Electrolyte for driving ultrahigh voltage large-sized aluminium electrolytic capacitor and solute thereof

A technology of aluminum electrolytic capacitors and electrolytes, applied in electrolytic capacitors, capacitors, circuits, etc., can solve problems such as failure, increase in moisture content, and decrease in electrolyte flashover voltage, and achieve high yield and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

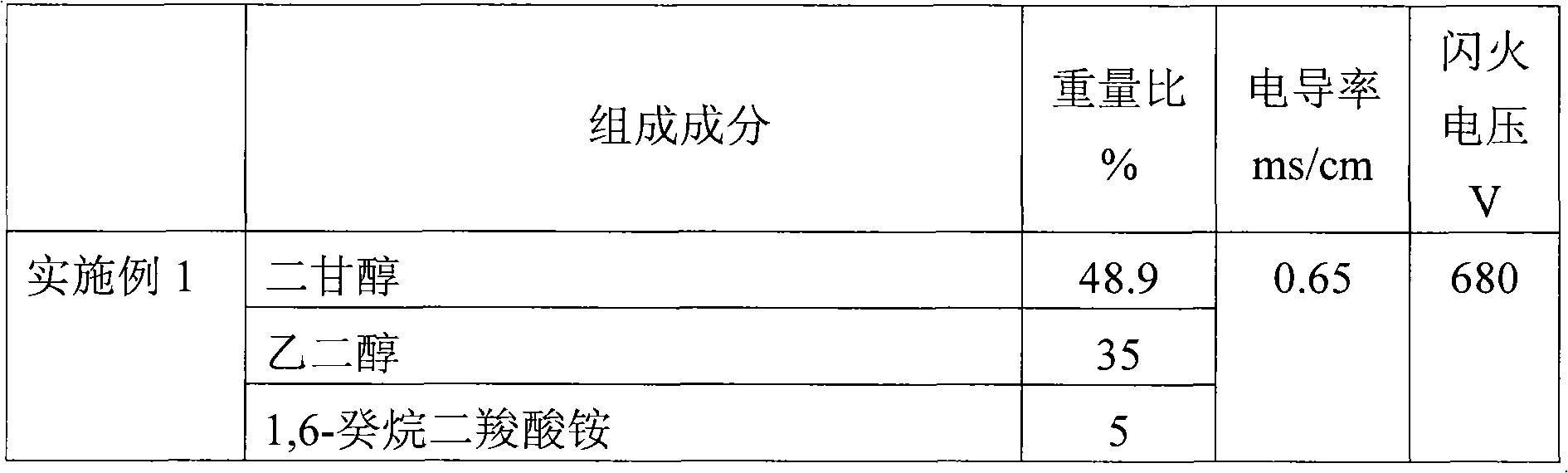

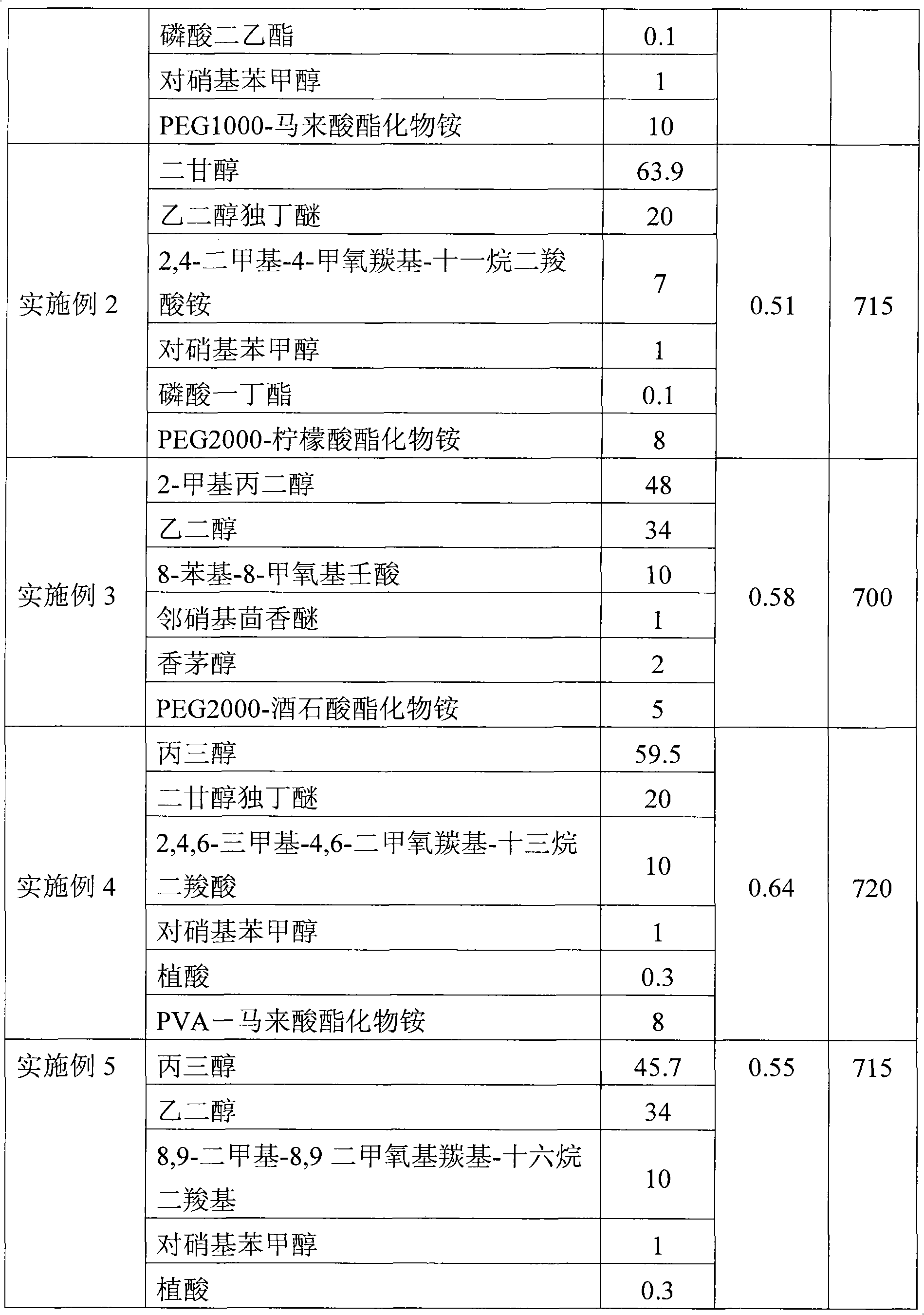

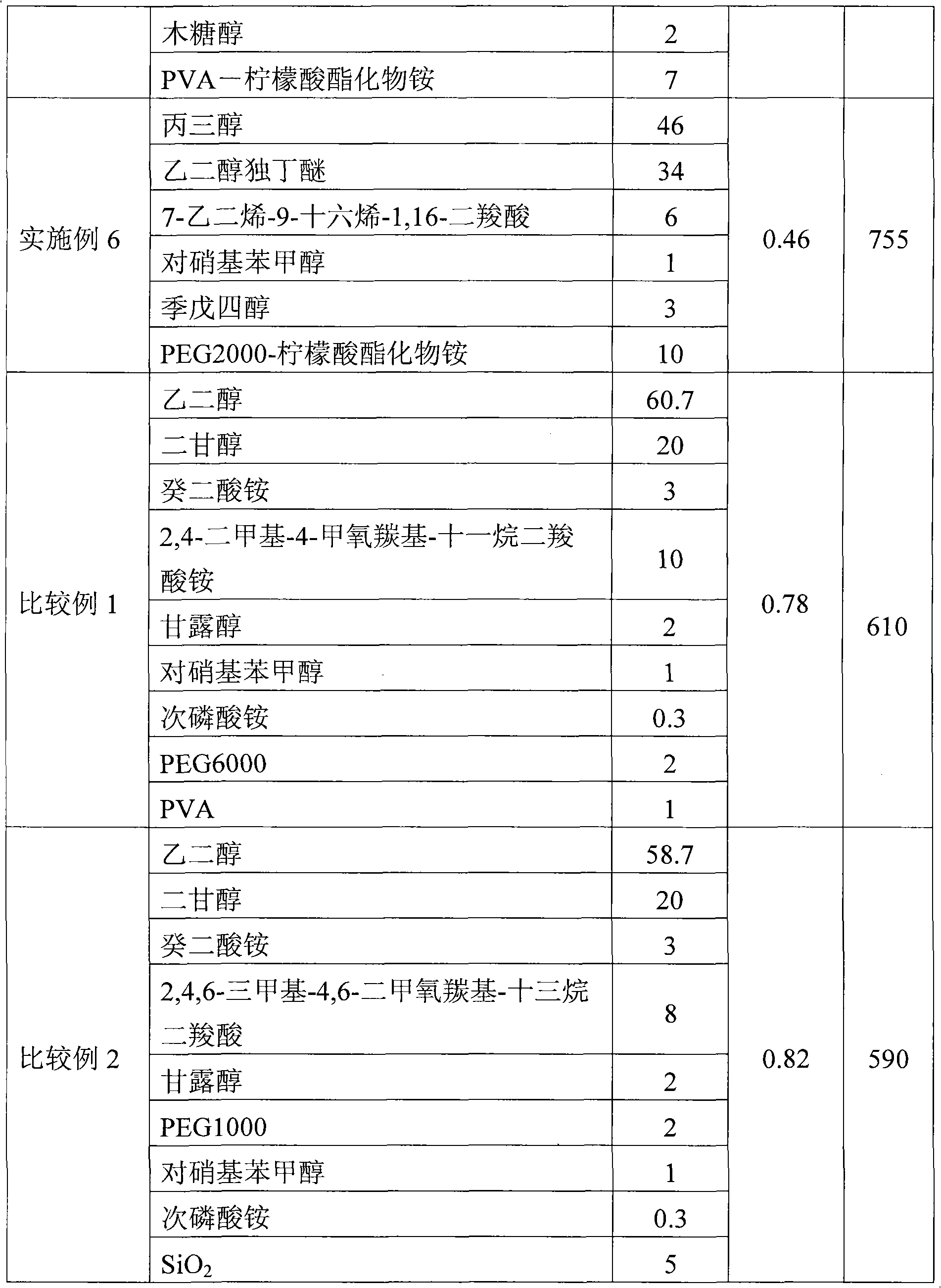

Examples

Embodiment Construction

[0023] The technical principle of the present invention will be described below.

[0024] For aluminum electrolytic capacitors, since the liquid electrolyte is the actual cathode of the aluminum electrolytic capacitor, the conductive carriers of the actual cathode are no longer free electrons but ions. Among them, the flashover voltage of the aluminum electrolytic capacitor is related to the negative ion concentration in the electrolyte The relationship is:

[0025] u B = a-blg[Anion] (1)

[0026] In the formula (1): [Anion] is the negative ion concentration in the electrolyte, and a and b are constants related to the electrolyte.

[0027] It can be seen from the above formula that the concentration and type of negative ions in the electrolyte are related to U B closely related, it mainly affects U from two aspects B . One is that in anodic polarization, negative ions soak into the dielectric film, which will reduce the strength of the dielectric film; secondly, the incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com