Electrolyte of medium-high voltage aluminum electrolytic capacitor and preparation method of solute thereof

A technology for aluminum electrolytic capacitors and electrolytes, which is applied in the field of preparation of electrolytes and their solutes, can solve the problems of affecting the performance and life of capacitors, affecting the life of capacitors, and poor low-temperature performance, achieving good low-temperature performance, high flashover voltage, The effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

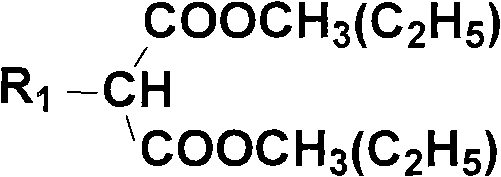

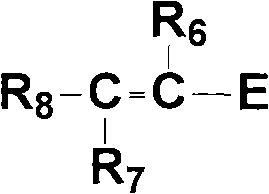

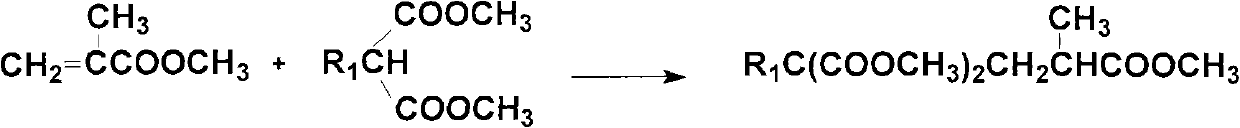

Method used

Image

Examples

Embodiment 1

[0063] Dimethyl hexylmalonate 210g (ie 0.97mol), methyl methacrylate 100g (ie 1mol), sodium methoxide 5g (ie 0.093mol), mix and stir, react at 90°C for 14 hours, neutralize to neutral properties, distillation under reduced pressure, and then saponification, acidification, decarboxylation, and cleaning to obtain 150 g of 2-methyl-4-hexylglutaric acid, with a yield of 67% (calculated as dimethyl hexylmalonate);

Embodiment 2

[0065] 435g (ie 2.3mol) of butyl dimethyl malonate, 250g (ie 2.5mol) of methyl methacrylate, 13.5g (ie 0.25mol) of sodium methoxide, mix and stir, react at 85°C for 10 hours, and Neutralized, distilled under reduced pressure, then saponified, acidified, decarboxylated, and washed to obtain 360 g of 2-methyl-4-butylglutaric acid with a yield of 77% (calculated as dimethyl butylmalonate) ;

Embodiment 3

[0067] Make positive ammonium salt from 2-methyl-4-hexylglutaric acid and ammonia, make 5% ethylene glycol solution as electrolyte, add 0.1% ammonium hypophosphite and 0.4% p-nitrobenzyl alcohol, seal Constant temperature at 105°C in a stainless steel bottle;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com