Electrolyte of medium-voltage and high-voltage aluminium electrolytic capacitors and preparation method thereof

A technology of aluminum electrolytic capacitors and preparation methods, applied in the direction of electrolytic capacitors, capacitors, circuits, etc., to achieve the effects of less preparation links, short heating time, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

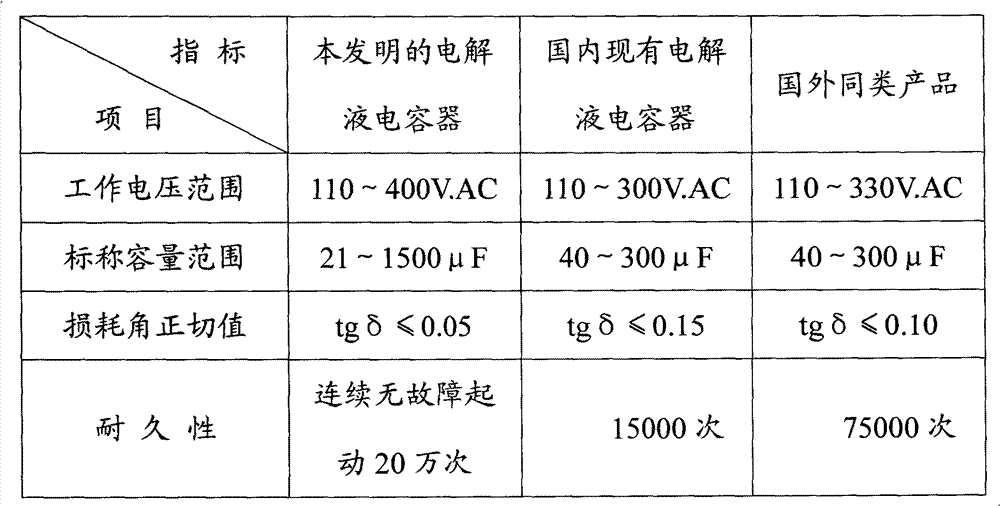

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be described in further detail below through the description of the embodiments, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

[0022] The invention relates to an electrolytic solution for a medium-high voltage aluminum electrolytic capacitor. In order to overcome the defects in the prior art and realize the invention goal of satisfying the EU REACH regulation on boric acid substances of high concern, the technical solution adopted by the present invention is as follows:

[0023] The components contained in the electrolyte of the medium and high voltage aluminum electrolytic capacitors and their proportions to the total mass are: ethylene glycol, 80%-82%; deionized water, 2%-3%; ammonium adipate, 10%- 11%; sebacic acid, 4% to 5%; p-nitrobenzoic acid, 0.20% to 0.25%; 2-4 dinitrophenol, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com