Working electrolytic solution of aluminum electrolytic capacitor with resistance to high voltage and wide-range temperature and manufacturing method thereof

An aluminum electrolytic capacitor and electrolyte technology, which is applied in the field of electrolyte, can solve the problems that cannot well meet the requirements of the use temperature range and withstand voltage of aluminum electrolytic capacitors, the capacitor withstand voltage is unstable, and the capacitor bulges, etc., and achieves good application. Prospect, low cost, good effect of low temperature anti-freezing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018]

[0019] Electrolyte preparation:

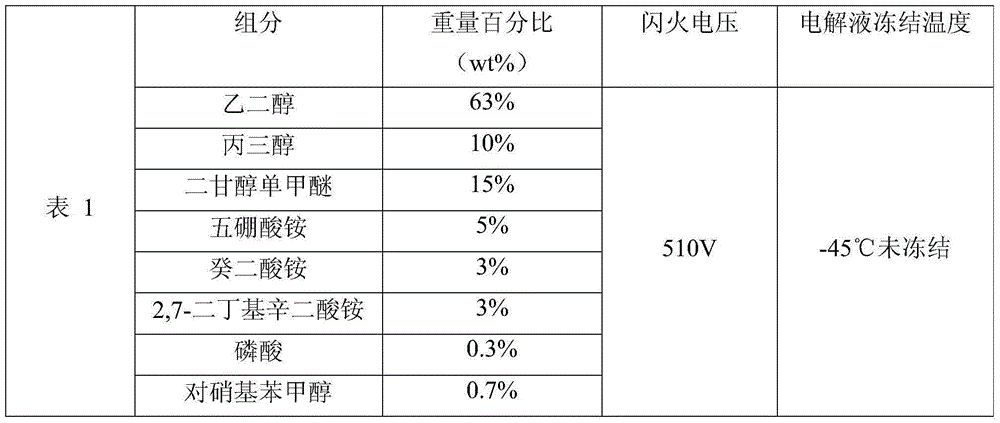

[0020] (1) According to the formula in Table 1, mix and heat ethylene glycol, glycerin, and diethylene glycol monomethyl ether to 60°C; then add ammonium pentaborate, ammonium sebacate, 2,7-dibutyloctane ammonium acid, stir well and heat to 85°C;

[0021] (2) Add phosphoric acid and p-nitrobenzyl alcohol to the above mixed solution, stir and mix evenly, and continue heating to 87° C.; through forced cooling or natural cooling, a working electrolyte for high-voltage and wide-temperature aluminum electrolytic capacitors is obtained.

Embodiment 2

[0023]

[0024] Electrolyte preparation:

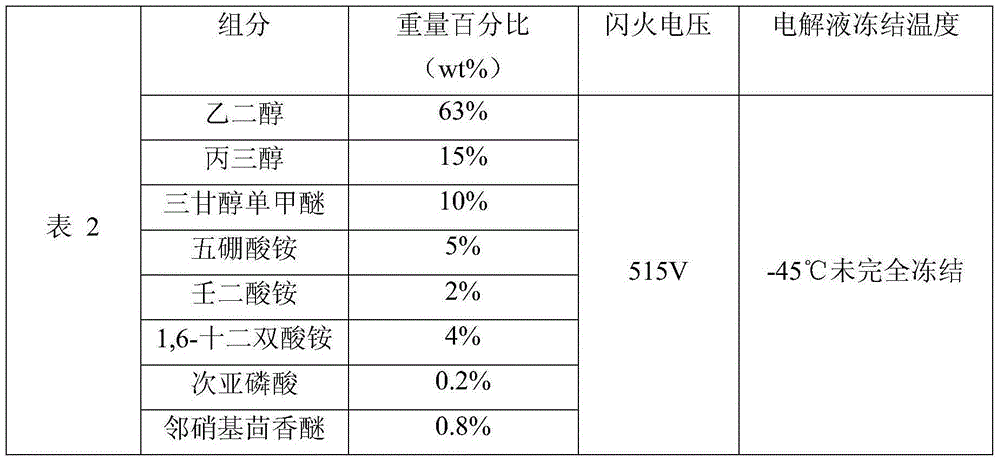

[0025] (1) According to the formula in Table 2, mix and heat ethylene glycol, glycerin, and triethylene glycol monomethyl ether to 60°C; then add ammonium pentaborate, ammonium azelate, and ammonium 1,6-dodecanoate , stir well and heat to 88°C;

[0026] (2) Add the above mixed liquid to hypophosphorous acid and o-nitroanisole, stir and mix evenly, and continue heating to 90° C.; through forced cooling or natural cooling, a working electrolyte for high-voltage and wide-temperature aluminum electrolytic capacitors is obtained.

Embodiment 3

[0028]

[0029] Electrolyte preparation:

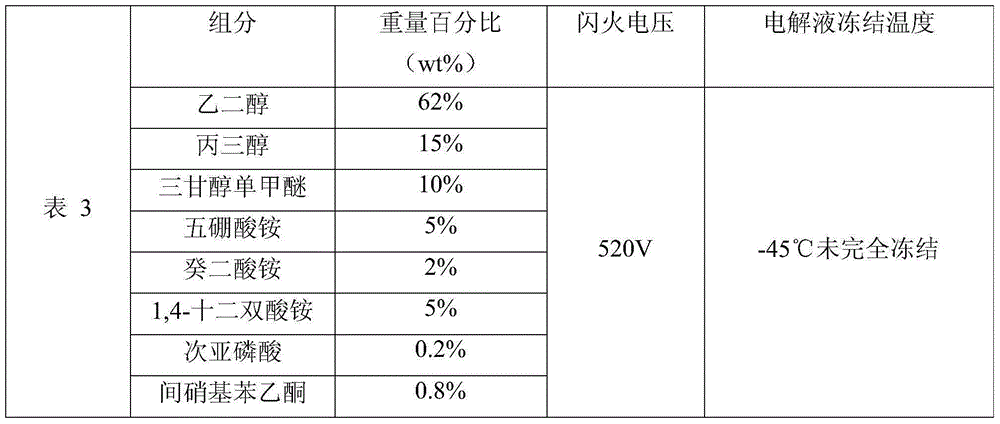

[0030] (1) According to the formula in Table 3, mix and heat ethylene glycol, glycerin, and triethylene glycol monomethyl ether to 80°C; then add ammonium pentaborate, ammonium sebacate, and ammonium 1,4-dodecanoate , fully stirred evenly, and heated to 90°C;

[0031] (2) Add the above mixed liquid to hypophosphorous acid and m-nitroacetophenone, stir and mix evenly, and continue heating to 95°C; through forced cooling or natural cooling, a working electrolyte for high-voltage and wide-temperature aluminum electrolytic capacitors is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com