650V aluminum electrolytic capacitor working electrolyte

A technology for aluminum electrolytic capacitors and electrolytes, applied in electrolytic capacitors, capacitors, circuits, etc., which can solve problems such as no conductance, reduced conductivity of electrolytes, and increased difficulty in impregnating aluminum electrolytic capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Configure the electrolyte according to the formula in Table 1, and use the prepared electrolyte to make 10 aluminum electrolytic capacitors, each of which is used for life test. The specifications of aluminum electrolytic capacitors are: 650V, 1200μF, Φ76*170mm, according to the IEC-60384-4-1-2007 standard test its capacity C (μF), loss Tanδ (%), leakage current I (μA), and load After 5000 hours, test its capacity C (μF), capacity change percentage ΔC (%), loss Tanδ (%), and leakage current I (μA). The load conditions are 85°C, 120Hz, and ripple current 15.8A / piece. The test results are shown in Table 7.

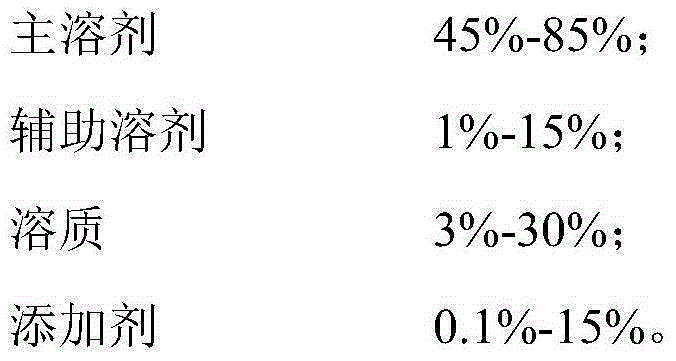

[0031] The formula of table 1 embodiment 1

[0032]

Embodiment 2

[0034] Configure the electrolyte according to the formula in Table 2, and use the prepared electrolyte to make 10 aluminum electrolytic capacitors, each of which is used for life test. Test items and standards are the same as in Example 1. The test results are shown in Table 7.

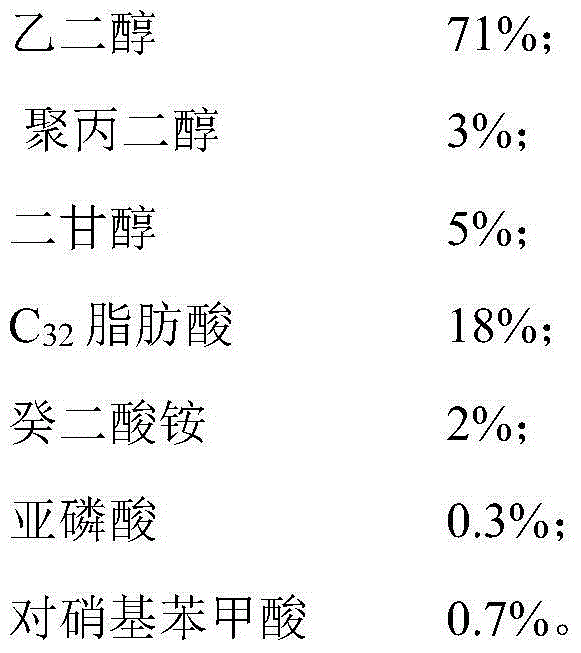

[0035] The formula of table 2 embodiment 2

[0036]

[0037]

Embodiment 3

[0039] Configure the electrolyte according to the formula in Table 3, and use the prepared electrolyte to make 10 aluminum electrolytic capacitors, each of which is used for life test. Test items and standards are the same as in Example 1. The test results are shown in Table 7.

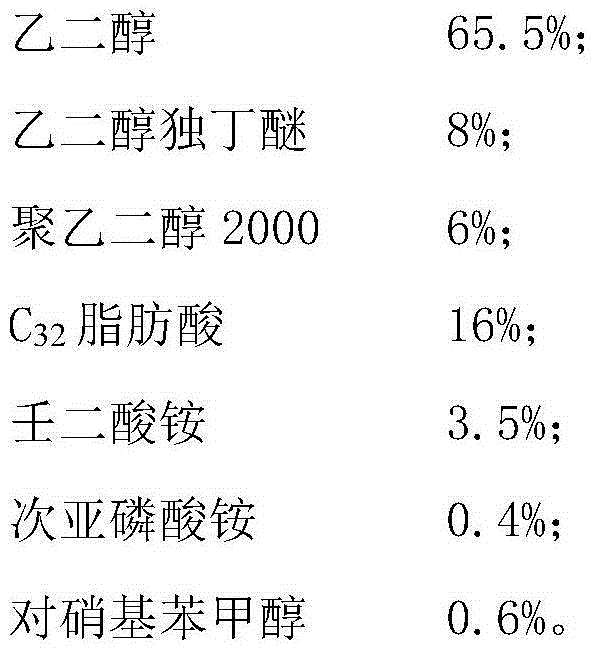

[0040] The formula of table 3 embodiment 3

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com