Sulfur and phosphorous-containing extreme pressure anti-wear reagent and preparation method and application thereof

An extreme pressure anti-wear agent, phosphate technology, applied in additives, petroleum industry, lubricating compositions, etc., can solve the problem of difficult and few parts cleaning, achieve excellent extreme pressure anti-wear performance, good biodegradability , the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

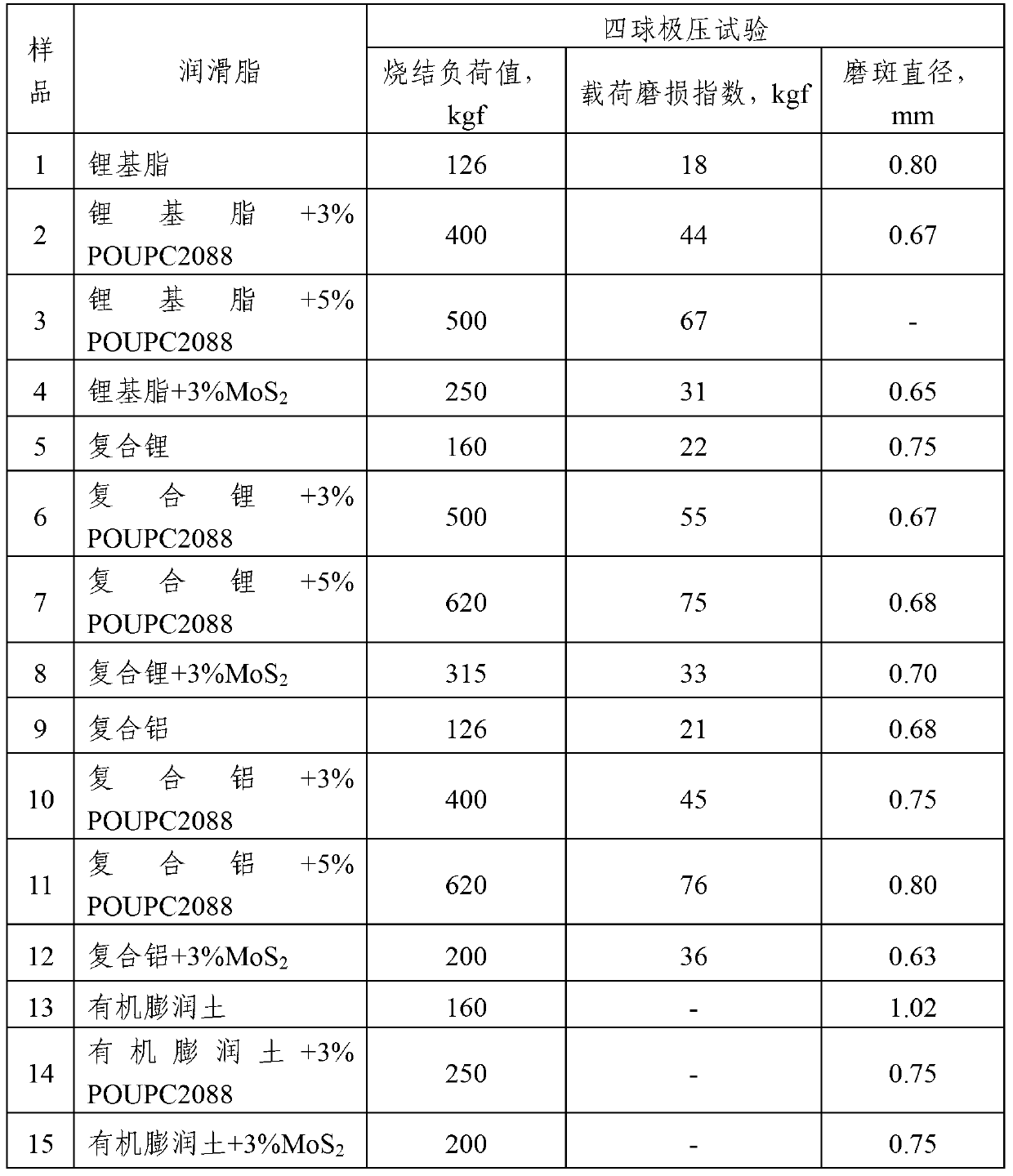

[0019] Example 1 Preparation of sulfur-containing phosphorus extreme pressure antiwear agent

[0020] The weight ratio of each component is as follows: sodium thiosulfate: sodium pyrophosphate is 70:30, and its preparation method is to achieve micron-level particles through physical grinding, and fully mix them in proportion for use.

Embodiment 2

[0021] Example 2 Preparation of sulfur-containing phosphorus extreme pressure antiwear agent

[0022] The weight ratio of each component is as follows: calcium thiosulfate: sodium monohydrogen phosphate is 70:30, and its preparation method is the same as above.

Embodiment 3

[0023] Example 3 Preparation of sulfur-containing phosphorus extreme pressure antiwear agent

[0024] The weight proportion of each component is as follows: sodium thiosulfate and ammonium phosphate are 60:40, and the preparation method is the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com