Method for environment-friendly clean production of D,L-methionine

A clean production and methionine technology, applied in the chemical industry, can solve problems such as energy waste and cycle problems, and achieve the effects of low cost, simple operation, and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 3484.4 grams of 5-(2-methylthioethyl)-hydantoin aqueous solution and add it to the autoclave, wherein 5-(2-methylthioethyl)-hydantoin 696.88 grams (4mol) , then add 1658.4 grams of potassium carbonate aqueous solution with a mass fraction of 50%, close the autoclave, immediately raise the temperature to 180 ° C, keep the temperature for 20 minutes, and then release the pressure to normal pressure. The residual ammonia is less than 50ppm; carbon dioxide is passed into the saponified liquid after deammonification, the pressure of carbon dioxide is 0.5MPa, the neutralization temperature is 20°C, and the pH at the neutralization end point is 6.8, the crystals are suction filtered, washed with a small amount of water, and obtained The wet product of methionine is dried to obtain 415.9 grams of methionine product with a content of 99.3%; the washing water is combined with the mother liquor of suction filtration to obtain 3659.44 grams of potassium bicarbonate aqueous solu...

Embodiment 2

[0036] Take 3484.4 grams of 5-(2-methylthioethyl)-hydantoin aqueous solution and add it to the autoclave, wherein 5-(2-methylthioethyl)-hydantoin 696.88 grams (4mol) , then add 1474.13 grams of potassium carbonate aqueous solution with a mass fraction of 60%, close the autoclave, immediately heat up to 185 ° C, keep the temperature for 15 minutes, and then release the pressure to normal pressure. The residual ammonia is less than 40ppm; carbon dioxide is passed into the saponified liquid after deammonification, the pressure of carbon dioxide is 0.8MPa, the neutralization temperature is 15°C, and the pH at the neutralization end point is 6.0, the crystals are filtered by suction, washed with a small amount of water, and obtained The wet product of methionine is dried to obtain 445.65 grams of methionine product with a content of 99.3%; the washing water is combined with the mother liquor of suction filtration to obtain 3725 grams of potassium bicarbonate aqueous solution contain...

Embodiment 3

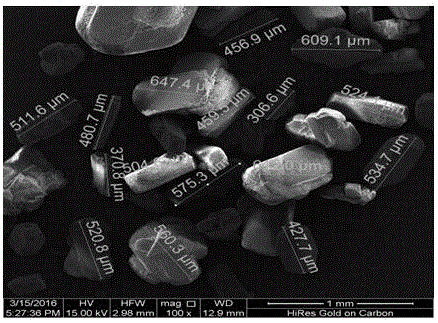

[0041] Take 3484.4 grams of 5-(2-methylthioethyl)-hydantoin aqueous solution and add it to the autoclave, wherein 5-(2-methylthioethyl)-hydantoin 696.88 grams (4mol) , then add 1474.13 grams of potassium carbonate aqueous solution with a mass fraction of 60%, close the autoclave, immediately heat up to 185 ° C, keep the temperature for 15 minutes, and then release the pressure to normal pressure. The residual ammonia of ammonia is less than 40ppm; carbon dioxide is introduced into the saponified liquid after deamination, the pressure of carbon dioxide is 0.8MPa, the neutralization temperature is 15°C, the pH of the neutralization end point is 6.0, and the crystals are filtered by suction to obtain the wet product of methionine , the obtained wet product is recrystallized, the crystals are suction filtered, and dried to obtain 312.0 grams of methionine product with a content of 99.6%. The obtained methionine product is analyzed by scanning electron microscope, as shown in figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com