AgBiS2 film and preparation method and application thereof

A thin-film and soluble technology, which is applied in semiconductor/solid-state device manufacturing, liquid chemical plating, organic semiconductor devices, etc., can solve the problems of preparation phase and singleness, and achieve a shape without holes, low energy consumption, and dense films. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

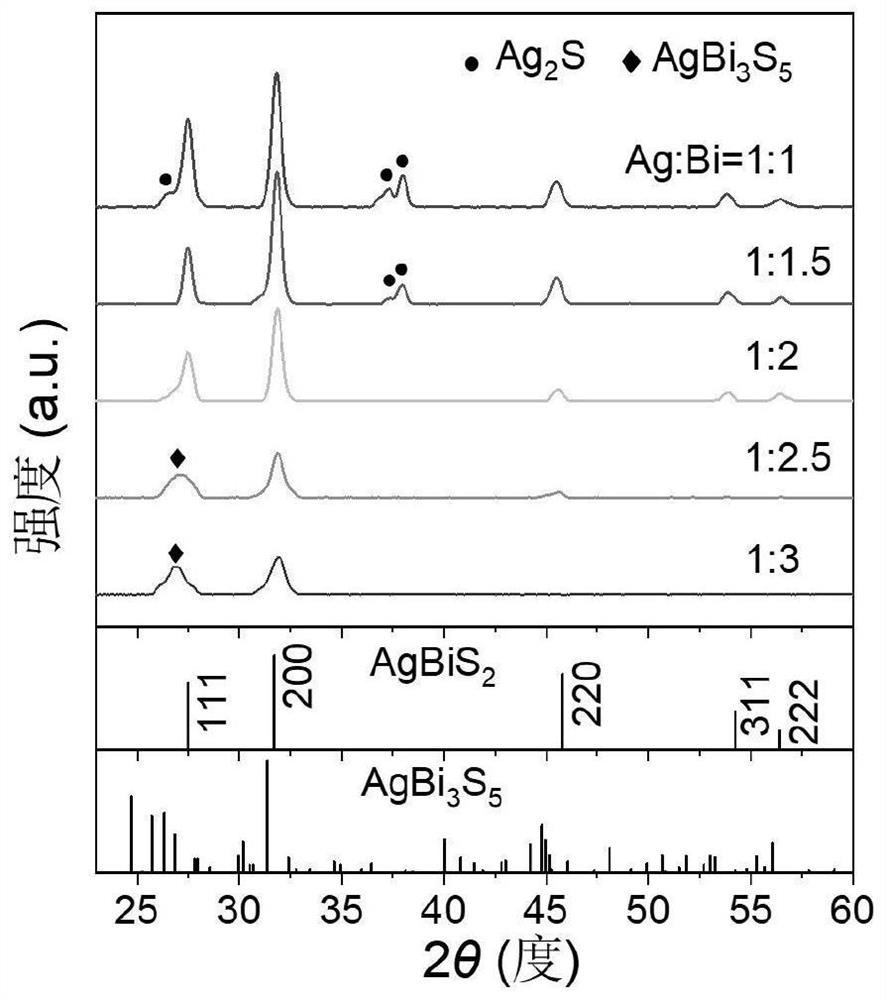

[0036] We first studied Ag 2 S and Bi 2 S 3 film deposition rate, found Ag 2 S grows faster than Bi 2 S 3 much faster. Based on this result, we carefully adjusted the molar ratio of Ag and Bi in the precursor solution.

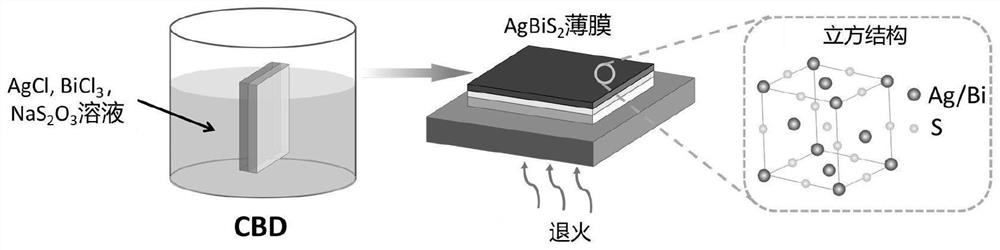

[0037] (1) AgCl and BiCl were mixed according to Ag and Bi molar ratios of 1:1, 1:1.5, 1:2, 1:2.5, 1:3 respectively 3 dissolved in deionized water (Ag + Concentration is 0.002mol / L), get 5 parts of metal salt aqueous solution;

[0038] (2) Press S 2 o 2 2- Concentration is 0.02mol / L Na 2 S 2 o 2 ·5H 2 O was added to each part of the metal salt aqueous solution, fully stirred until the solid was completely dissolved;

[0039] (3) Adding hydrochloric acid to the solution obtained in step (2) respectively, adjusting the pH value to 3 to obtain a precursor solution;

[0040] (4) Completely immerse the conductive substrates deposited with the CdS thin film by chemical bath deposition in each precursor solution, and maintain the temperature of the pr...

