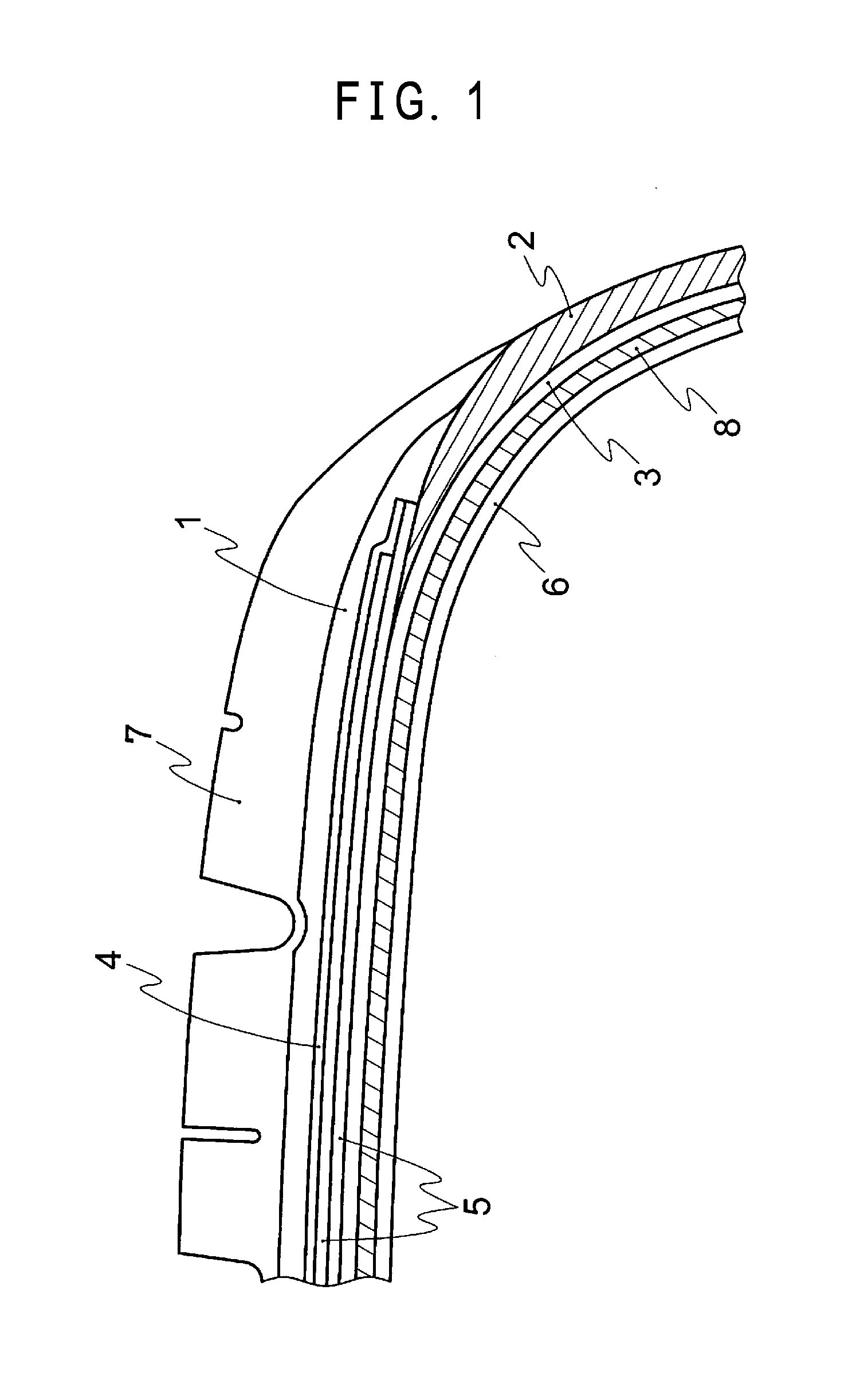

Tire with rubber tread of cap/base construction wherein the tread base rubber composition contains combination of anti-reversion agents

InactiveUS20030015271A1Improve propertiesAdvantageously producedSpecial tyresTyre tread bands/patternsBenzeneImide

The invention relates to a tire with rubber tread of cap / base construction. The tread base underlies the tread cap. The tread base is relatively thick, namely at least 50 percent of the thickness of the tread cap. It is desired that the tread base rubber composition contains a significant amount of sulfur to enhance physical properties of the tread base. The tread base rubber composition contains a combination of anti-reversion agents to counteract a tendency for reversion of physical properties of the tread base which is relatively thick as compared to the tread cap. The combination of anti-reversion co-agents is 1,3-bis-(citraconimidomethyl)benzene and hexamethylene 1,6-bis(thiosulfate), disodium salt, dehydrate thereby substantially maintaining the integrity of physical properties of the tread base, reduced tire operating temperature, as well as retarded or eliminated groove cracking in the tread cap has been observed.

Owner:THE GOODYEAR TIRE & RUBBER CO

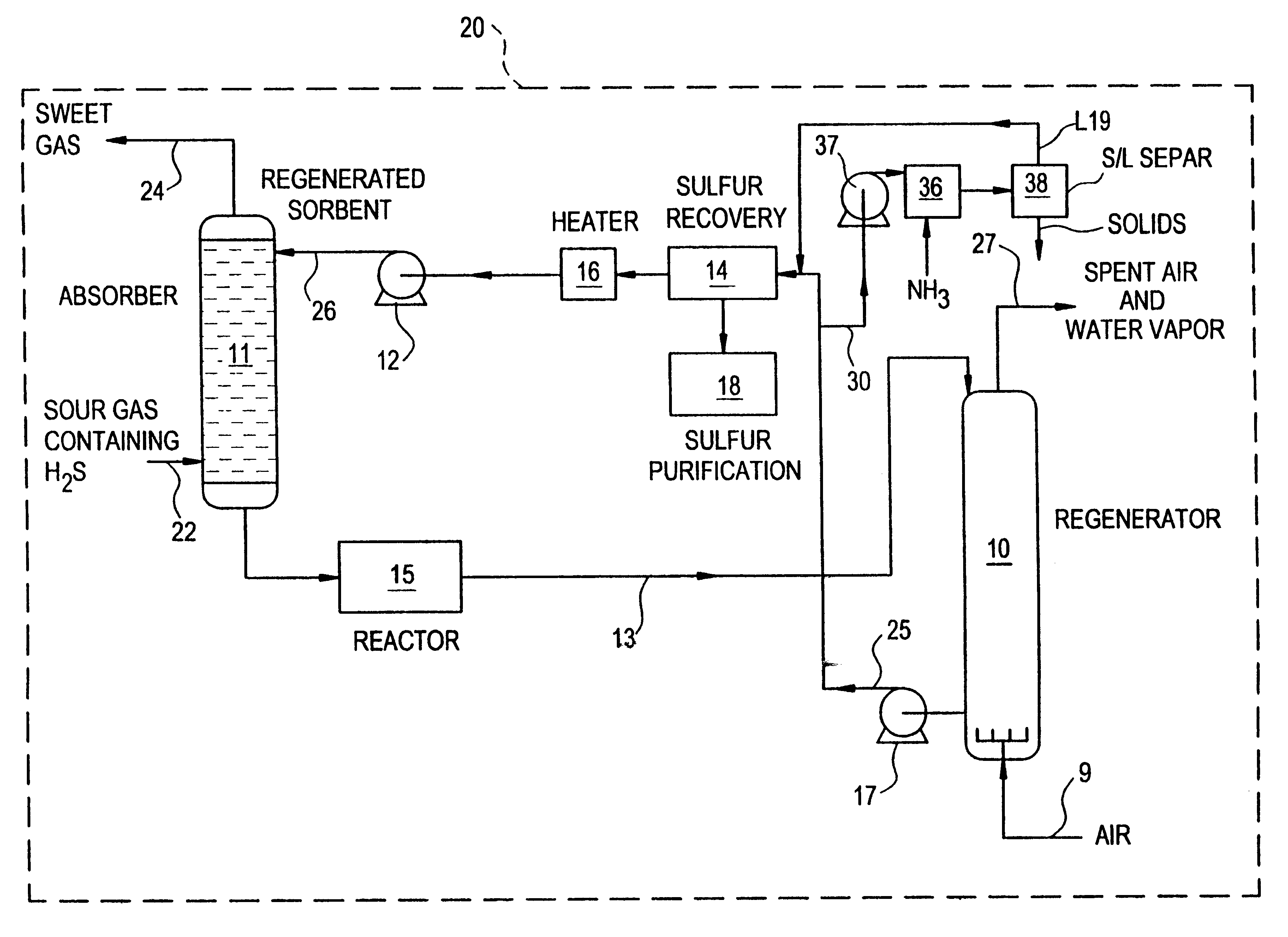

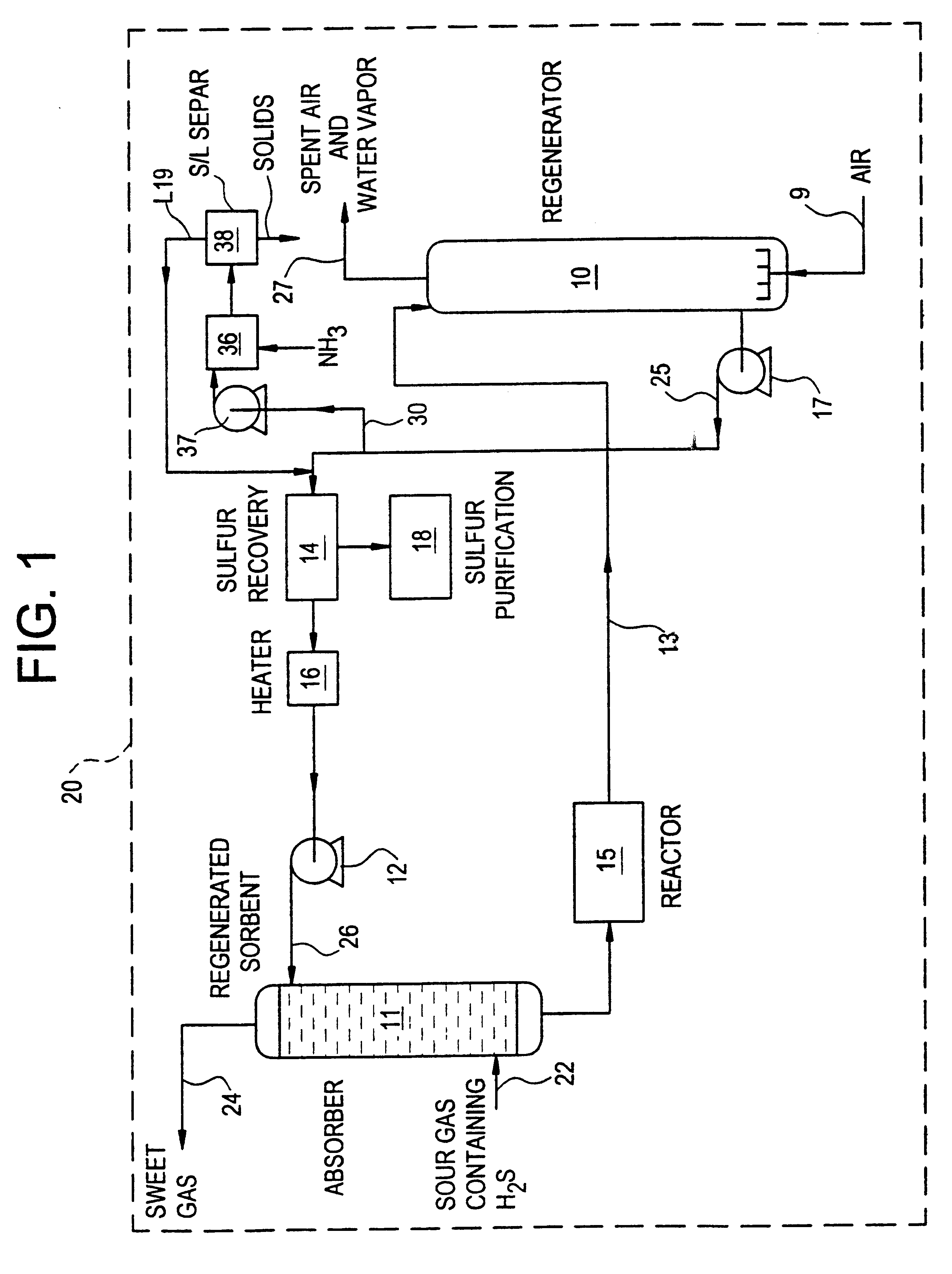

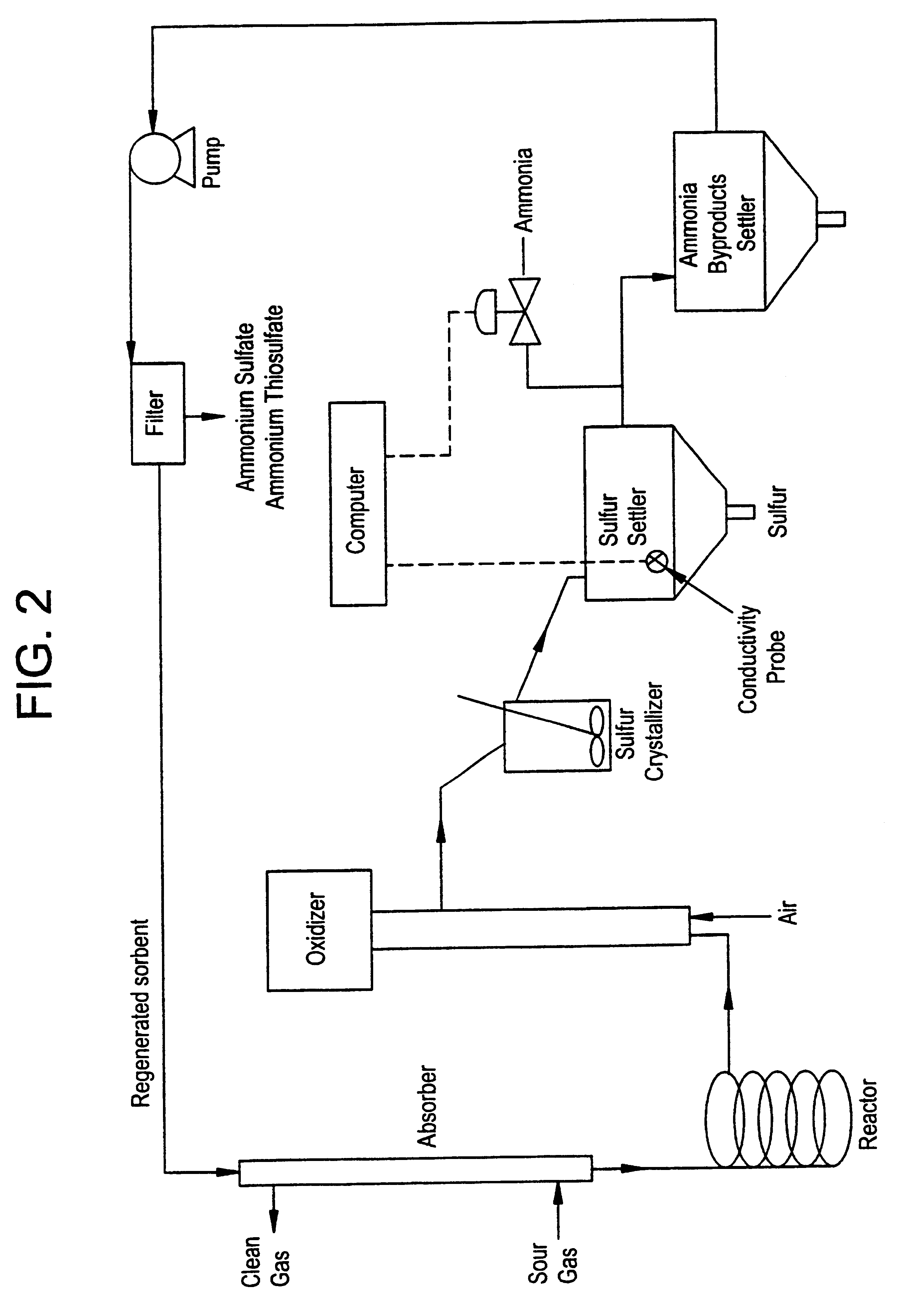

Regeneration method for process which removes hydrogen sulfide from gas streams

InactiveUS6544492B1Removal process is favorableAvoid problemsThiosulfates/dithionites/polythionitesHydrogen sulfidesThio-Sulfide

A process is provided for the removal of hydrogen sulfide out of a gaseous stream (22), such as a natural gas, by contacting the hydrogen sulfide containing gas with a sorbing liquid (26) containing a tertiary amine so that the hydrogen sulfide is sorbed into the liquid in absorber (11) and transferring the sorbing liquid / hydrogen sulfide mixture to a reactor (15) where the tertiary amine promotes the conversion of the hydrogen sulfide into polysulfide via reaction with sulfur; transferring the polysulfide solution from the reactor (15) to a regenerator (10) where polysulfide is converted into elemental sulfur via reaction with air (9); transferring at least a portion of the solution (25) containing elemental sulfur, as well as sulfate and thiosulfate species, into a mixture (36) where it is contacted with gaseous ammonia which reacts with the sulfate and thiosulfate species to produce ammonium sulfate and ammonium thiosulfate which are removed from the solution while the remaining portion of solution (25) is transferred to a sulfur recovery unit (14). That portion of the solution which has been subjected to ammonium sulfate and ammonium thiosulfate removal is rejoined with that portion of the solution (25) being forwarded to sulfur recovery unit (14). The solution from the sulfur recovery unit (14) is recycled back to the absorber (11).

