Electrolytic capacitor

An electrolytic capacitor and electrolyte technology, applied in the field of capacitors, can solve the problems of high heat generation, poor ripple current resistance, and low flashover voltage, and achieve the effects of high thermal stability, high oxidation efficiency, and long practical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

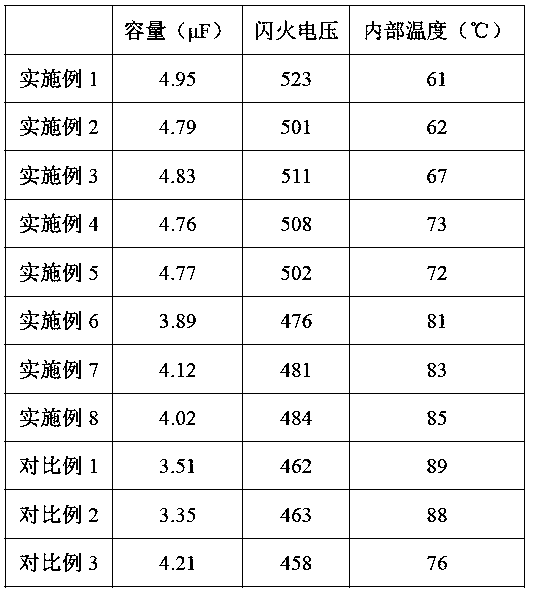

Examples

Embodiment 1

[0021] An electrolytic capacitor, comprising an anode formed by an aluminum foil with an aluminum oxide film on the surface, an aluminum foil cathode, a spacer and an electrolyte, the spacer is arranged in the electrolyte between the anode and the cathode; the electrolyte includes: 66 parts by mass of ethylene glycol, 5 parts by mass of modifier, 9 parts by mass of ammonium sebacate, 1.5 parts by mass of ammonium dodecanoate, 7.5 parts by mass of polyethylene glycol, and 3 parts by mass of auxiliary agent. The modifier is modified nano silicon dioxide. The preparation method of described modified nano silicon dioxide is: take 45 parts of absolute ethanol and 8 parts of deionized water, after mixing uniformly, stand-by, obtain absolute ethanol solution; Take 45 parts of 25% ammonia water; Take 6.9 parts of Ethyl orthosilicate and 40 parts of absolute ethanol are mixed evenly to obtain ethyl orthosilicate solution; the prepared absolute ethanol solution and ammonia water are hea...

Embodiment 2

[0025] Example 2 is different from Example 1 in that the electrolyte includes: 65 parts by mass of ethylene glycol, 1 part by mass of modifier, 8 parts by mass of ammonium sebacate, and 1 part by mass of ammonium dodecanoate , 5 parts by mass of polyethylene glycol, 2 parts by mass of auxiliary agent.

Embodiment 3

[0027] Embodiment 3 differs from Embodiment 1 in that the electrolyte includes: 70 parts by mass of ethylene glycol, 6 parts by mass of modifier, 10 parts by mass of ammonium sebacate, and 2 parts by mass of ammonium dodecanoate , polyethylene glycol 8 mass parts, auxiliary agent 4 mass parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com