Embodiment 2

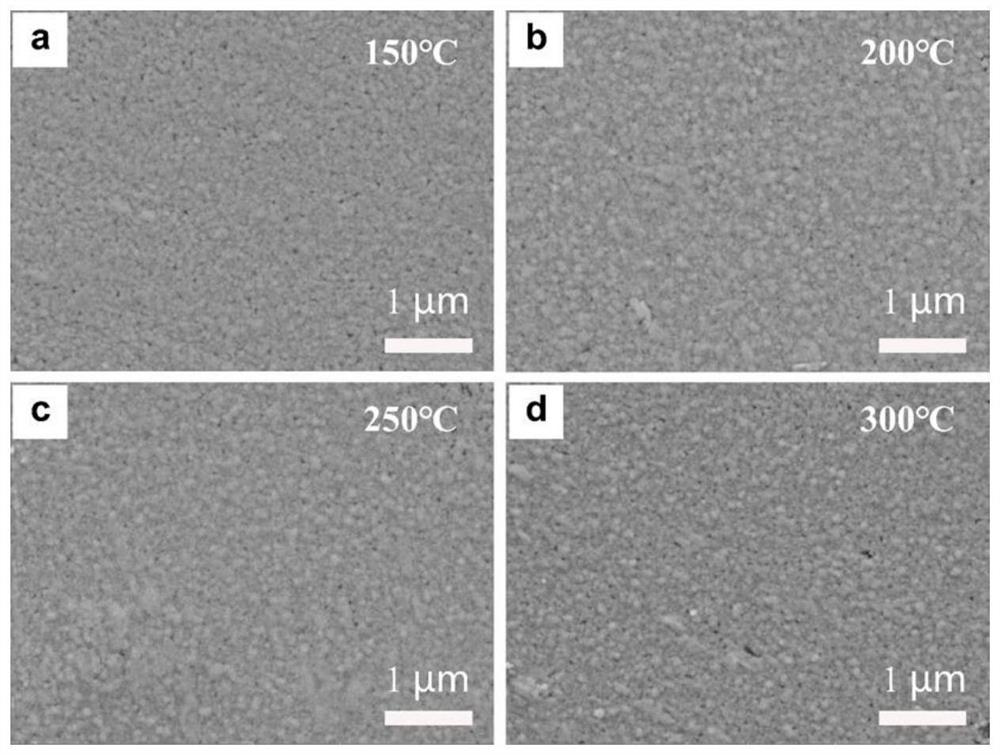

[0044] The preparation AgBiS that this embodiment provides 2 The method of the thin film is basically the same as in Example 1, the only difference is that in this example, the molar ratio of Ag and Bi is controlled to be 1:2, and the annealing temperature (150°C, 200°C, 250°C, 300°C) in step (5) is changed. ℃, 350℃, 400℃).

[0045] Such as image 3 As shown, the higher the annealing temperature, the larger the grain size; Figure 4 As shown, it can be seen from the XRD pattern of the film that AgBiS has formed at 80 °C 2 phase; as the annealing temperature increased to 300 °C, AgBiS 2 The characteristic peaks are obviously enhanced. However, with the further increase of annealing temperature, AgBiS 2 The characteristic peaks decreased significantly, and Ag 5 BiO 4 phase, indicating that AgBiS 2 After the deterioration and degradation of the crystal phase, the composite oxide of Ag and Bi is formed, and the annealing temperature is too high will cause AgBiS 2 High tem...

Embodiment 3

[0047] The preparation AgBiS that this embodiment provides 2 The method of thin film is basically the same as Example 1, and the only difference is that the present embodiment controls the Ag, Bi molar ratio to be 1:2, and changes the time (0.5 hours, 1 hour, 1.5 hours) of static deposition in step (4). ,2 hours). Such as Figure 5 As shown, AgBiS 2 The thickness of the film has a linear relationship with the static deposition time, which proves that the preparation of AgBiS provided by this embodiment 2 Thin-film approach enables precise tuning of AgBiS 2 Thickness of the film. The method provided in this example can prepare AgBiS with a thickness of 90 nm within 2 hours. 2 Compared with the traditional quantum dot preparation method, the preparation efficiency of thin film is greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystal size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com