Electrolyte of aluminum electrolytic capacitor and preparation method of solute thereof

A technology for aluminum electrolytic capacitors and electrolytes, which is applied in the field of preparation of electrolytes and their solutes, can solve the problems of poor low-temperature performance of electrolytic capacitors, small size, no more than 6% at room temperature, and affect the life of capacitors, etc., to achieve good low-temperature performance, Effect of high flash voltage and high flash voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

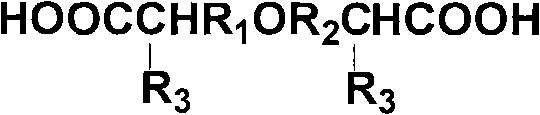

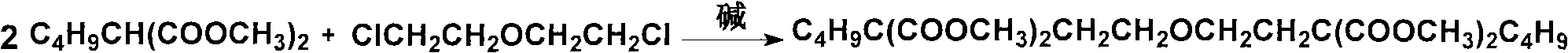

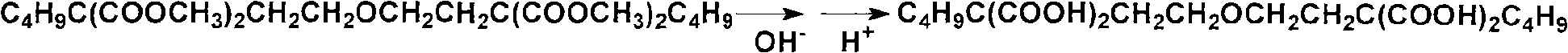

Method used

Image

Examples

Embodiment 1

[0050] Get 155g (i.e. 0.72mol) of butyldiethylmalonate, content is 80% NaH 22g, 2,2'-dichloroethyl ether 50g (i.e. 0.35mol), N-methylpyrrolidone 200g, after mixing, in React at 130°C for 50 hours, and neutralize to neutral after the reaction is complete. Remove sodium chloride by filtration, distill under reduced pressure, saponify, acidify, wash, and dry to obtain 52 g of acid, yield 49%;

Embodiment 2

[0052] Get 166g (ie 0.77mol) of dimethyl hexylmalonate, 25g of NaH with a content of 80%, 50g (ie 0.35mol) of 2,2'-dichloroethyl ether, and 200g of N-methylpyrrolidone. ℃ for 50 hours, the reaction is complete and neutralized to neutral. Remove sodium chloride by filtration, distill under reduced pressure, saponify, acidify, wash, and dry to obtain 56 g of acid, yield 45%;

[0053] Gained acid and ammonia are made into ammonium salt, and ethylene glycol solution is made into as electrolyte. In order to illustrate its beneficial effect and traditional ammonium sebacate ethylene glycol electrolyte solution for comparative experiments, its performance comparison is as follows:

[0054] Table I

[0055]

Embodiment 3

[0057] The acid obtained in Example 1 is made into ammonium salt and made into 500g of 5% ethylene glycol solution, put into a 1000ml stainless steel bottle, add 0.1% ammonium hypophosphite, 0.4% p-nitrobenzyl alcohol, seal, and keep the temperature at 105°C Test conductivity after 2000h;

[0058] As a comparison sample, put 500g of 5% ammonium sebacate glycol solution into a 1000ml stainless steel bottle, then add 0.1% ammonium hypophosphite and 0.4% p-nitrobenzyl alcohol, seal it, and test the conductivity at a constant temperature of 105°C for 2000h Rate;

[0059] Table 2: Results comparison table

[0060]

[0061] Combining the data in Table 1 and Table 2 for analysis:

[0062] The acid ammonium salt 5% ethylene glycol solution that embodiment 1 makes is based on making electrolyte, and its flash fire voltage is 36V higher than 5% ammonium sebacate ethylene glycol solution, through 105 ℃, after 2000h constant temperature, conductivity Decline slowly (decrease 27%), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com