Gold leaching process of thiosulfate gold leaching system for replacing ammonia water by using cholamine

A technology of thiosulfate and copper sulfate pentahydrate is applied in the fields of environment and hydrometallurgy, and can solve the problems of large consumption of thiosulfate, high treatment efficiency, environmental pollution of ammonia water, etc. Fast, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

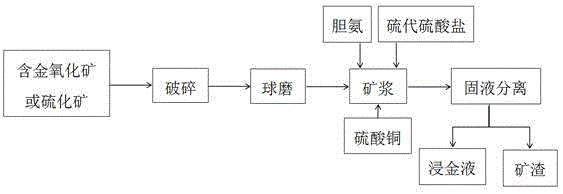

Image

Examples

Embodiment 1

[0025] Ball mill the gold ore until the ore fineness is -200 mesh, add deionized water to adjust the slurry concentration to 30wt%; add copper sulfate pentahydrate, ammonium thiosulfate, and cholamine to 0.03mol / L, 0.3mol / L, and 0.6mol respectively / L, the stirring speed is 300r / min, leaching for 24h, the leaching rate of gold increases to 77.9%, and the consumption of ammonium thiosulfate decreases to 22.3kg / t.

Embodiment 2

[0027] Ball mill the gold ore until the ore fineness is -200 mesh, add deionized water to adjust the pulp concentration to 30wt%; add copper sulfate pentahydrate, ammonium thiosulfate, and cholamine to 0.03mol / L, 0.3mol / L, and 0.8mol respectively / L, stirring speed is 300r / min, leaching for 24h, the leaching rate of gold is increased to 79.6%, and the consumption of ammonium thiosulfate is reduced to 21.6kg / t.

Embodiment 3

[0029] Ball mill the gold ore until the ore fineness is -200 mesh, add deionized water to adjust the pulp concentration to 30wt%; add copper sulfate pentahydrate, ammonium thiosulfate, and cholamine to 0.03mol / L, 0.3mol / L, and 1mol / L respectively L, the stirring speed is 300r / min, leaching for 24h, the leaching rate of gold is increased to 81.1%, and the consumption of ammonium thiosulfate is reduced to 19.9kg / t.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com