Grinding aid as well as preparation method and application thereof

A grinding aid and unsaturated technology, applied in the field of grinding aid and its preparation, can solve the problems of high cost of grinding aid, difficulty in taking into account early strength and late strength, and difficulty in large-scale promotion and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment has prepared a kind of grinding aid, and concrete process is:

[0044] S1. Weigh 10 g of sodium thiosulfate, 5 g of sodium chloride, 10 g of calcium nitrate, and 43 g of water, add them to the reaction vessel, stir for 10 min to dissolve;

[0045] S2. Add 18 g of diethanol monoisopropanolamine, 10 g of polymeric polyol and 4 g of itaconic acid to the system obtained in step S1, perform low-frequency ultrasonic oscillation for 5 min (frequency is 50-80 Hz), and form a uniform mixed solution, which is the aid Abrasives.

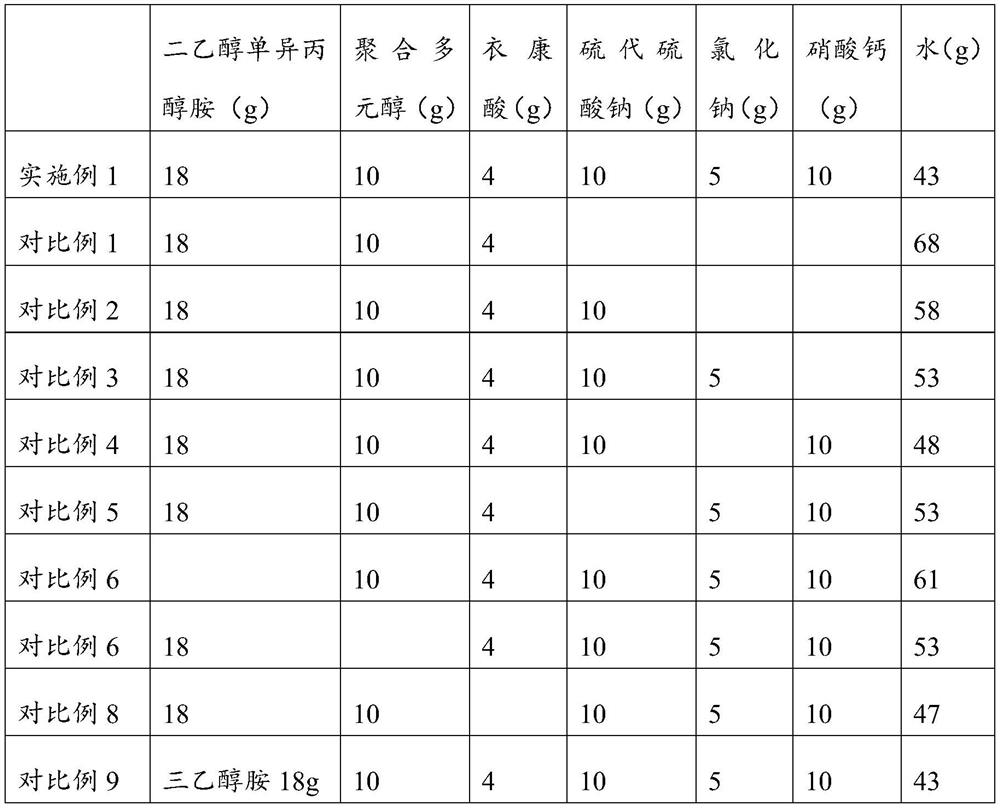

[0046] Comparative examples 1~9 prepared a kind of grinding aid respectively, and the difference of concrete process and embodiment 1 is:

[0047] (1) The specific components of the raw materials are different, and the specific components are shown in Table 1.

[0048]The raw material composition of grinding aid in table 1 embodiment 1 and comparative examples 1~9

[0049]

[0050] Wherein, the unfilled cells represent no add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com