Owner:URS

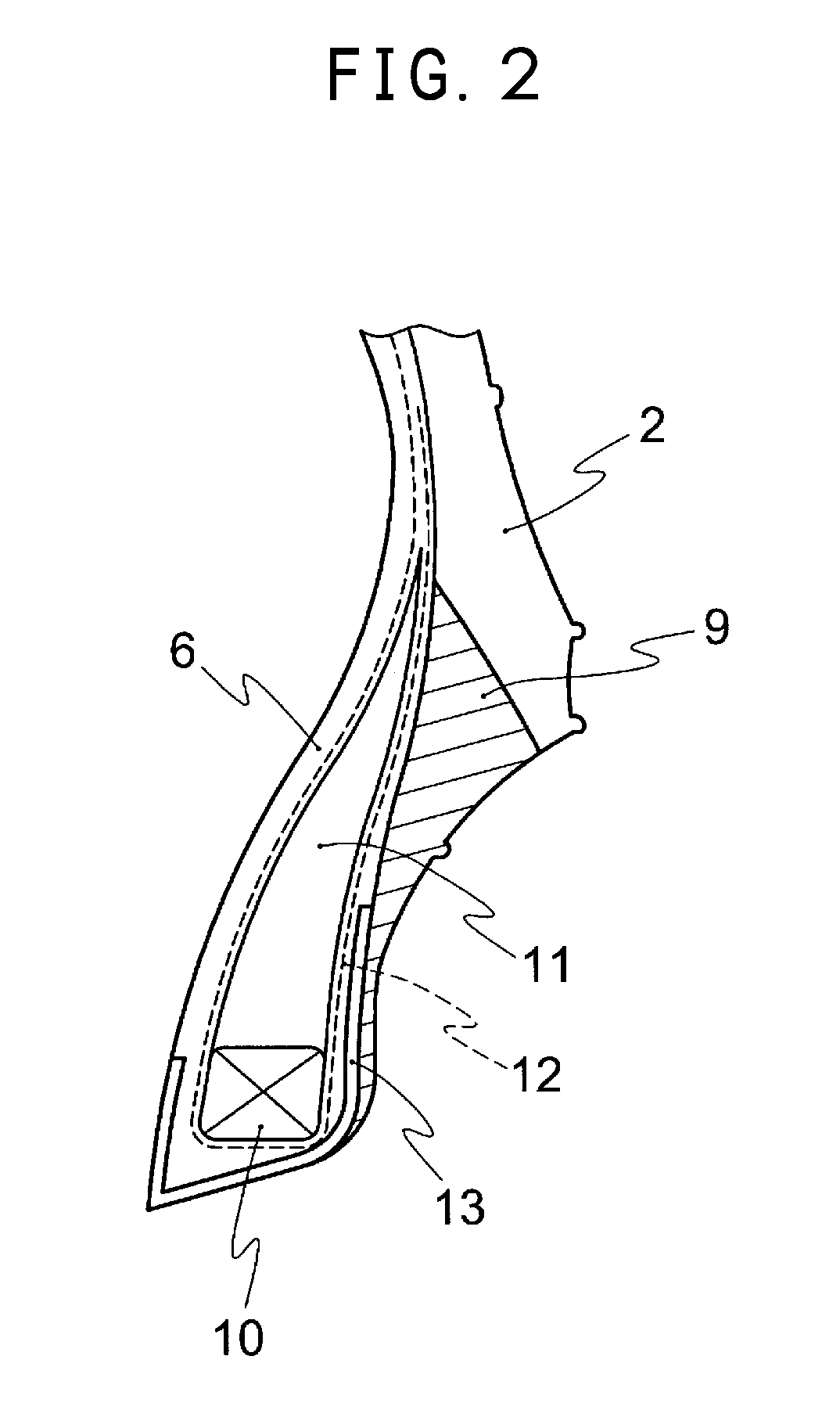

Rubber composition for tire

InactiveUS20100224299A1Good resistance stabilityImprove rolling resistanceSpecial tyresInflatable tyresVulcanizationPolymer science

The present invention relates to a rubber composition for a sidewall, a clinch and an insulation comprising 20 to 60 parts by mass of filler, 1.0 to 4.0 parts by mass of sulfur and 0.1 to 10 parts by mass of at least one vulcanization accelerating aid selected from a group comprising a citraconimide compound, an organic thiosulfate compound, an alkylphenol-sulfur chloride condensate, a compound represented by the formula (2) and a metal salt of methacrylic acid represented by the formula (3), based on 100 parts by mass of a diene rubber component comprising 10 to 70% by mass of at least one diene rubber component (a) selected from a group comprising a solution polymerization-modified styrene-butadiene rubber, a tin-modified butadiene rubber and a butadiene rubber whose terminal is modified with a compound represented by the formula (1), and 20 to 80% by mass of a diene rubber component (b) other than the diene rubber component (a) for the purpose of improving rolling resistance and steering stability.

Owner:SUMITOMO RUBBER IND LTD

Bentonite modifier, modified bentonite, and use thereof

ActiveUS20150144029A1Simple manufacturing methodImprove technical performanceSolid waste managementAlcoholWater soluble

The present disclosure relates to a bentonite modifier, comprising a water-soluble thiosulfate, a water-soluble alcohol compound, and a water-soluble amine compound, wherein the amounts of thiosulfate, the alcohol compound, and the amine compound are in the ratio of (0.3˜1):(0.3˜1):(0.3˜1). The present disclosure further relates to a bentonite-containing cement additive capable of resisting permeation and salt corrosion, comprising bentonite and said modifier, wherein the content of the bentonite modifier is 0.2˜5% of the bentonite by weight. Meanwhile, the present disclosure also provides use of the modified bentonite.

Owner:YIN WUJI

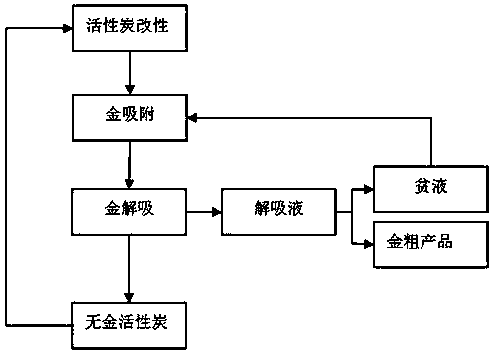

Preparation method and application of modified activated carbon for recovering gold

ActiveCN109589953ARich surface propertiesBroaden the field of applicationIon-exchange process apparatusOther chemical processesActivated carbonOrganic solvent

The invention discloses a preparation method and application of modified activated carbon for recovering gold and belongs to the fields of wet metallurgy and precious metal recovery. According to themethod, a modified activated carbon material is prepared under a certain condition by taking an activated carbon material as a matrix and thiourea as a modifier; and functional groups containing atomssuch as nitrogen, oxygen and sulfur are introduced to the surface of activated carbon, so that the properties on the surface of the material are changed, and [Au(S2O3)2]3-complex ions in a thiosulfate gold immersion solution are effectively adsorbed. By using the method disclosed by the invention, the defects that existing Prussian blue-like compound modified activated carbon is complex in preparation process and unstable in product structural performances and expensive modifiers and organic solvents are used by 2-mercaptophenylthiazole modified activated carbon are overcome; and the preparation method has the advantages such as simple preparation method, low price and environment friendliness.

Owner:KUNMING UNIV OF SCI & TECH

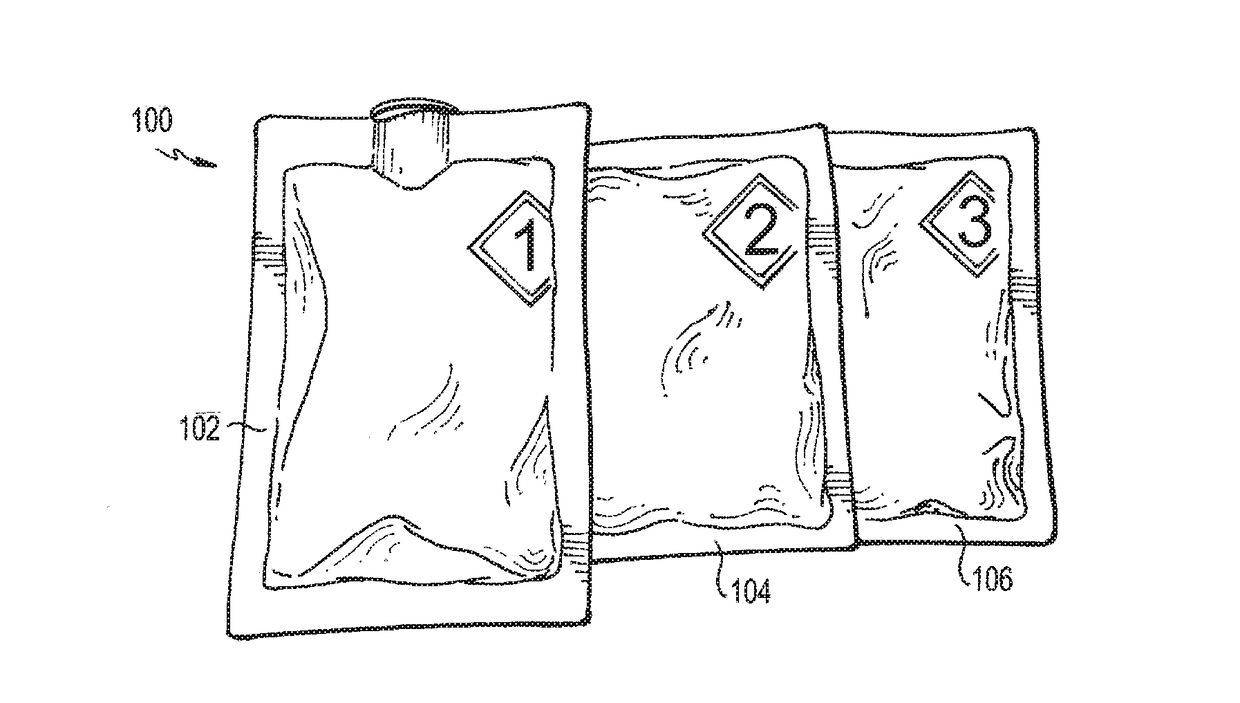

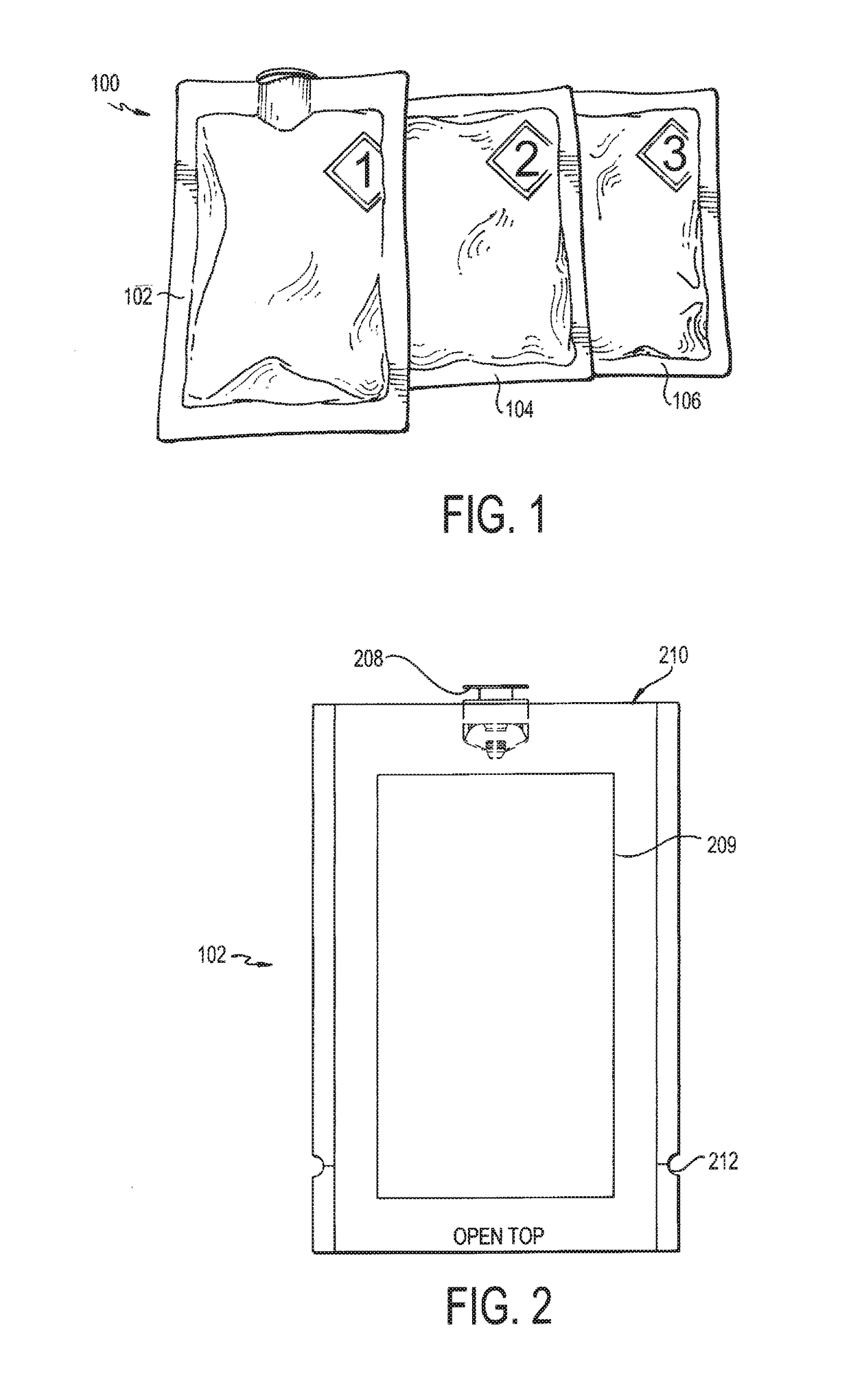

Deactivation wipe kit and method of forming and using the same

A hazardous drug deactivation wipe kit includes a first pouch having a one-way valve coupled to an end thereof, a second pouch, and a third pouch. The first pouch contains a wipe saturated in a hypochlorite solution, the second pouch contains a wipe saturated in thiosulfate solution, and the third pouch contains a wipe saturated in isopropyl alcohol solution. The deactivation wipe kit may be used in a clean room to deactivate most hazardous drugs on a work surface.

