Oxidizing roasting-microwave-assisted leaching gold extraction method for high-arsenic gold-bearing sulfur concentrate

A microwave-assisted, oxidative roasting technology, applied in the direction of improving process efficiency, etc., to achieve the effects of fast heating speed, short leaching cycle, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

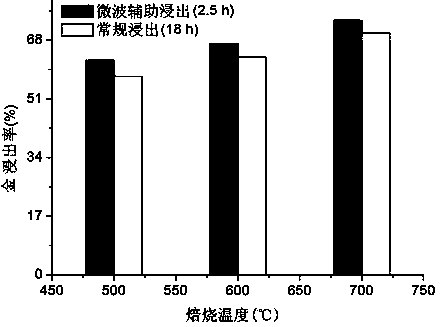

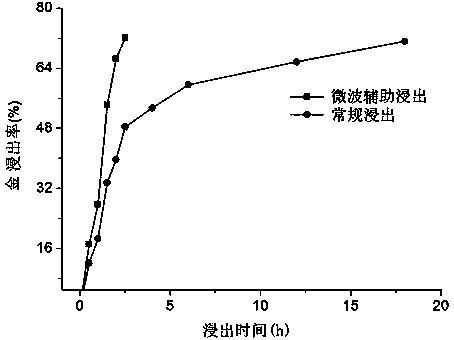

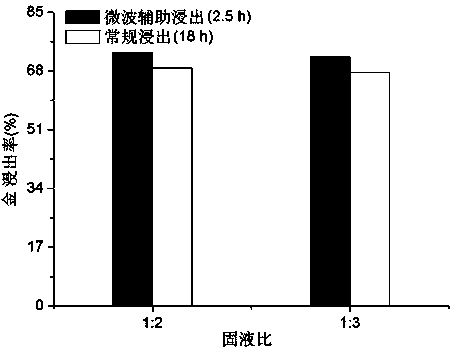

[0030] Spread the high-arsenic gold-sulfur concentrate in a quartz boat, then put the quartz boat into a box-type resistance furnace with a power of 4 kW, and set the temperature of the box-type resistance furnace at 500-700°C. After 2 hours of lower roasting, the quartz boat containing the high-arsenic gold-sulfide concentrate was taken out. After the high-arsenic gold-sulfur concentrate is cooled, weigh it to calculate the ore weight loss rate. Then weigh 0.48 g CuSO 4 , 4.74 g NaS 2 o 3 , 1.32 g (NH 4 ) 2 SO 4 , 0.378 g Na 2 SO 3 , and measure 7.5 mL of 15 % NH 3 h 2 O, add 100 mL of distilled water together to get 0.3 mol / L NaS 2 o 3 , 0.03 mol / L CuSO 4 , 1.0 mol / L NH 3 h 2 O, 0.1 mol / L (NH 4 ) 2 SO 4 , 0.3 mol / L Na 2 SO 3 of thiosulfate solution. Then mix the roasted high-arsenic gold-containing sulfur concentrate and the prepared thiosulfate solution according to the solid-to-liquid ratio of 1:2-1:3, put them in a microwave device, and set the microwa...

specific Embodiment approach

[0048] A high-arsenic gold-containing sulfur concentrate oxidative roasting-microwave assisted leaching gold extraction method, the specific steps are:

[0049] (1) Spread 30 g of high-arsenic gold-containing sulfur concentrate in a quartz boat, then place the quartz boat in a box-type resistance furnace with a power of 4 kW, and set the temperature of the box-type resistance furnace at 500-700 After roasting for 2 h under these conditions, the quartz boat containing the high-arsenic gold-containing sulfur concentrate was taken out. After the ore is cooled, it is weighed and the weight loss rate of the ore is calculated.

[0050] (2) Weigh 0.48 g CuSO 4 , 4.74 g NaS 2 o 3 , 1.32 g (NH 4 ) 2 SO 4 , 0.378 g Na 2 SO 3 , and measure 7.5 mL of 15 % NH 3 h 2 O, add 100 mL of distilled water together to get 0.3 mol / L NaS 2 o 3 , 0.03 mol / L CuSO 4 , 1.0 mol / L NH 3 h 2 O, 0.1 mol / L (NH 4 ) 2 SO 4 , 0.3 mol / L Na 2 SO 3 of thiosulfate solution. Then 10 g of the roast...

Embodiment 1

[0053] Example 1, spread 30 g of high-arsenic gold-containing sulfur concentrate in a quartz boat, then place the quartz boat in a box-type resistance furnace with a power of 4 kW, and set the temperature of the box-type resistance furnace to 500 °C , after roasting under this condition for 2 h, the quartz boat containing the high-arsenic gold-sulfur concentrate was taken out. After the ore is cooled, it is weighed, and the ore weight loss rate is 24.5%.

[0054] Add 10 g of the prepared thiosulfate solution with a weight loss rate of 24.5% and 20 mL into the Erlenmeyer flask (the ratio of solid to liquid is 1:2), and fix the Erlenmeyer flask with a rubber stopper in a constant temperature incubator. The temperature of the constant temperature incubator was set at 50 °C, and the rotation speed was set at 250 rpm. Under this condition, it was shaken and leached for 18 h and then taken out. The high-arsenic gold-sulfur concentrate was filtered and dried at 105 °C for 2 h. Gold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com