Electrolyte for aluminum electrolytic capacitor and preparation method of electrolyte

An aluminum electrolytic capacitor and electrolyte technology, applied in the field of capacitors, can solve problems such as flammability and explosion, and achieve the effects of improving flash voltage, improving performance, and stabilizing good characteristic parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also discloses a method for preparing an electrolytic solution for an aluminum electrolytic capacitor, comprising the following steps:

[0033] S1: Fully mix 50%-60% ethylene glycol and 20%-30% diethylene glycol by weight, and add flash voltage booster when heated to 70°C-80°C, stir while adding, wait until After complete dissolution, continue to add 15% to 20% of solute and continue to heat up to 120°C to 130°C, stirring until completely dissolved;

[0034] S2: Continue to raise the temperature of the mixture in S1 to 135°C~150°C, and add 0.1%~5% oxide film stabilizer, 0.1%~3% hydrogen absorbing agent and 0.5%~3% surface active Add the agent and keep stirring until it is completely dissolved;

[0035] S3: Cool the mixed solution in step S2 to 80° C. to 85° C., add 5% to 10% by weight of a flame retardant, and naturally cool to normal temperature.

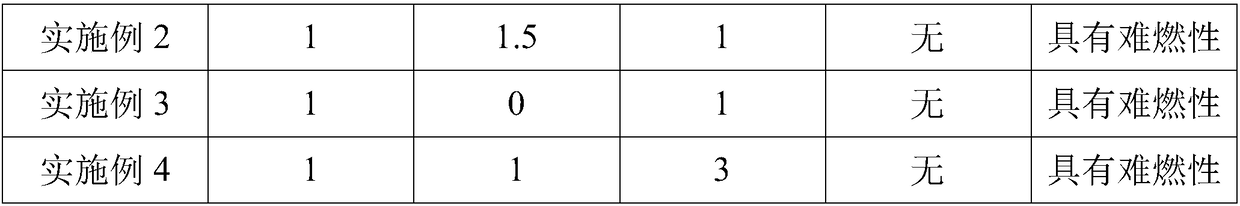

[0036] In the technical solution of the present invention, five embodiments are obtained according...

Embodiment 1

[0037] Embodiment 1: an electrolytic solution for aluminum electrolytic capacitors, comprising 15% by weight of boric acid, 0.3% of phosphorous acid, 0.2% of nitrophenol, 2.5% of ammonium benzoate and polyethylene glycol 400 mixed solution, 5% Alkyl Phosphate, 55% Ethylene Glycol and 22% Diethylene Glycol.

Embodiment 2

[0038] Embodiment 2: An electrolytic solution for aluminum electrolytic capacitors, comprising 15% by weight of boric acid, 0.3% of phosphorous acid, 2% of modified polyvinyl alcohol, 0.2% of nitrophenol, and 2.5% of ammonium benzoate Mixture with polyethylene glycol 400, 5% alkyl phosphate, 55% ethylene glycol and 20% diethylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com