Owner:VALTEK ASSOC INC

Thiosulfate gold leaching method using cobalt and ethylene diamine tetraacetic acid (EDTA) as catalysts

ActiveCN105603185AReduce consumptionPrevent oxidationProcess efficiency improvementSal ammoniacEthylene diamine

The invention discloses a thiosulfate gold leaching method using cobalt and ethylene diamine tetraacetic acid (EDTA) as catalysts. The thiosulfate gold leaching method is characterized in that the cobalt and EDTA are used to replace traditional copper and ammonia for catalyzing, that is to say, cobalt sulfate and EDTA instead of copper sulfate and ammonia water are added into ore pulp. A thiosulfate method which is nontoxic and cheap in leaching agent, fast in gold leaching, low in equipment corrosion due to the fact that gold leaching is performed in an alkaline medium, and the like is widely believed to be the most promising non-cyanidation gold leaching method, but the thiosulfate method has the problems of large leaching agent consumption caused by the fact that Cu(NH3)4<2+> oxidizes S2O3<2-> and environment threatening caused by ammonia use. The thiosulfate gold leaching method has the advantages that the method can evidently reduce the consumption of thiosulfate, avoid ammonia water's threat to environments, and the gold leaching rate of the method is equivalent to that of a traditional method using copper and ammonia as catalysts.

Owner:CENT SOUTH UNIV

Preparation method and application of ammonium thiocyanate modified activated carbon

ActiveCN109574008ARich surface propertiesBroaden the field of applicationCarbon compoundsOther chemical processesSkin complexionActivated carbon

The invention discloses a preparation method and an application of ammonium thiocyanate modified activated carbon, and belongs to the field of wet metallurgy and precious metal recycling. According tothe method, an activated carbon material serves as a substrate, ammonium thiocyanate serves as a modified agent, and a modified activated carbon material is prepared under a certain condition. Functional groups containing atoms such as nitrogen, oxygen and sulfur are introduced on the surface of the activated carbon, so that surface properties of the material are changed, and [Au(S203)2]3-complexions in thiosulfate gold leaching solution are effectively adsorbed. The method overcomes the shortcomings that a current Prussian blue analogue compound modified activated carbon preparation processis complicated and unstable in product structure performance, 2-mercaptobenzothiazole modified activated carbon adopts expensive modified agents, toxic organic solvents and the like, and the method has the advantages of simple preparation method, low cost, environmental friendliness and the like.

Owner:KUNMING UNIV OF SCI & TECH

Thiosulfate gold extraction method taking alkyl trimethyl quaternary ammonium salt as additive

InactiveCN103740930AReduce consumptionImprove leaching rateProcess efficiency improvementThio-Hydrometallurgy

The invention discloses a thiosulfate gold extraction method taking an alkyl trimethyl quaternary ammonium salt as an additive and belongs to the technical field of wet metallurgy. Aiming at the problems of a traditional thiosulfate leaching method adopted by some ores that the leaching efficiency is low and the consumption of reagents is great, ore pulp is modified and then is treated; after the ore pulp is modified by using the thiosulfate gold extraction method, thiosulfate, ethidene diamine and a copper ion gold leaching solution are used for leaching and the leaching rate is higher than 75%; the process is simple to operate and easy to control; the consumption amount of the thiosulfate is very low; components of the gold leaching solution are simple and gold in the gold leaching solution is easy to recycle; the applicable range is wide and the leaching effect is good under the condition that the pH (Potential of Hydrogen) is 9-12; the leaching speed of gold ores which are highly slimed by limonite is rapid and the relatively-high gold leaching rate can be kept; toxic substances including sodium cyanide and the like are not utilized in a gold extraction process and toxic wastes are not discharged; the thiosulfate gold extraction method is environment-friendly.

Owner:KUNMING UNIV OF SCI & TECH

Safe sole material and preparation method thereof

The invention provides a safe sole material and a preparation method thereof. The safe sole material comprises, by weight, 100 parts of TPE, 150 parts of PS, 111 parts of PE, 70 parts of rice bran, 22 parts of dibutyl ether, 36 parts of ethyl acetate, 27 parts of thiosulfate, 18 parts of olive oil, 19 parts of acetone and 10 parts of aniline. The preparation method for the safe sole material comprises the following steps: mixing above-mentioned components in proportion and placing obtained mixture in an internal mixer for banburying; granulating the mixture after banburying with a granulator so as to obtain particles; cooling the particles in a water tank and drying the particles at room temperature. Soles prepared from the safe sole material provided in the invention are antistatic and oil resistant, have a good heat insulating and cold-proof effect, and are applicable to a variety of work environments.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

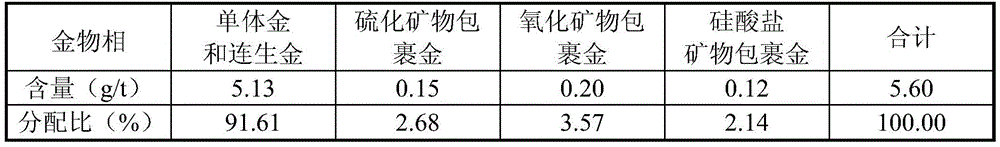

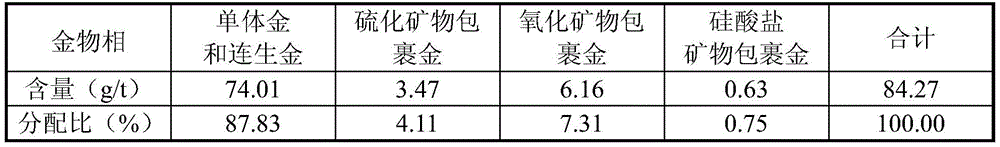

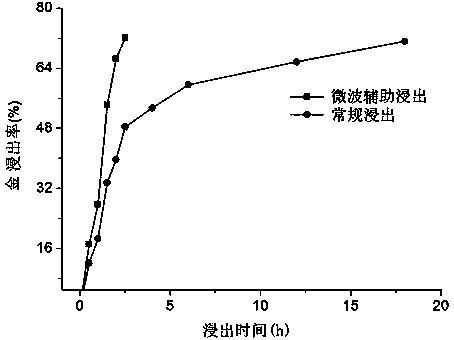

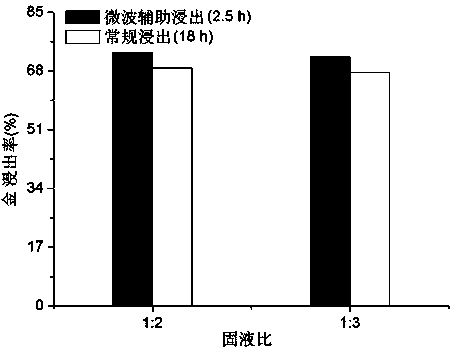

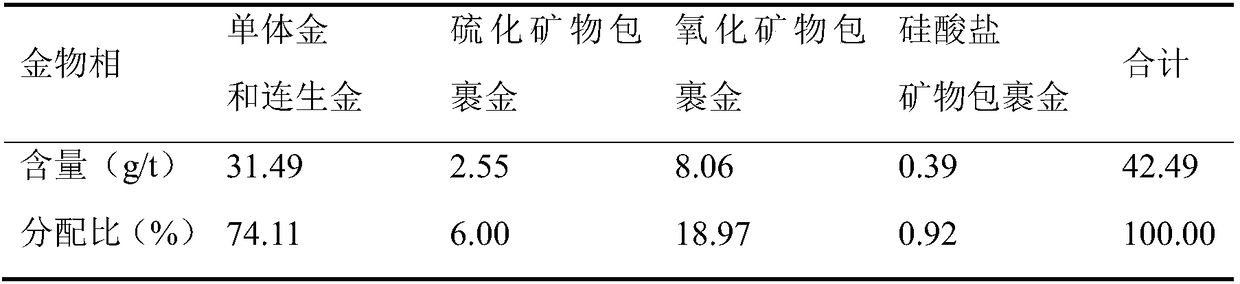

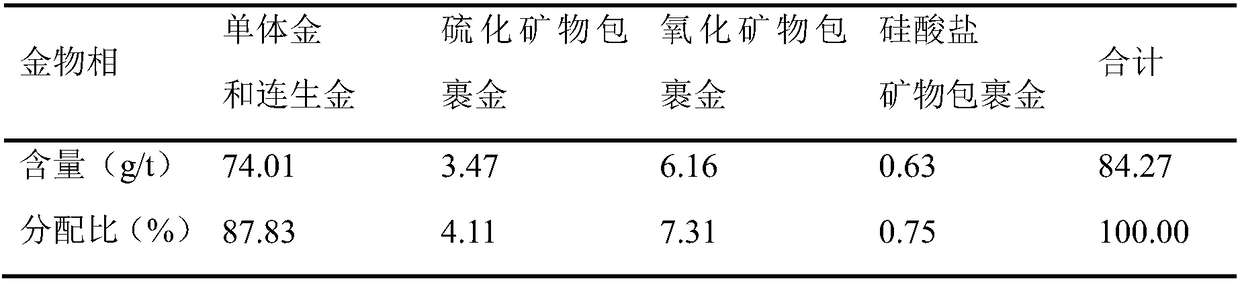

Oxidizing roasting-microwave-assisted leaching gold extraction method for high-arsenic gold-bearing sulfur concentrate

ActiveCN104313343AReduce pollutionImprove gold leaching rateProcess efficiency improvementLiquid ratioSlag

The invention relates to an oxidizing roasting-microwave-assisted leaching gold extraction method for high-arsenic gold-bearing sulfur concentrate. The specific implementation method is as follows: 1, oxidizing roasting, spreading high-arsenic gold-bearing sulfur concentrate in a quartz boat, placing the quartz boat in a resistance furnace, taking out the quartz boat after roasting for 2h, and weighing until ore is cooled; 2, microwave-assisted leaching, preparing specially-made thiosulfate solution which serves as leaching agent, and placing the roasted high-arsenic gold-bearing sulfur concentrate and the prepared thiosulfate solution in a microwave device for microwave-assisted leaching according to the solid-to-liquid ratio of 1:(2 to 3); 3, calculating slag-based leaching rate. Compared with the conventional method of directly leaching after roasting, the method provided by the invention has the advantage that after roasting, microwave is adopted to help thiosulfate to leach, so that the leaching period is short, the leaching rate is high, and the environmental pollution is low; the invention is applicable to leaching of other high-sulfur and high-arsenic gold ore which is difficult to treat.

Owner:NANHUA UNIV

Gold leaching method adopting ferrous ions and magnesium thiosulfate

InactiveCN108546827AReduce consumptionEliminate competitive adsorptionProcess efficiency improvementDesorptionDecomposition

The invention discloses a gold leaching method adopting ferrous ions and magnesium thiosulfate. The gold leaching method is characterized in that a ferrous ion solution and a magnesium thiosulfate solution is added into gold-containing minerals so as to leach out gold in the gold-containing minerals. According to the gold leaching method, oxidative decomposition of Cu(NH3)4<2+> to S2O3<2-> is eliminated, so that the consumption of thiosulfate is greatly reduced; Cu(S2O3)2<3-> / Cu(S2O3)3<5-> is prevented from disturbing gold adsorption by resin, the competitive adsorption of Cu(S2O3)2<3-> / Cu(S2O3)3<5-> to the gold on the surface of the resin is weakened, the recovery of the gold in a leachate adopting the resin adsorption method is facilitated, and the desorption of the gold-bearing resin can be realized by adopting a simple one-section process; and the addition of ammonia water is avoided, and therefore the threat of NH3 to the atmosphere and the environment of the water body is eliminated. The gold leaching rate of the gold leaching method is equivalent to that of a traditional gold leaching method adopting copper ions, ammonia or thiosulfate, but the gold leaching method solves the problem that in the traditional gold leaching method adopting thiosulfate is high in thiosulfate consumption and unfriendly to the environment, and the recovery of gold from the leachate is difficult.

Owner:CENT SOUTH UNIV

Iron control agent

ActiveUS8003581B1Minimize and eliminate sludge formationInhibition formationCleaning apparatusFluid removalSulfite saltTin(II) chloride

An iron control agent capable of reducing ferric iron containing compounds to ferrous iron containing compounds in an acidic solution, such as one used for formation acidizing. The iron control agent comprises a combination of a sulfur dioxide, sulfurous acid, sulfite salts, bisulfite salts, or thiosulfate salts or mixtures thereof, with a source of copper ions and a source of iodine or iodine ions. The iron control agent may also include small amounts of an adjunct such as stannous chloride, 2-mercaptoethanol, and thioglycolic acid and its salts.

