Working electrolyte solution of 800 V aluminum electrolytic capacitor and preparation method of working electrolyte solution

A technology of aluminum electrolytic capacitors and electrolytes, which is applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems of discounted service life of aluminum capacitors and other components, the inability to realize the miniaturization of the whole machine, and the reduction of the heat dissipation effect of the circuit board, etc., to achieve Superior electrical performance, complete crystal, and good product pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of working electrolyte for 800V ultra-high voltage (small) aluminum electrolytic capacitors:

[0024] The composition of each component is shown in Table 1. Mix and heat 63.5% ethylene glycol, 10.0% diethylene glycol-methyl ether, 5.8% diethylene glycol by mass percentage to 110-115°C, and add 2.0% polyethylene by mass percentage Alcohol and 3.0% polyethylene glycol 10000 were dissolved in a mixed solvent, and when cooled to 100°C, 5.8% by mass percentage of 11,12-diheptyl-10,12-docosadienedioxyl ammonium, 3.0% 2, 7-Dibutylpimelic acid, 3.4% dodecyl dioic acid, then cook at 100°C for 15-20 minutes under constant temperature and vacuum conditions, cool to 90°C and add 1.3% o-nitroanisole, 0.2% ammonium hypophosphite, and kept at 85°C for 60 minutes, and finally cooled to 70°C and added with 2.0% by mass of nano-silica sol to complete the preparation.

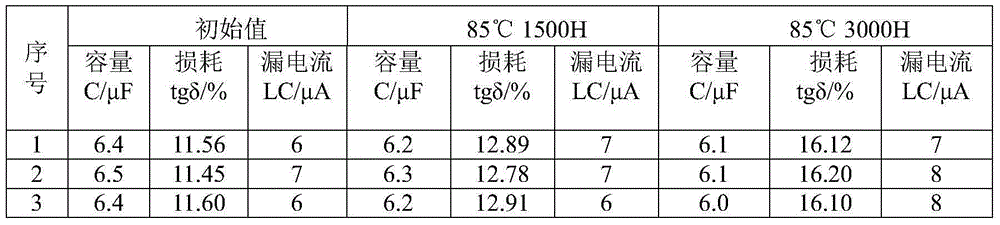

[0025] Table 2 shows the parameters and performance of the working electrolyte of the 800V ultra-high volta...

Embodiment 2

[0027] The preparation method of the working electrolyte of 800V ultra-high voltage (large product) aluminum electrolytic capacitor:

[0028] The composition of each component is shown in Table 1. Mix and heat 53.5% ethylene glycol, 19.4% diethylene glycol-methyl ether, 5.0% diethylene glycol by mass to 110-115°C, add 3.0% poly Vinyl alcohol and 3.0% polyethylene glycol 10000 were dissolved in a mixed solvent, and when cooled to 100°C, 4.0% by mass percentage of 11,12-diheptyl-10,12-docosadienedioxyl ammonium, 4.8% of 2 , 7-dibutylpimelic acid, 1.2% dodecyl dioic acid, then, cook at 100°C under constant temperature and vacuum conditions for 15-20 minutes, cool to 90°C and add 2.0% o-nitroanisole, 0.1% by mass % ammonium hypophosphite, and kept at 85°C for 60 minutes, and finally cooled to 70°C and added with 4.0% by mass of nano-silica sol to complete the preparation.

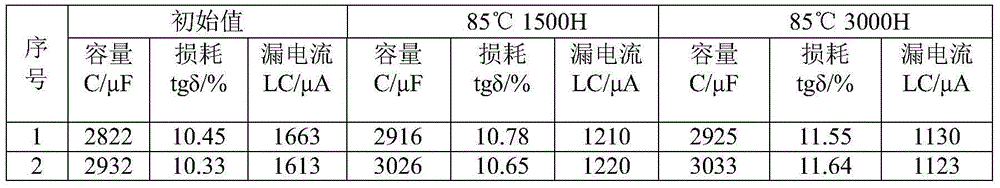

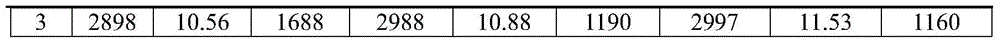

[0029] The parameters and performance of the working electrolyte of the 800V ultra-high voltage (large prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com