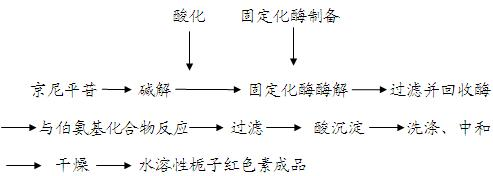

Method for preparing gardenia red pigment by using immobilized enzyme

A technology of immobilizing enzymes and gardenia red, applied in the directions of immobilization on/in organic carriers, fermentation, etc., can solve the problems of difficult separation and recovery of enzyme liquid, complicated purification and enrichment process, low product color and price, etc. The effect of saving resources, low price and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Preparation of immobilized enzyme

[0054] Mix 30g of sodium alginate with 20g of gelatin, add it to 1L of water, stir to dissolve at 40℃, add 40g of cellulase, stir and mix well, shake at 40℃ constant temperature shaker, 100r / min for 0.5h, Then the mixture was poured dropwise into 1.5mol / L calcium chloride solution, and allowed to stand for 60min at 4℃ to make it agglomerate and solidify, collect the gel pellets, and use 0.2mol / L sodium chloride solution Washing, suction filtration to remove free water, collecting gel pellets to obtain immobilized enzyme.

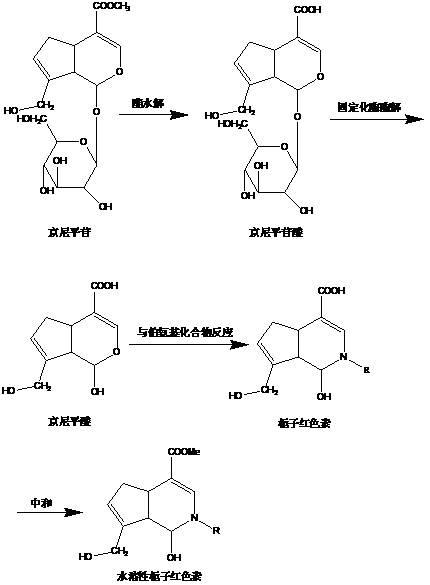

[0055] (2) Preparation of gardenia red pigment

[0056] Weigh 0.5Kg of geniposide powder and dissolve it in 3L of sodium hydroxide solution with a concentration of 4mol / L, and react on a shaker at 55°C for 8 hours. After the reaction is over, adjust the reaction solution with 5mol / L citric acid solution to pH4.5, add immobilized cellulase with a wet weight of 100g, hydrolyze at 50°C for 12 hours, filter, recover th...

Embodiment 2

[0058] (1) Preparation of immobilized enzyme

[0059] Mix 4g of sodium alginate solution with 2g of modified starch, add to 100ml of water, stir to dissolve at 40°C, add 2g of β-glucosidase, stir and mix well, place it on a constant temperature shaker at 37°C, 50r / Min shake for 1h, then inject the mixture dropwise into a 2.0mol / L calcium chloride solution, and let it stand for 120min at 4℃ to make it agglomerate and solidify. Collect the gel pellets and use 0.2mol / L Wash with sodium chloride solution, remove free water by suction filtration, collect gel pellets to obtain immobilized enzyme.

[0060] (2) Preparation of gardenia red pigment

[0061] Weigh 15g of geniposide powder and dissolve it in 90ml of 3.5mol / L sodium hydroxide solution, and react on a shaker at 50°C for 12 hours. After the reaction, adjust the reaction solution to pH4.5, add immobilized β-glucosidase with a wet weight of 5g, enzymolyze at 50℃ for 8 hours, filter, recover the immobilized enzyme, add 8g sodium ...

Embodiment 3

[0063] (1) Preparation of immobilized enzyme

[0064] Add 100g of sodium alginate to 8L of water, stir to dissolve at 38°C, add 50g of pectinase, stir and mix well, shake on a constant temperature shaker at 37°C at 80r / min for 0.6h, and inject the mixture dropwise In a 2.0mol / L calcium chloride solution, let stand for 100min at 3℃ to make it agglomerate and solidify, collect the gel pellets, wash with 0.15mol / L sodium chloride solution, remove free water by suction and collect The gel beads obtain immobilized enzymes.

[0065] (2) Preparation of gardenia red pigment

[0066] Weigh 1Kg of geniposide powder and dissolve it in 4L of sodium carbonate solution with a concentration of 5mol / L, and react on a shaker at 60℃ for 12 hours. After the reaction, adjust the reaction solution to pH 4.7 with 5mol / L acetic acid solution Add the immobilized pectinase with a wet weight of 150g, hydrolyze the enzyme at 50°C for 12 hours and filter, recover the immobilized enzyme, add 0.8Kg of glycine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com