Owner:ENERGY SOLUTIONS (US) LLC

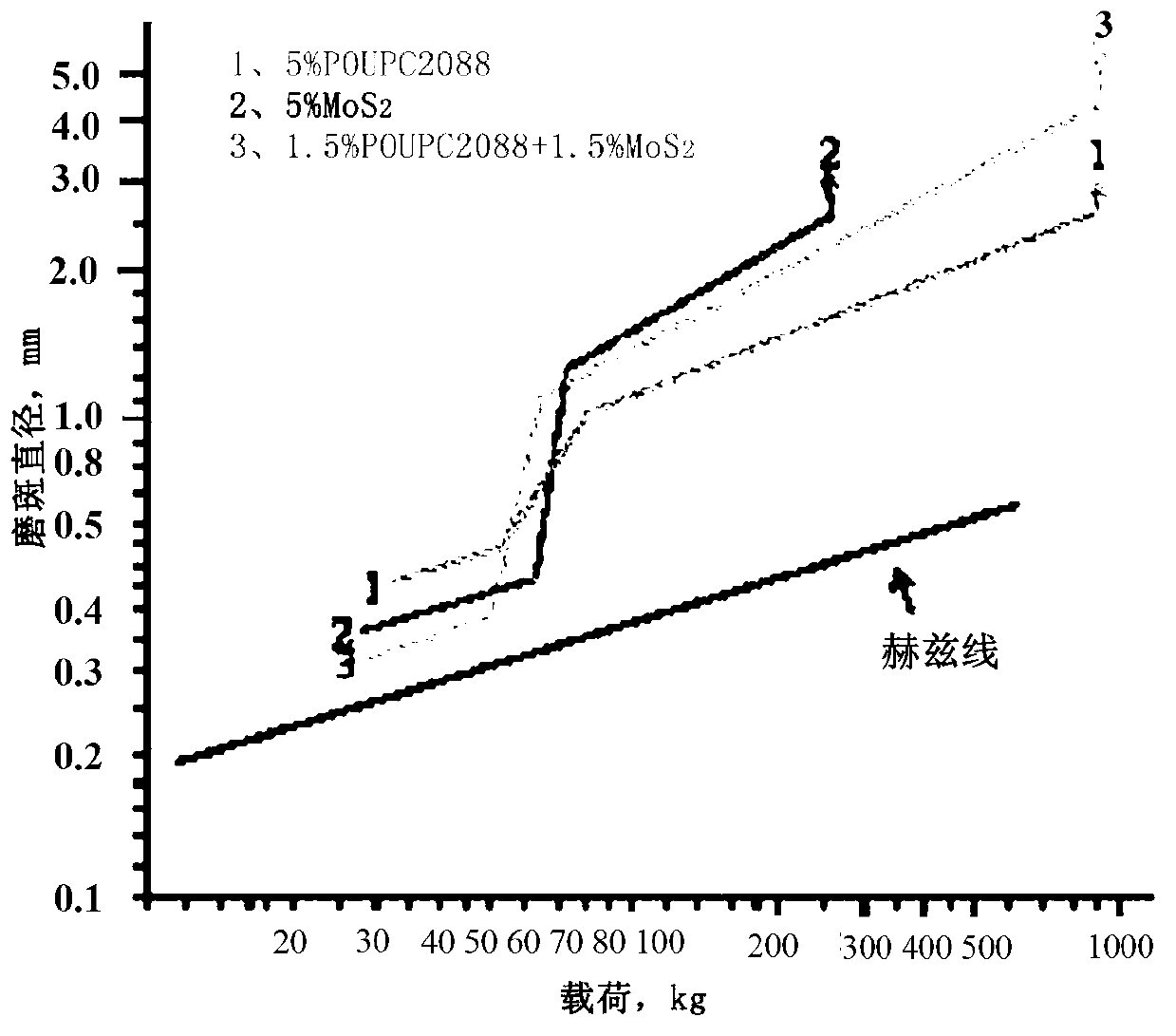

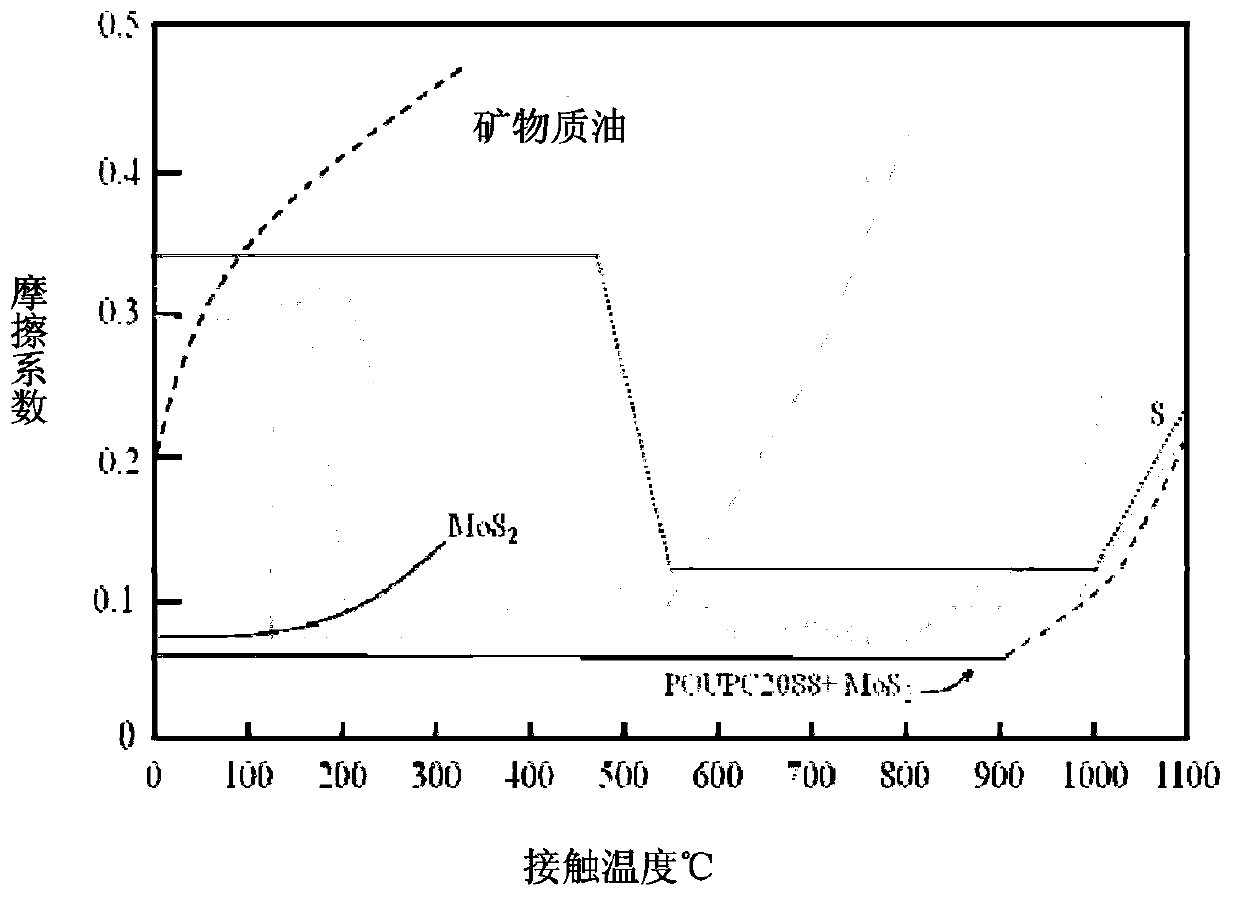

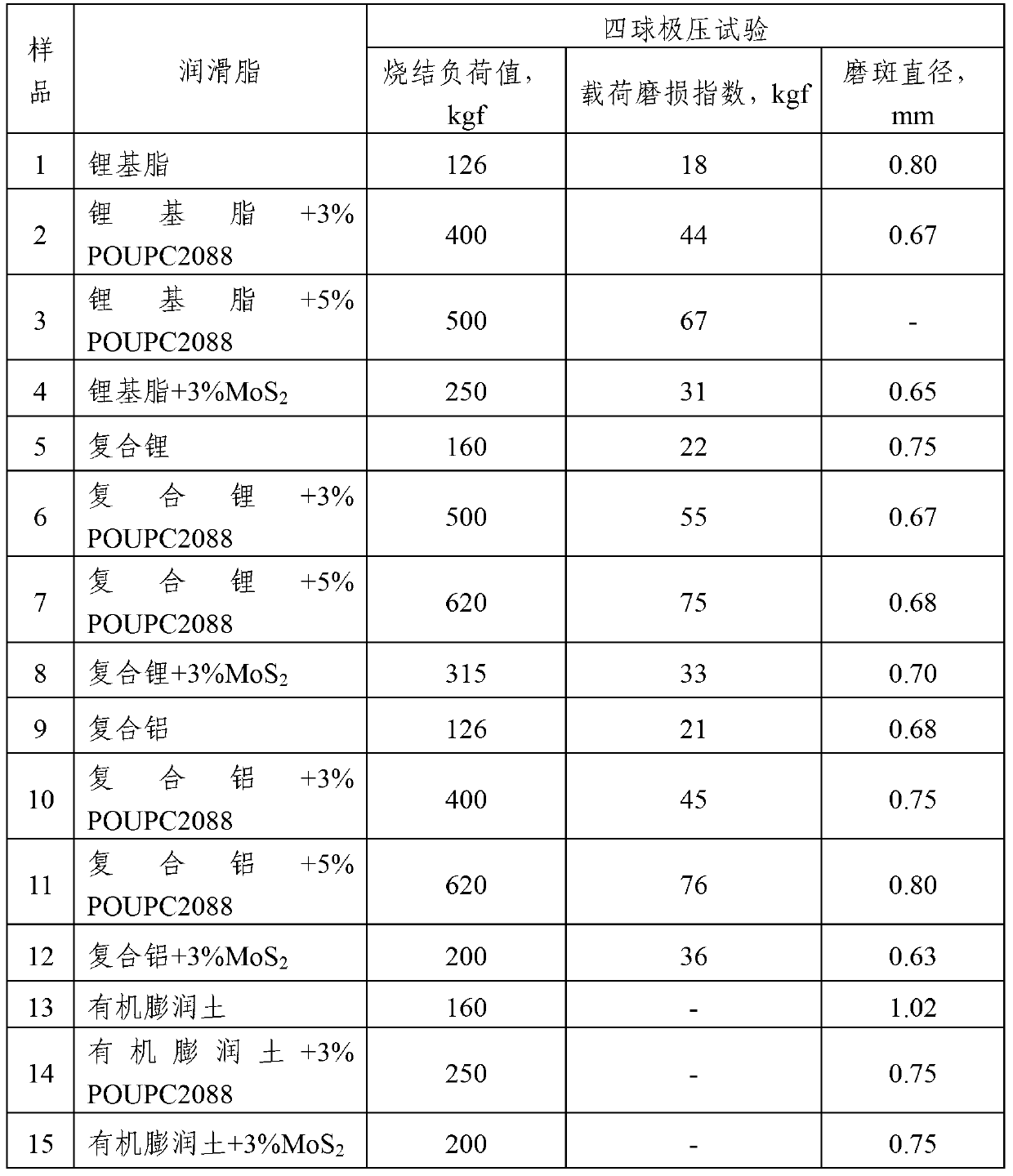

Sulfur and phosphorous-containing extreme pressure anti-wear reagent and preparation method and application thereof

ActiveCN103275787AGood extreme pressure and anti-wear propertiesGood additionAdditivesPhosphateMechanical equipment

The invention provides a sulfur and phosphorous-containing extreme pressure anti-wear reagent and a preparation method and application thereof. The product is an organic mixture of thiosulfate and phosphate. The product serving as a lubricating additive is applied to lubricating oil and has the functions of obviously improving the anti-wear extreme pressure performance and effectively protecting the mechanical equipment. The product is light in color, odourless and non-toxic, does not have adverse effect on the environment and is a high-performance environment-friendly lubricating oil extreme pressure anti-wear reagent.

Owner:太平洋联合(北京)石油化工有限公司

Method for recovering gold from gold-loaded carbon in thiosulfate system

The invention discloses a method for recovering gold from gold-loaded carbon in a thiosulfate system, and belongs to the field of wet metallurgy and precious metal recovery. The method comprises the steps that the gold-loaded carbon is washed with ionized water to remove ash, and is then filtered and heated to be activated; and then, the heated gold-loaded carbon is placed in a thiosulfate solution for desorption. The method has the advantages that the cost is low and a desorption reagent is safe and non-toxic; gold on the gold-loaded carbon can be effectively desorbed without destroying active carbon; and the purpose of cyclic utilization of active carbon can be achieved through re-modification of activated carbon.

Owner:KUNMING UNIV OF SCI & TECH

Sulfide or thiosulfate catalytic air complete oxidation at normal temperature and pressure

ActiveCN101798068AEasy to separateThere is no problem of secondary pollutionSulfate preparationPtru catalystThio-

The invention relates to a catalysis and oxidation treatment method for wastewater containing sulfide or thiosulfate, which is used for completely oxidizing sulfide and / or thiosulfate into sulfate at normal temperature and pressure by using gas as an oxidant and using a compound containing trivalent bismuth as a catalyst. The catalyst used in the invention can be recycled, which not only solves the problem that sulfide and / or thiosulfate can not be oxidized into stable sulfate by using a traditional catalytic air oxidation method, but also is beneficial to environmental protection, decreasing the investment, saving the operation cost, and realizing simple operation. Therefore, the invention can be widely applied to treatment on wastewater containing sulfide and / or thiosulfate or alkali waste liquid.

Owner:西安德兴环保科技有限公司

Preparation method of oil-resistant antiskid rain boot sole material

The invention provides a preparation method of an oil-resistant antiskid rain boot sole material. The oil-resistant antiskid rain boot sole material comprises a component A and a component B in a mass ratio of (2-4):1. The component A is prepared from the following ingredients in parts by weight: 80-100 parts of natural rubber, 30-40 parts of TPE (thermoplastic elastomer), 10-20 parts of butadiene-acrylonitrile rubber, 80-94 parts of ethylene propylene diene monomer, 66-72 parts of hydroxylated polypropylene, 16-22 parts of polyolefin elastomer, 15-19 parts of glass fiber, 4-6 parts of bridging agent, 1-3 parts of bridging aid and 10-16 parts of pentane. The component is prepared from the following ingredients in parts by weight: 22-33 parts of white carbon black, 23-26 parts of calcium zinc salt, 9-15 parts of tribasic lead sulfate, 11-17 parts of plasticizer DOP, 25-36 parts of rice bran, 3-10 parts of thiosulfate, 7-11 parts of stearic acid, 9-14 parts of vaseline, 11-13 parts of dioctyl adipate, 3-5 parts of anti-aging agent, 1-3 parts of activator, 1-4 parts of filler, 2-3 parts of activator and 1-4 parts of foaming agent. The shoe sole material has the advantages of simple preparation technique, low cost, favorable air permeability, favorable elasticity, light weight, favorable flexibility, oil resistance and skid resistance.

Owner:NANJING DONGYA RUBBER & PLASTICS

Method for directly recovering gold in thiosulfate system by using activated carbon

The invention discloses a method for directly recovering gold in a thiosulfate system by using activated carbon, and belongs to the technical fields of hydrometallurgy and precious metal recovery. According to the method, an organic matter containing a thiocyanogen (-S-C(triple bond)N) group or an isothiocyanogen (N=C=S) group is used as an additive of a thiosulfate system gold leaching solution,the environment of the solution can be changed by using the additive, and finally Au(S2O3)23- in the solution can be directly adsorbed and recovered by using unmodified activated carbon. According tothe method, the problems of environmental pollution, equipment corrosion and the like caused by modified activated carbon are effectively avoided, and the method is suitable for application in actualproduction; the operation process is simple and easy to control, the reagent dosage is low, and the cost investment is reasonable; and the gold can be efficiently recovered by the unmodified activatedcarbon in a short time under the condition of low additive dosage, and the progress of the thiosulfate gold extraction technology towards industrial development can be accelerated.

Owner:KUNMING UNIV OF SCI & TECH

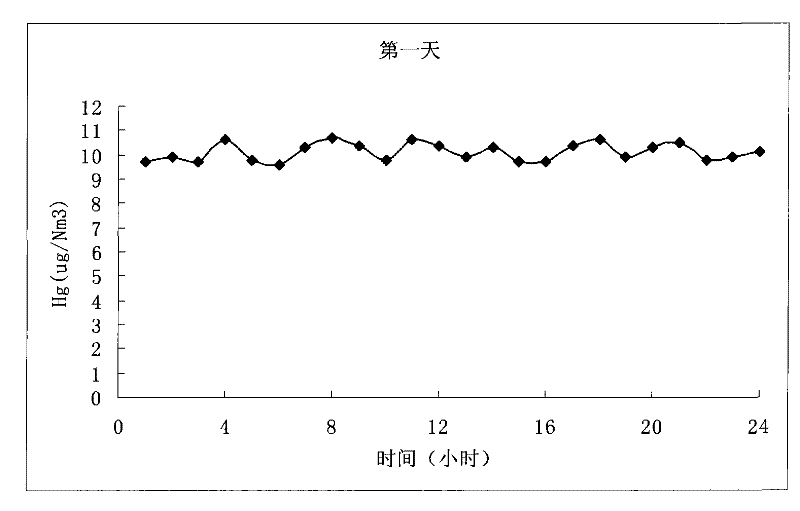

Desulfurization and denitration carbon base fuel fume mercury absorbent and use thereof

InactiveCN101417223BEnhanced shape transformation abilityImprove adsorption capacityOther chemical processesDispersed particle separationModified carbonElemental mercury

The invention discloses a carbon-based coal-fired fume mercury adsorbent and an application method thereof which can carry out the desulfurization operation and the denitration operation simultaneously. The method mixes haloid salt and thiosulfate to prepare a solution which is used as chemical modifier so as to dip the active carbon, thus obtaining the modified carbon-based coal-fired fume mercury adsorbent. The adsorbent has the applications of mercury removal, desulfurization and denitration in boilers of coal-fired power plants simultaneously; the adsorbent is sprayed into the fume of the boiler of the coal-fired power plants at the temperature of 110-350 DEG C so as to mix with the fume; the stoichiometric ratio of the adsorbent sprayed into the fume and heavy metal mercury in the fume is 1-5:10<4>; and the proportion of the adsorbent and the fly ash in the fume is 1-5:10<4>. The adsorbent can oxidate the elemental mercury in the fume as divalent mercury, realizes the comprehensive control on the mercury and CO2 in the fume, generates no side effects on the use of the fly ash of the coal-fired power plant, and generates no secondary pollution.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

Water loss reducing agent used for well cementation in deepwater at low temperature and preparation method thereof

ActiveCN103087693AIncrease concentrationSave storage spaceDrilling compositionPolyvinyl alcoholDual action

The invention relates to a water loss reducing agent used for well cementation in deepwater at a low temperature. The water loss reducing agent is a water suspension comprising polyvinyl alcohol and thiosulfate. The water loss reducing agent provided by the invention has dual functions of reducing water loss and coagulating at a low temperature, an effect of 'one agent with dual purposes' is realized, and field service is simplified; meanwhile, the water loss reducing agent can be directly added into well cementation mixed water to be used instead of being dryly mixed with cement, and effective concentration of a water loss reducing component is high, so that a limited material storage space of an offshore platform can be effectively saved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

