Method for preparing water-soluble monascus yellow pigment

A technology for monascus yellow pigment and monascus red pigment, which is applied in the field of preparation of water-soluble monascus yellow pigment, can solve the problems of introducing harmful substances and high production costs, and achieves the effects of easy product, low price and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

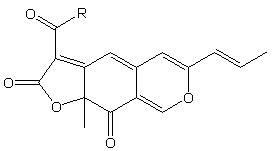

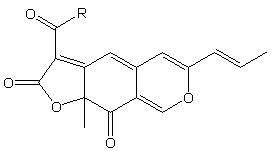

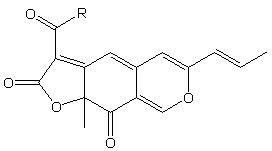

Image

Examples

Embodiment 1

[0025] Weigh 1.0g of alcohol-soluble monascus red pigment powder, add 10ml of concentrated sulfuric acid, stir evenly, and react at 15°C under normal pressure for 4 hours. h, centrifuge, collect the precipitate, wash the precipitate with water to pH4~pH5, and then centrifuge to remove free water to obtain the precipitate; add 0.25g of sodium hydroxide to the precipitate for alkaline hydrolysis, the reaction temperature is 20°C, and the reaction time is 1h; After the alkaline hydrolysis, adjust the solution to pH4.0-pH6.0 with 1mol / L hydrochloric acid solution; concentrate, dry and pulverize, and the obtained dry powder is the prepared water-soluble monascus yellow pigment.

Embodiment 2

[0027] Weigh 1.0g of alcohol-soluble monascus red pigment powder, add 5ml of fuming sulfuric acid, stir evenly, and react under normal pressure at 25°C for 2 hours. After the reaction, add appropriate amount of water to the reaction solution, stir evenly, and let stand Centrifuge for 1h, collect the precipitate, wash the precipitate with water to pH4~pH5, and then centrifuge to remove free water to obtain the precipitate; add 0.30g of sodium carbonate to the precipitate for alkaline hydrolysis, the reaction temperature is 30°C, and the reaction time is 3h; alkali After the solution is finished, adjust the solution to pH 4.0-pH 6.0 with 2 mol / L citric acid solution; concentrate, dry and pulverize, and the obtained dry powder is the prepared water-soluble monascus yellow pigment.

Embodiment 3

[0029] Weigh 1.0g of alcohol-soluble monascus red pigment powder, add 10ml of chlorosulfonic acid, stir evenly, and react at 30°C under normal pressure for 0.5 hours. After the reaction, add an appropriate amount of water to the reaction solution, stir evenly, and let stand 2h, centrifuge, collect the precipitate, wash the precipitate with water to pH4~pH5, and then centrifuge to remove free water to obtain the precipitate; add 0.50g sodium bicarbonate to the precipitate for alkaline hydrolysis, the reaction temperature is 40°C, and the reaction time is 3h; After the alkaline hydrolysis, adjust the solution to pH 4.0-pH 6.0 with 2mol / L acetic acid solution; concentrate, dry and pulverize, and the obtained dry powder is the prepared water-soluble monascus yellow pigment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com