Desulfurization and denitration carbon base fuel fume mercury absorbent and use thereof

A carbon-based coal-burning, desulfurization and denitrification technology, which is applied in other chemical processes, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high cost and low adsorption efficiency, achieve enhanced adsorption capacity, reliable system operation, and enhanced The effect of shape transformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0022] Sodium chloride and sodium thiosulfate are made into a 0.05mol / l solution in a ratio of 1:10 as a solution of a modifying reagent, and the activated carbon is soaked for 1 hour, and then dried naturally to obtain a modified carbon-based soot gas mercury sorbent. The stoichiometric ratio of chemical modification reagent to activated carbon is 1:2000.

preparation example 2

[0024] Potassium chloride and sodium thiosulfate were made into a 0.15mol / l solution in a ratio of 1:5 as the solution of the modifying reagent, and the activated carbon was soaked for 2 hours, and then dried naturally to obtain a modified carbon-based soot gas mercury sorbent. The stoichiometric ratio of chemical modification reagent to activated carbon is 1:200.

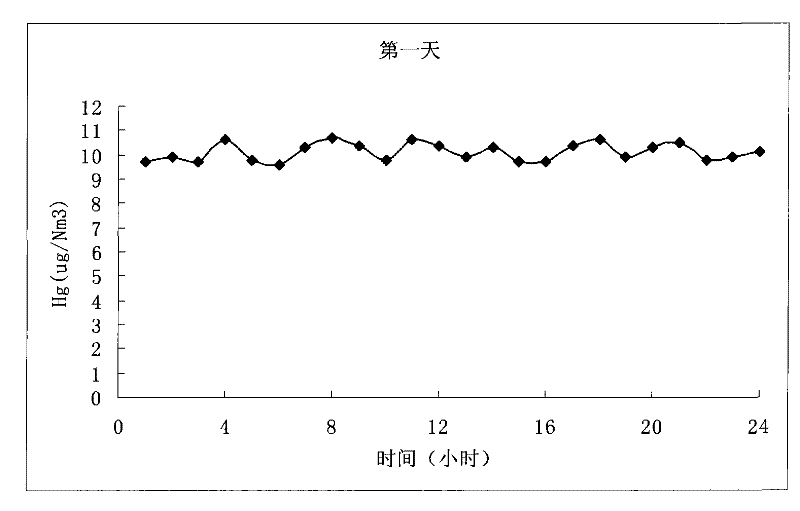

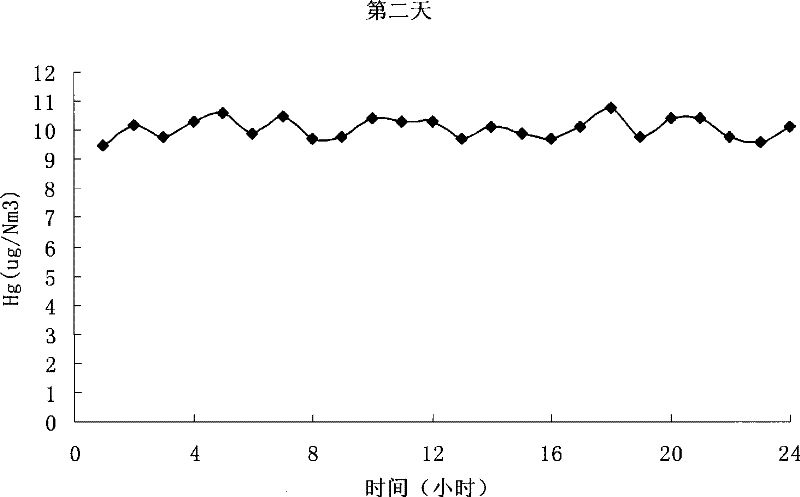

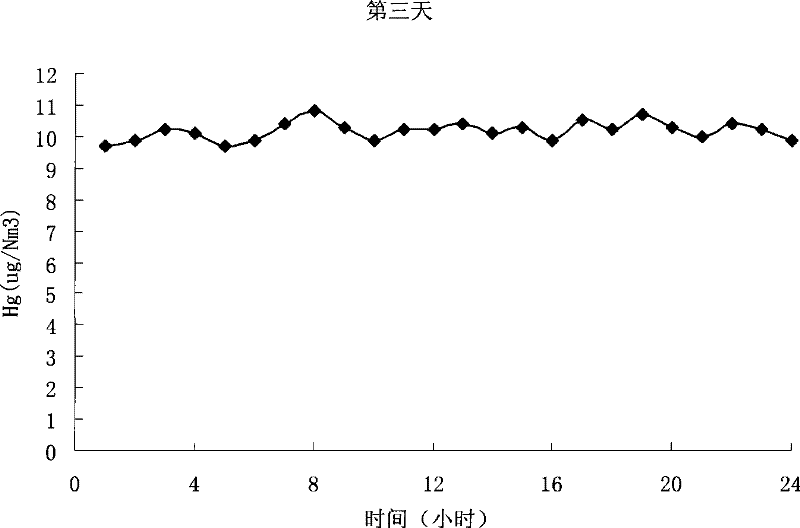

[0025] The adsorbent prepared in Example 2 has been carried out to carry out the experimental test of flue gas mercury adsorption effect. In the No. 2 furnace of a power plant in Kentucky, U.S., burning bituminous coal, this boiler is a 79MW unit, single furnace, negative pressure operation, π Shaped arrangement, burning coal powder. The power plant was established earlier without denitrification and desulfurization devices. The structure of the power plant is as follows: furnace - economizer - air preheater - electrostatic precipitator - chimney. A 12-day test was carried out, including 2 days for the conditiona...

Embodiment 4

[0029] Furnace No. 1 of a power plant in North Carolina, the United States, burns sub-bituminous coal. The boiler is a 125MW unit with a single furnace, negative pressure operation, π-shaped arrangement, and burns pulverized coal. The power plant was established earlier without a denitrification device. At the beginning, there was no desulfurization device. Later, a WFGD (wet desulfurization device) was added in 2001. The structure of the power plant during the test is as follows: Furnace—coal economizer—air preheater—— Electrostatic Precipitator - Desulfurization Island (WFGD) - Stack. Due to the increasingly stringent emission standards for flue gas from coal-fired power plant boilers in the United States, except for NO x with SO x In addition to the emission standards, the emission of heavy metal mercury in the flue gas of coal-fired power plant boilers has also been paid more and more attention, and corresponding regulations have been formulated. According to the time nod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com