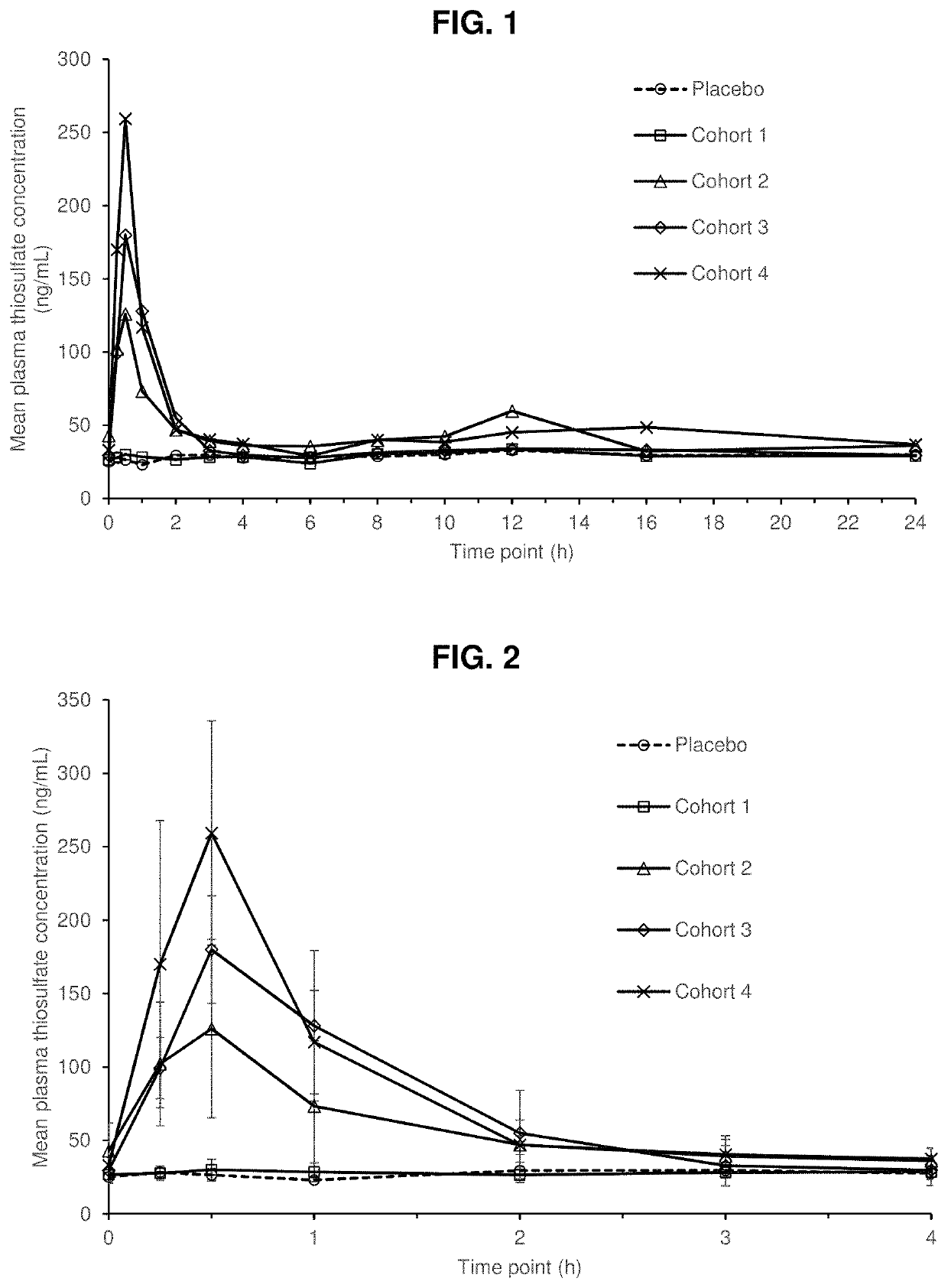

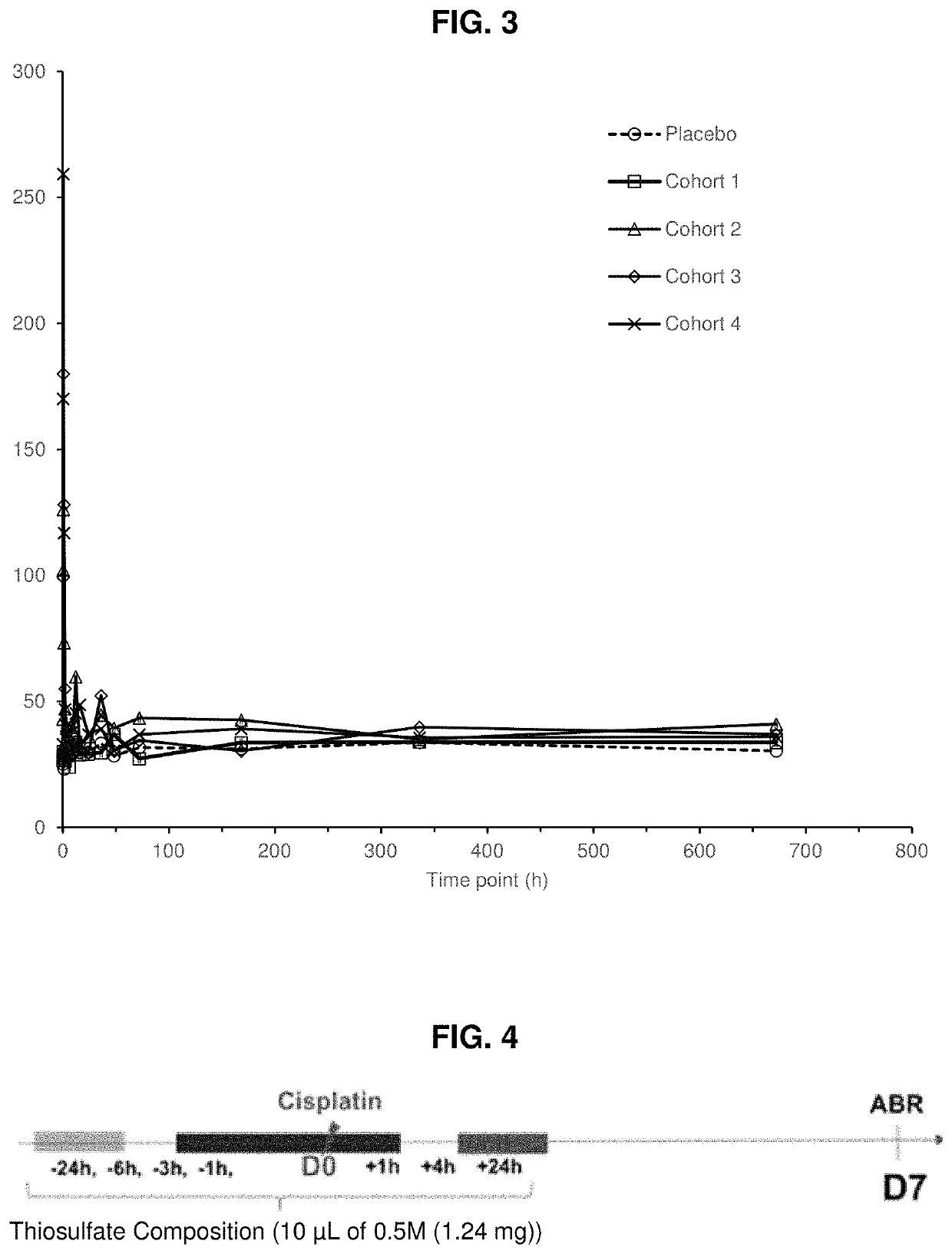

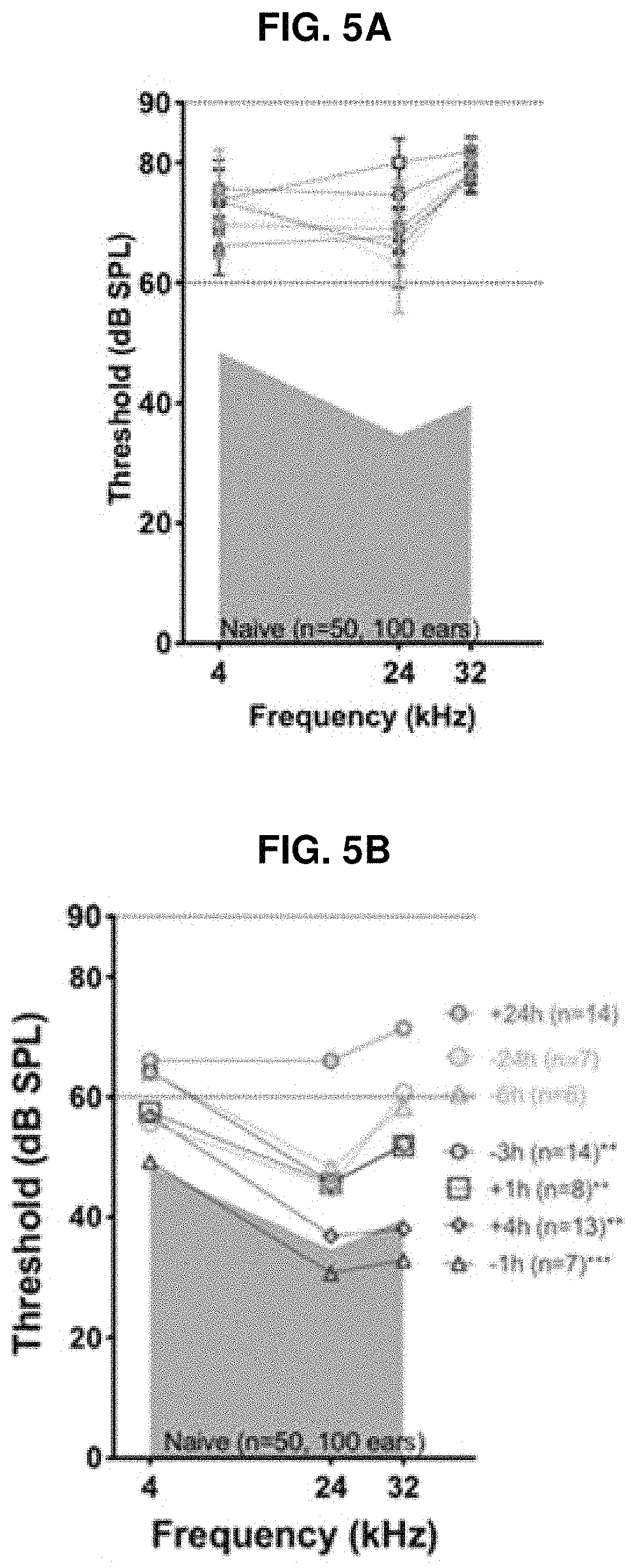

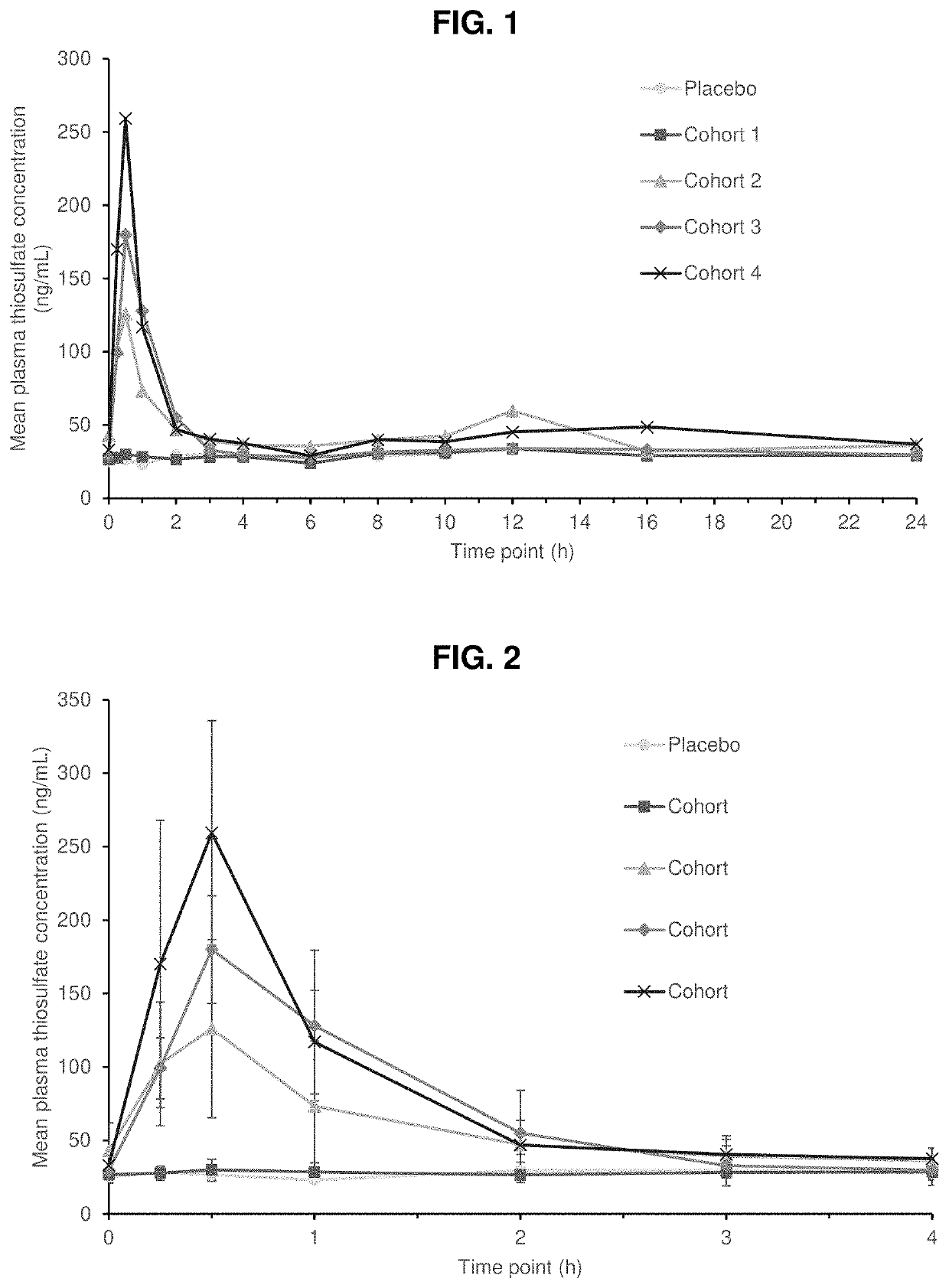

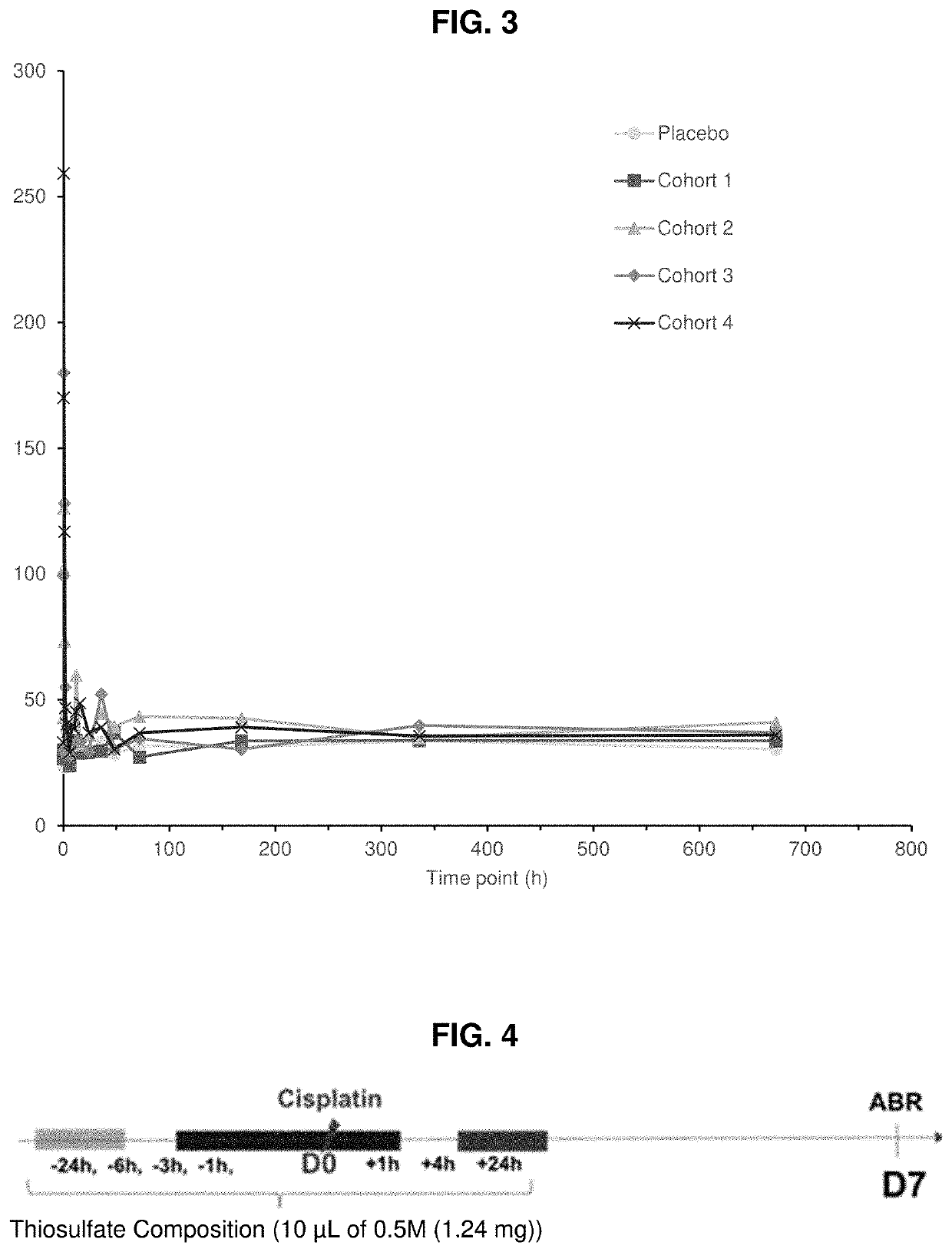

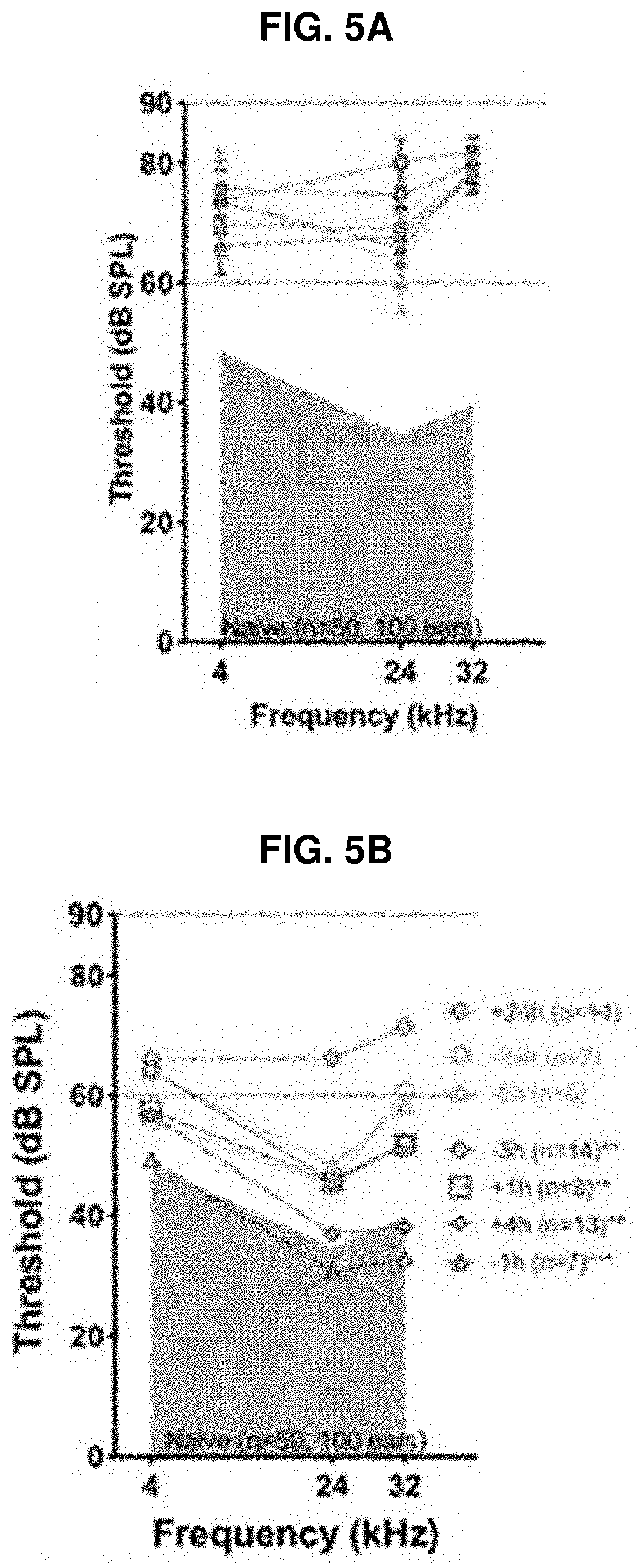

Methods of otoprotection against platinum-based antineoplastic agents

ActiveUS10813947B1Mitigating platinum-induced ototoxicitySenses disorderOintment deliveryPlatinumThio-

Disclosed herein are methods for otoprotection against platinum-based antineoplastic agents by administering a thiosulfate salt to a subject in need thereof. Typically, the thiosulfate salt is administered to the subject scheduled to be administered a platinum-based antineoplastic agent within 4 hours. Alternatively, the thiosulfate salt is administered within 7 hours after the administration of a platinum-based neoplastic agent.

Owner:DECIBEL THERAPEUTICS INC

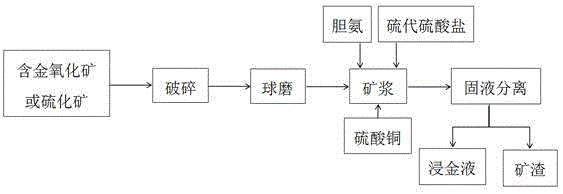

Gold leaching process of thiosulfate gold leaching system for replacing ammonia water by using cholamine

The invention discloses a gold leaching process of a thiosulfate gold leaching system for replacing ammonia water by using cholamine, belongs to the field of wet metallurgy technologies, and solves such problems as low leaching rate and environmental protection problem of ammonia water in nowadays popular thiosulfate gold leaching method in a targeted manner. The gold leaching process uses thiosulfate, cholamine and copper sulfate pentahydrate leaching liquid for stirring and leaching gold ores; the leaching rate can reach 85%; the method is simple; the raw materials are easily obtained; the cost is low; and the whole gold leaching process has no acute toxicant influence, has the environmental benefit, and can be preferably put in large-scale application.

Owner:FUZHOU UNIV

Copper-catalyzed glycine-thiosulfate composite gold leaching process

ActiveCN112961991AWeaken oxidative decompositionImprove stabilityProcess efficiency improvementSulfate radicalsThio-

The invention discloses a copper-catalyzed glycine-thiosulfate composite gold leaching process. The process comprises the following steps of adding copper sulfate, glycine or / and metal salt thereof and thiosulfate into gold ore pulp, adjusting the pH value of the ore pulp to 10.0-13.0, and then stirring and leaching to complete the gold leaching process. According to the process, in the copper-catalyzed glycine-thiosulfate composite gold leaching process, the glycine or the metal salt thereof is introduced, the glycine or the metal salt