Preparation method of 2-butyl ammonium sebate glycol electrolyte solution

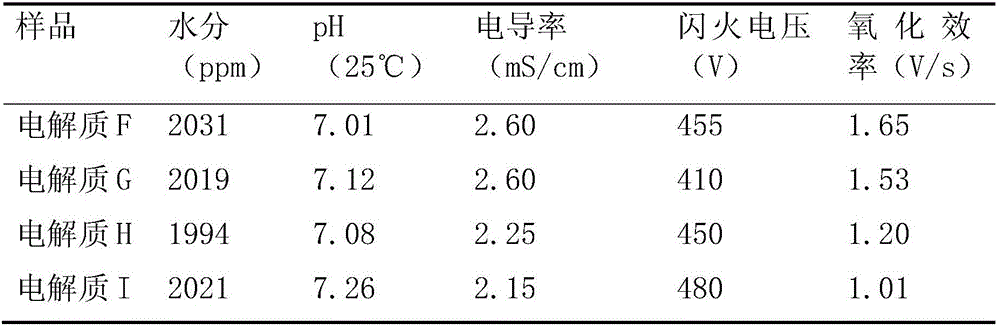

A technology of ammonium sebacate and electrolyte solution, applied in the directions of carboxylate preparation, carboxylate preparation, carboxylate preparation, etc., can solve the problems of increasing refining and purification steps, many steps, easy to retain impurities, etc. The effect of high conductivity, high oxidation efficiency and high flash voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of preparation method of 2-butylammonium sebacate glycol electrolyte solution, this preparation method comprises the steps:

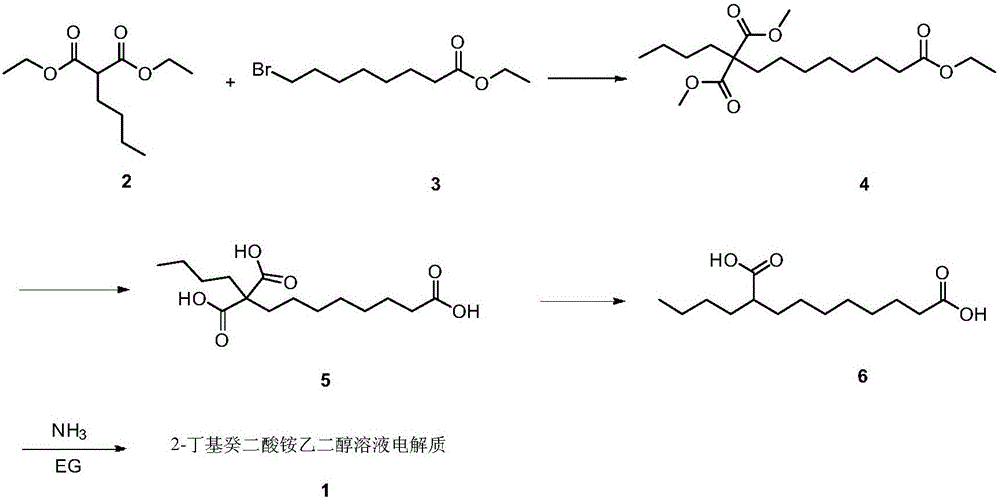

[0024] (1) Preparation of 9,9-bis(methoxycarbonyl)-undecyl carboxylic acid ethyl ester

[0025] Add 1297.6g (6.00mol) of diethyl n-butylmalonate (2) and 1255.8g (5.00mol) of ethyl 8-bromooctanoate (3) into a 10L three-necked flask, add dropwise 20% sodium ethylate ethanol solution 2040.6 g (6.00mol), the temperature is controlled below 60°C, after the dropwise addition is completed, stir under reflux for several hours, use the gas phase to control the reaction end point, concentrate the reaction solution after the raw material (3) is completely reacted, and then add 2L of water to the reaction kettle , extracted with an appropriate amount of ethyl acetate and concentrated, and the concentrated solution was rectified to obtain 1636.5 g of 9,9-bis(methoxycarbonyl)-undecanecarboxylic acid ethyl ester (4), with a purity of 99.1% and a yield of...

Embodiment 2

[0033] A kind of preparation method of 2-butylammonium sebacate glycol electrolyte solution, this preparation method comprises the steps:

[0034] (1) Preparation of 9,9-bis(methoxycarbonyl)-undecyl carboxylic acid ethyl ester

[0035] Add 1081.3g (5.00mol) of diethyl n-butylmalonate (2) and 1255.8g (5.00mol) of ethyl 8-bromooctanoate (3) into a 10L three-necked flask, add dropwise 1350.6 g of 20% sodium methoxide methanol solution g (5.00mol), the temperature is controlled below 60°C, after the dropwise addition is completed, stir under reflux for several hours, use the gas phase to control the reaction end point, concentrate the reaction solution after the raw material (3) is completely reacted, and then add 3L of water to the reaction kettle , extracted with an appropriate amount of ethyl acetate and then concentrated, and the concentrated solution was rectified to obtain 1625.6 g of 9,9-di(methoxycarbonyl)-undecanecarboxylic acid ethyl ester (4), with a purity of 99.0% and...

Embodiment 3

[0043] A kind of preparation method of 2-butyl ammonium sebacate glycol electrolyte solution, it is characterized in that: this preparation method comprises the steps:

[0044] (1) Preparation of 9,9-bis(methoxycarbonyl)-undecyl carboxylic acid ethyl ester

[0045] Add 1340.9g (6.20mol) of diethyl n-butylmalonate (2) and 1255.8g (5.00mol) of ethyl 8-bromooctanoate (3) into a 10L three-necked flask, and dropwise add 20% potassium ethylate ethanol solution 2314.4 g (5.50mol), the temperature is controlled below 60°C, after the dropwise addition is completed, stir under reflux for several hours, use the gas phase to control the reaction end point, concentrate the reaction solution after the raw material (3) is completely reacted, and then add 3L of water to the reaction kettle , extracted with an appropriate amount of ethyl acetate and concentrated, and the concentrated solution was rectified to obtain 1645.5 g of 9,9-bis(methoxycarbonyl)-undecanecarboxylic acid ethyl ester (4), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com