thereof can form a copper-glycine chelate with higher stability with Cu<2+> to stabilize copper in a solution, so that the oxygenolysis effect of a copper complex on thiosulfate radicals is weakened, the stability of a gold leaching system is improved, and the consumption of reagents is reduced; and the glycine or the metal salt of the glycine can also play a role of the gold leaching agent together with thiosulfate radicals, so that the consumption of thiosulfate can be further effectively reduced, and the consumption of thiosulfate is reduced to be below 4kg / t gold ore.

Owner:JIANGXI UNIV OF SCI & TECH

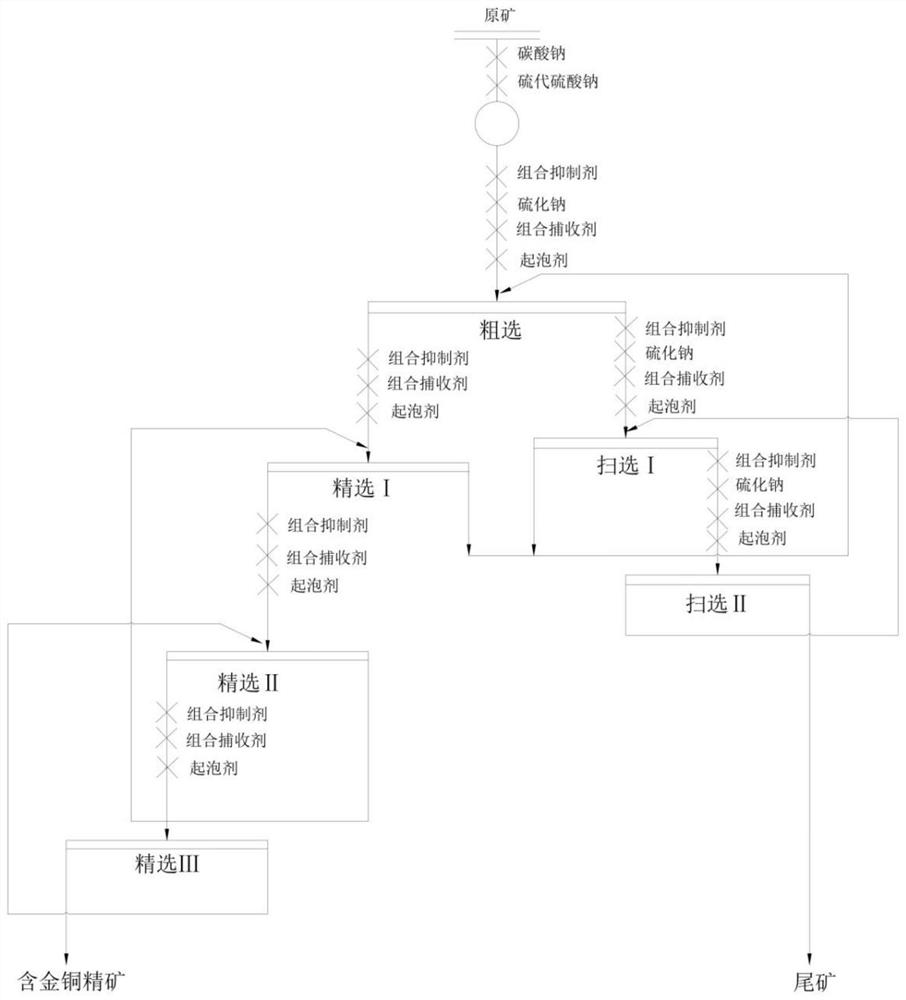

Flotation method for improving beneficiation index of gold-bearing copper sulfide ore

ActiveCN114011582AEconomical and Clean Development and UtilizationEfficient and clean development and utilizationFlotationMechanical material recoveryThio-Mining engineering

The invention discloses a flotation method for improving the beneficiation index of gold-bearing copper sulfide ore, and belongs to the technical field of metallurgical beneficiation. Based on the technical route of thiosulfate corrosion, sulfuration precipitation, hydrogen peroxide and starch coupled inhibition and copper and sulfur selective flotation separation, separation of the gold-containing copper sulfide ore is carried out. The flotation method comprises the following steps: (1) roughing; (2) scavenging I; (3) concentration I; (4) scavenging II; (5) concentration II; and (6) concentration III. By means of the flotation method, gold in carrier minerals can be converted into independent gold sulfide minerals, the situation that gold in pyrite is lost into tailings is avoided, the synergistic benefit of the combined inhibitor is fully exerted, the quality and the recovery rate of gold and copper concentrates are improved, and economical, efficient and clean development and utilization of the gold-containing copper-sulfur ore are achieved under the low alkalinity condition.

Owner:KUNMING UNIV OF SCI & TECH

Methods of otoprotection against platinum-based antineoplastic agents

Disclosed herein are methods for otoprotection against platinum-based antineoplastic agents by administering a thiosulfate salt to a subject in need thereof. Typically, the thiosulfate salt is administered to the subject scheduled to be administered a platinum-based antineoplastic agent within 4 hours. Alternatively, the thiosulfate salt is administered within 7 hours after the administration of a platinum-based neoplastic agent.

Owner:DECIBEL THERAPEUTICS INC

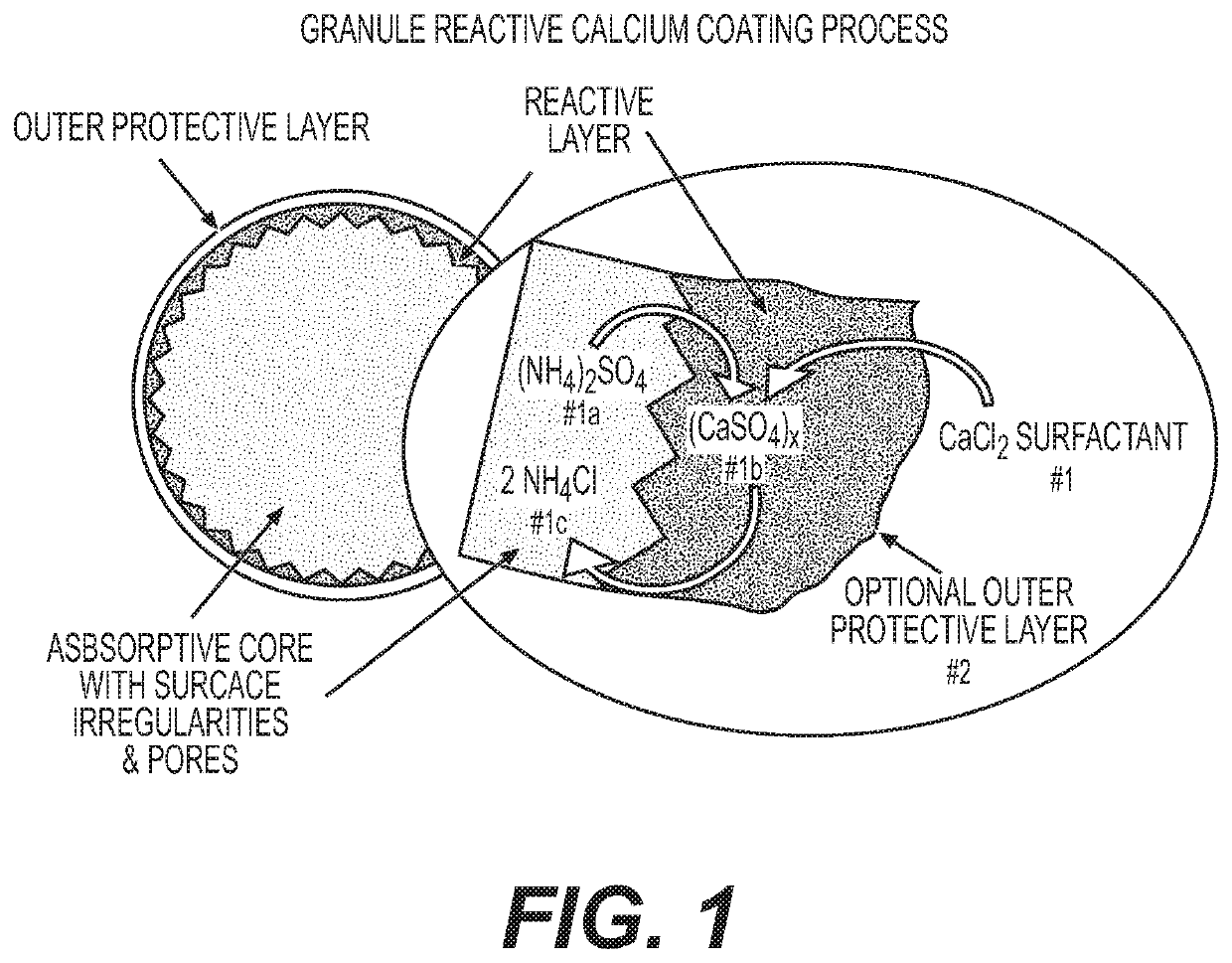

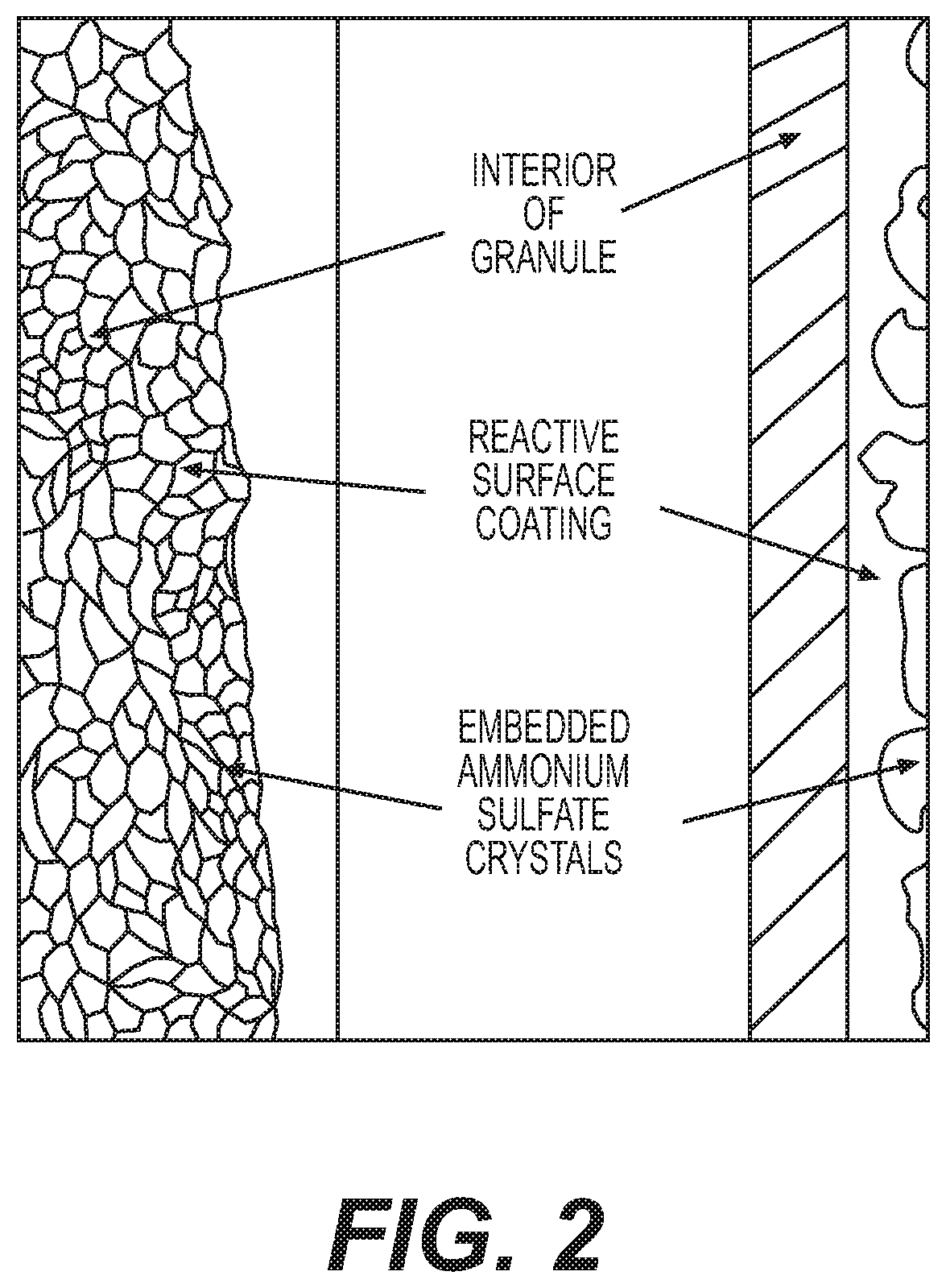

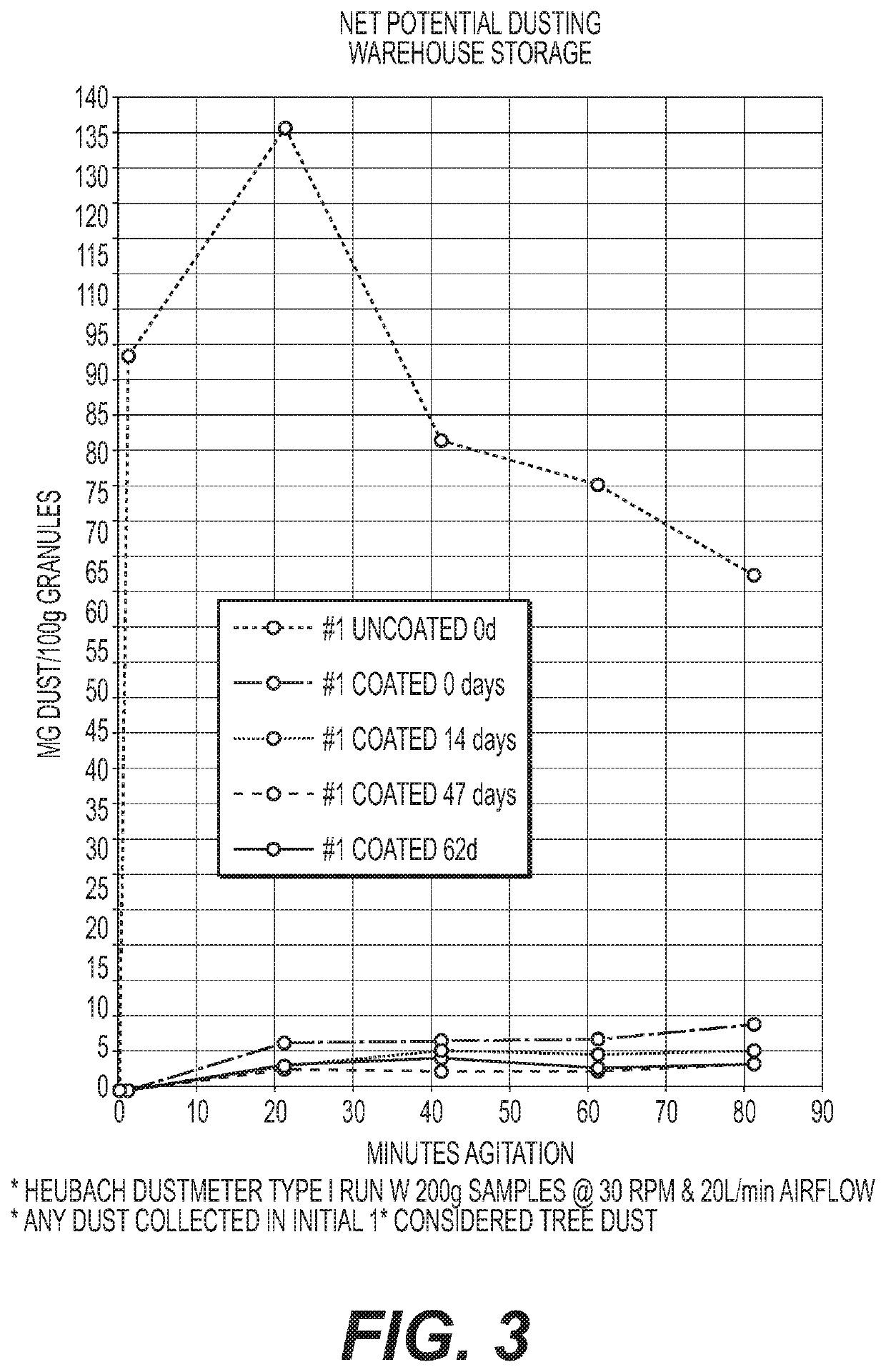

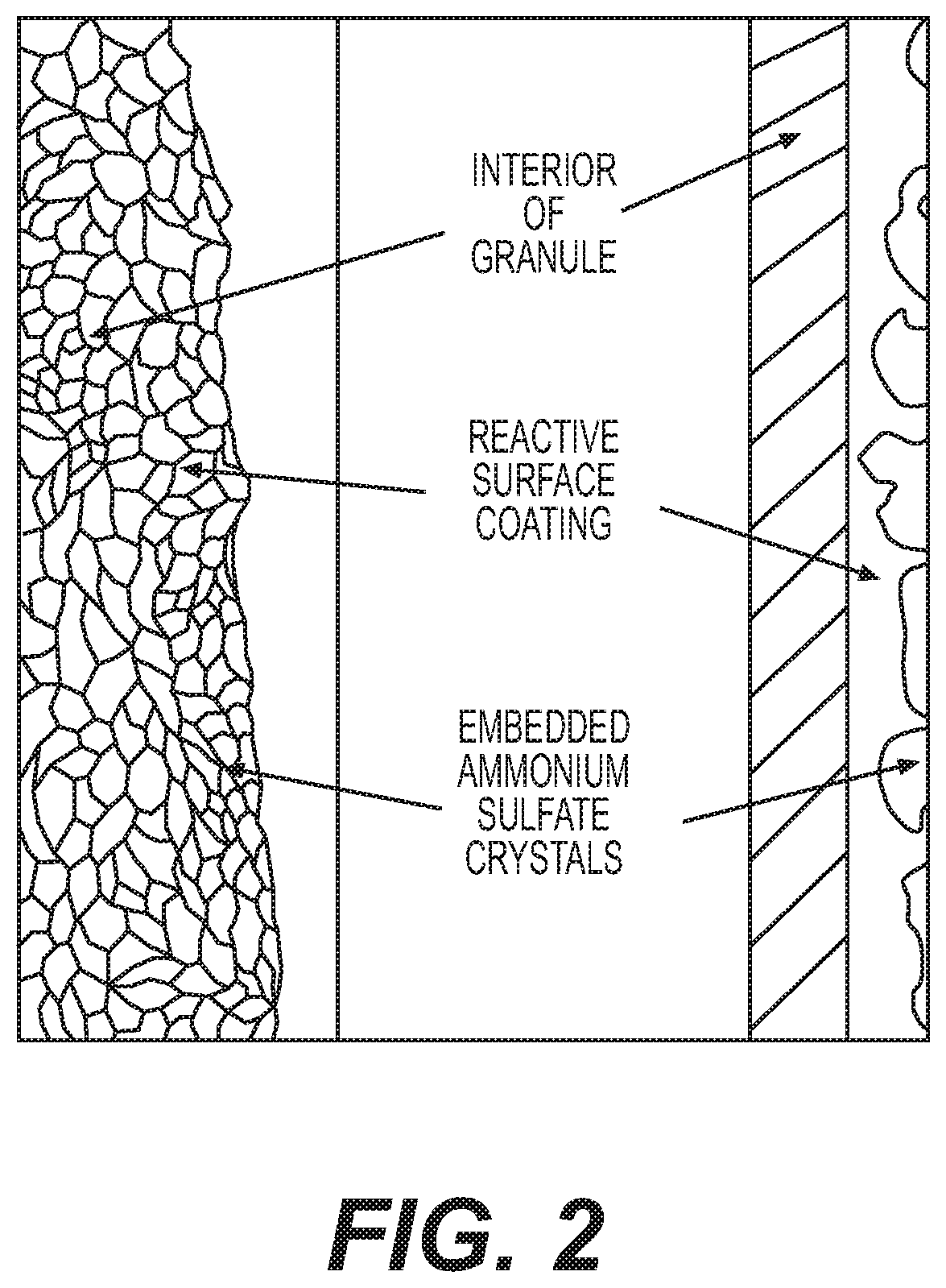

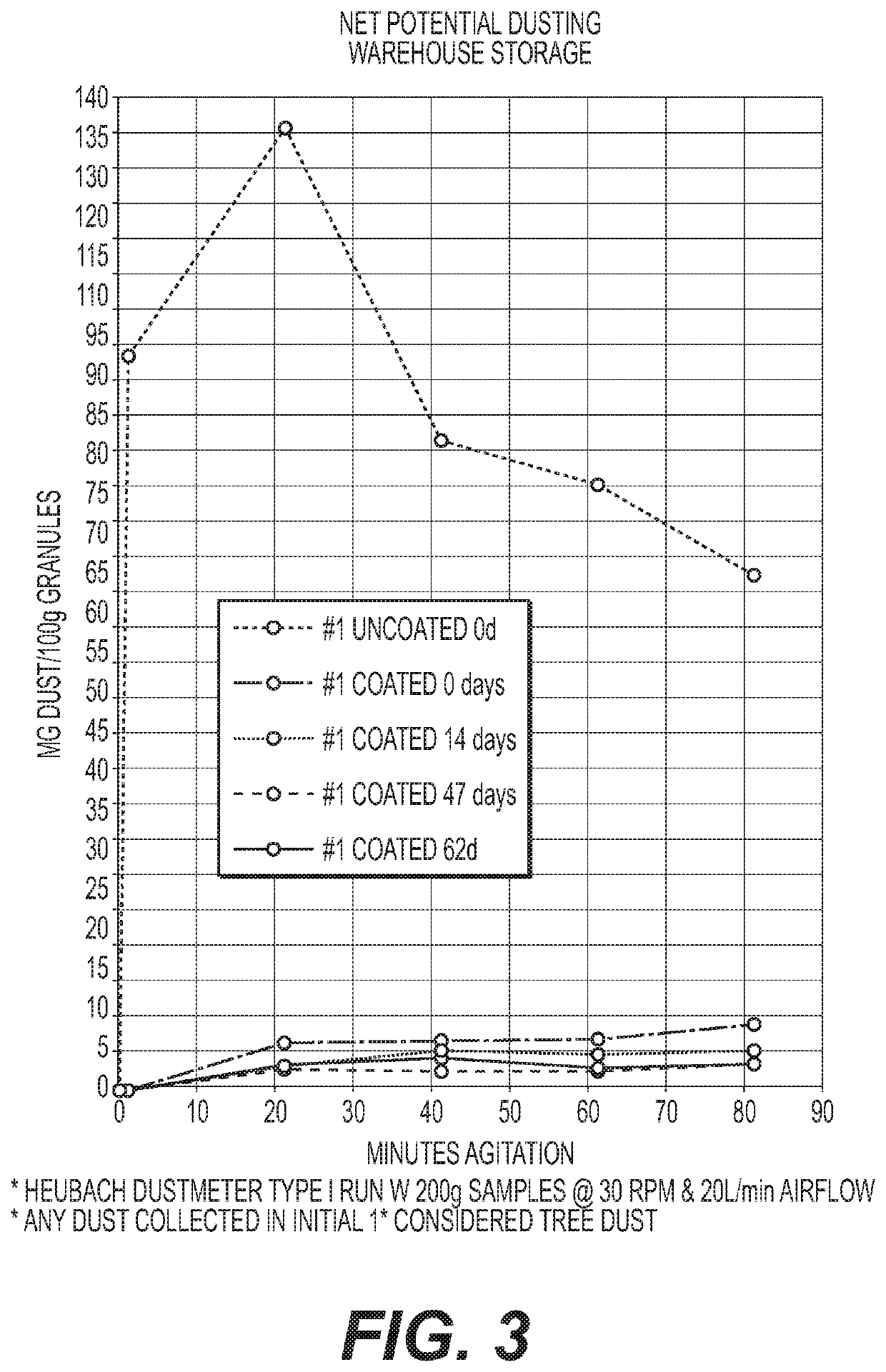

Reactive inorganic coatings for agricultural fertilizers

The invention relates to a coated granular fertilizer, preferably wherein granules are sulfate-based or phosphate-based. When sulfate based granules, as in ammonium sulfate, the coating substance is an inorganic salt of alkaline earth elements, preferably calcium, such that when applied to the surface of fertilizers, forms calcium sulfate, preferably a calcium sulfate-dihydrate, as a protective coating. For a reactive coating of a thiosulfate, free sulfuric acid present on the granule reacts to provide an elemental sulfur coating. For ammonium phosphate-based granules, coatings may comprise compounds of Ca++, Al+++ and / or Fe+++ salts thereby forming a calcium, an aluminum, an iron, or mixed cation phosphate protective coating. Thiosulfate is also effective with phosphate based granules which are manufactured with sulfuric acid. Granules coated according to the disclosure have advantageous properties as the coating can be applied in a specified and sparing manner due to its tendency to adhere to surfaces during the reaction. Coated fertilizer granules of the disclosure are also advantageous in that, with regard to the applied amount of coating, they provide increased resistance to dusting in long term warehouse storage, to moisture uptake and to oxidative heating. Coating components also add nutrients to plants that can provide nutrients over a longer period of time such as a slow-release characteristic.

Owner:GENERATE LENDING LLC +1

Reactive Inorganic Coatings for Agricultural Fertilizers

The invention relates to a coated granular fertilizer, preferably wherein granules are sulfate-based or phosphate-based. When sulfate based granules, as in ammonium sulfate, the coating substance is an inorganic salt of alkaline earth elements, preferably calcium, such that when applied to the surface of fertilizers, forms calcium sulfate, preferably a calcium sulfate-dihydrate, as a protective coating. For a reactive coating of a thiosulfate, free sulfuric acid present on the granule reacts to provide an elemental sulfur coating. For ammonium phosphate-based granules, coatings may comprise compounds of Ca++, Al+++ and / or Fe+++ salts thereby forming a calcium, an aluminum, an iron, or mixed cation phosphate protective coating. Thiosulfate is also effective with phosphate based granules which are manufactured with sulfuric acid. Granules coated according to the disclosure have advantageous properties as the coating can be applied in a specified and sparing manner due to its tendency to adhere to surfaces during the reaction. Coated fertilizer granules of the disclosure are also advantageous in that, with regard to the applied amount of coating, they provide increased resistance to dusting in long term warehouse storage, to moisture uptake and to oxidative heating. Coating components also add nutrients to plants that can provide nutrients over a longer period of time such as a slow-release characteristic.

Owner:GENERATE LENDING LLC

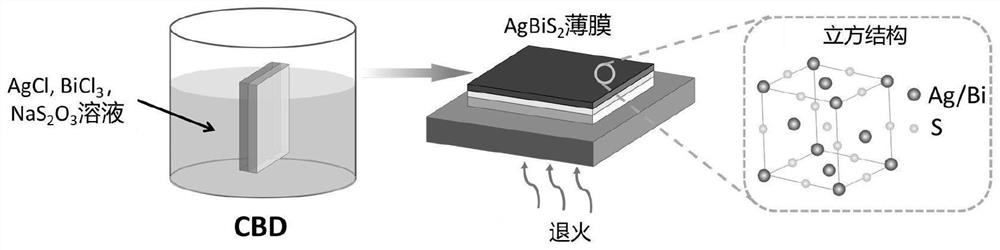

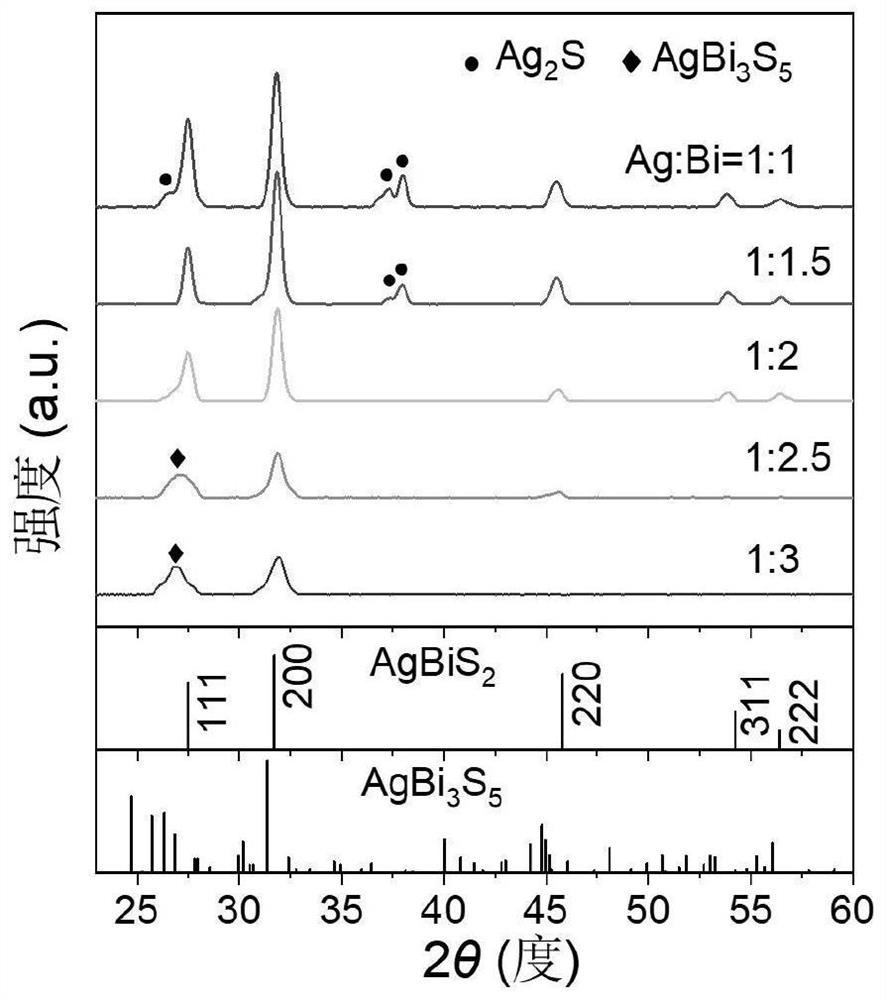

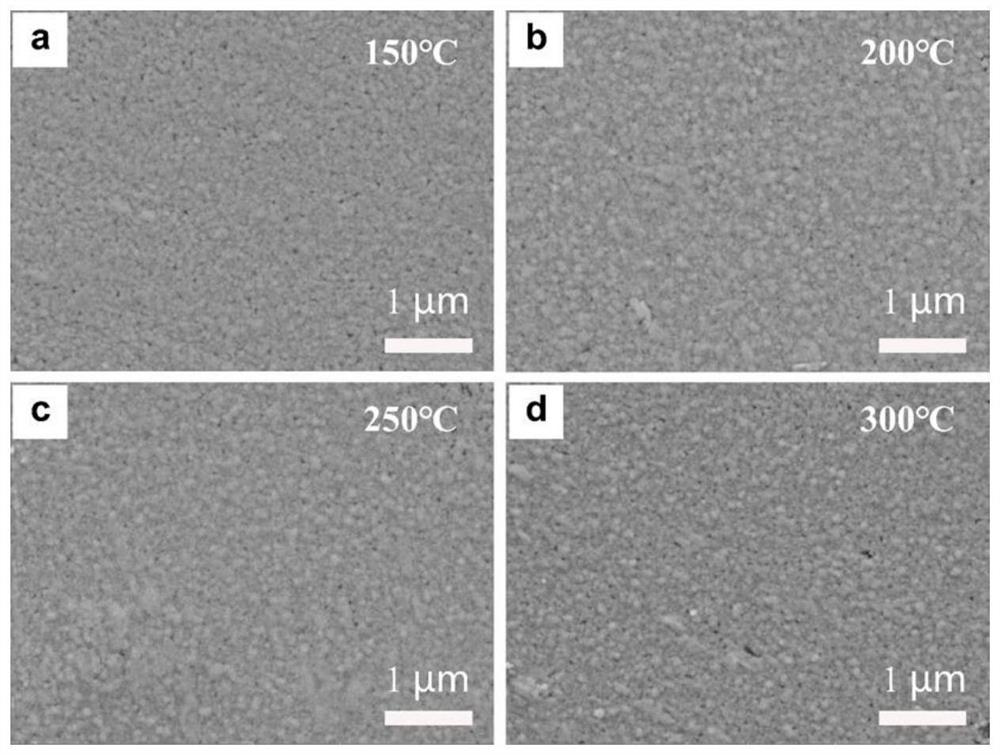

AgBiS2 film and preparation method and application thereof

ActiveCN113913794AThickness is easy to controlComposition controllableFinal product manufactureSolid-state devicesThio-Physical chemistry

The invention relates to an AgBiS2 film and a preparation method and application thereof. The preparation method comprises the following steps that soluble silver salt and soluble bismuth salt are added into water according to the molar ratio of Ag to Bi being 1: 1-3, soluble thiosulfate with the sulfur molar weight not lower than the sum of Ag and Bi is added, after even mixing is conducted, acid is added to adjust the pH value to be 3, and a precursor solution is obtained; in the precursor solution, cations of the soluble thiosulfate, the soluble silver salt, the soluble bismuth salt and anions of acid do not participate in the deposition reaction; a substrate is placed in the precursor solution, standing and depositing are conducted at 80 + / -5 DEG C for at least 30 minutes, and the substrate is taken out; and the substrate is annealed in air at the temperature of 80-300 DEG C to obtain the substrate attached with the AgBiS2 film. The preparation method has the advantages of simplicity in operation, mild reaction conditions, low cost, low requirements on equipment and environment and the like, and the prepared AgBiS2 film is high in quality, good in optical and electrical performance, good in photovoltaic performance and good in detection performance and has great application potential in the photoelectric field.

Owner:WUHAN UNIV

Non-toxic and non-corrosive heating water odorant

InactiveCN111233179AImprove odor persistenceStrong pungent odorWater treatment locationTreatment using complexing/solubilising chemicalsWater useWater leak

The invention relates to the field of heating water treatment, in particular to a non-toxic and non-corrosive heating water odorant. The heating water odorant at least comprises the following components in parts by weight: 40-60 parts of starch, 10-20 parts of allicin, 10-15 parts of mercaptan, 5-10 parts of thiosulfate, 25-35 parts of an alkaline agent and 15-25 parts of water. The prepared non-toxic and non-corrosive heating water odorant is widely applied to hot water boilers, pipe networks for heat supply of various heat exchangers and the like to form an intensive irritating stinky smell.The water odorant has easy operation, wherein the softening and stabilizing effects are achieved on the water quality; when leakage happens to the pipeline, the pipeline cannot be blocked, easily sniffing by people, the water leakage phenomenon is found, the maintenance progress is accelerated, and no corrosion is caused to copper, aluminum, stainless steel and the like existing in the heat distribution pipeline. By means of the water odorant, heating equipment damage caused by excessive corrosion of products can be avoided, manual system water loss can be thoroughly prevented, the heat distribution pipeline is an ideal energy-saving agent for preventing hot water loss, and the heating water cost and the fuel consumption cost are effectively reduced.

Owner:延边群益科技发展有限责任公司

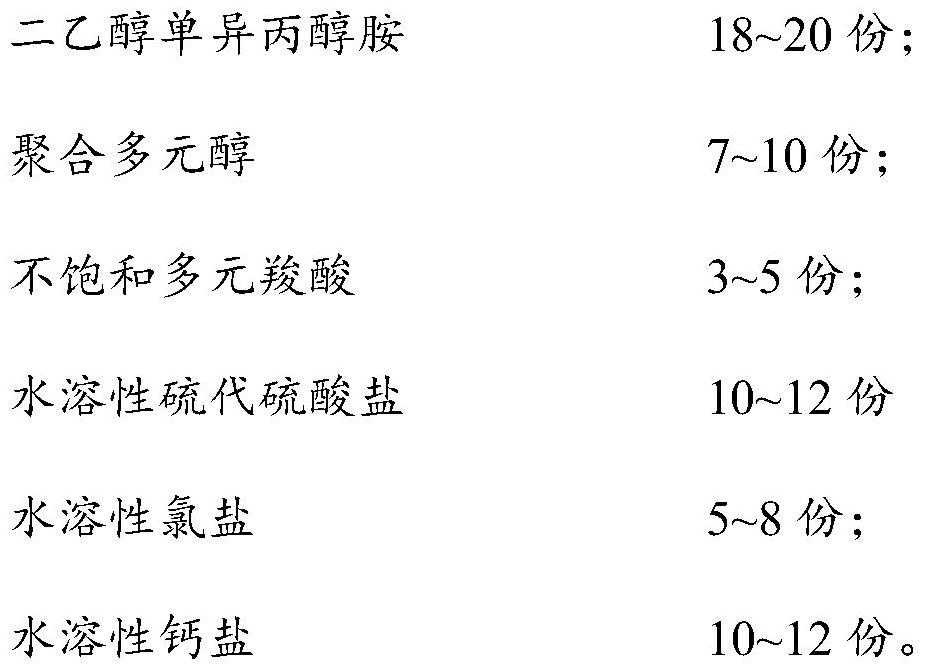

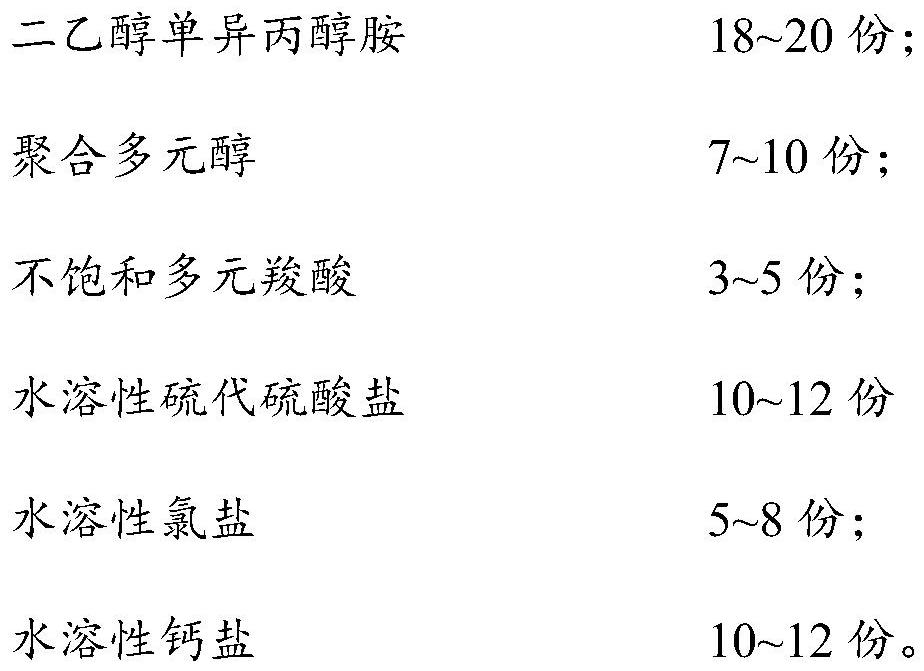

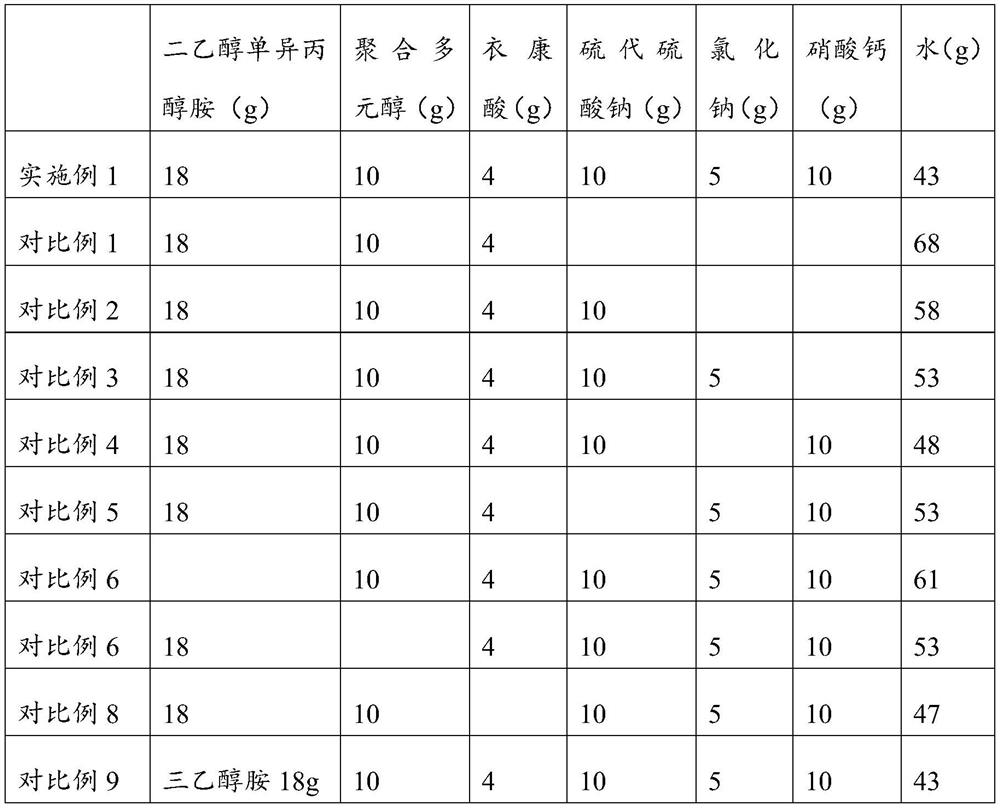

Grinding aid as well as preparation method and application thereof

The invention discloses a grinding aid as well as a preparation method and application thereof, and belongs to the technical field of building materials. The grinding aid is prepared from the following raw materials: diethanolisopropanolamine, polymeric polyol, unsaturated polycarboxylic acid, water-soluble thiosulfate, water-soluble chlorine salt and water-soluble calcium salt. According to the grinding aid provided by the invention, through matching of the raw material components, when the grinding aid is applied to cement preparation, the early strength of the obtained cement can be improved on the premise of ensuring the grinding efficiency.

Owner:HUNAN ZHONGYAN BUILDING MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com