Glass laminate, display panel with support, method for producing glass laminate and method for manufacturing display panel with support

A technology of display device and manufacturing method, applied in the direction of glass/slag layered products, identification devices, chemical instruments and methods, etc., which can solve the problems of obvious tiny scratches, increased deflection, and inability to handle the production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

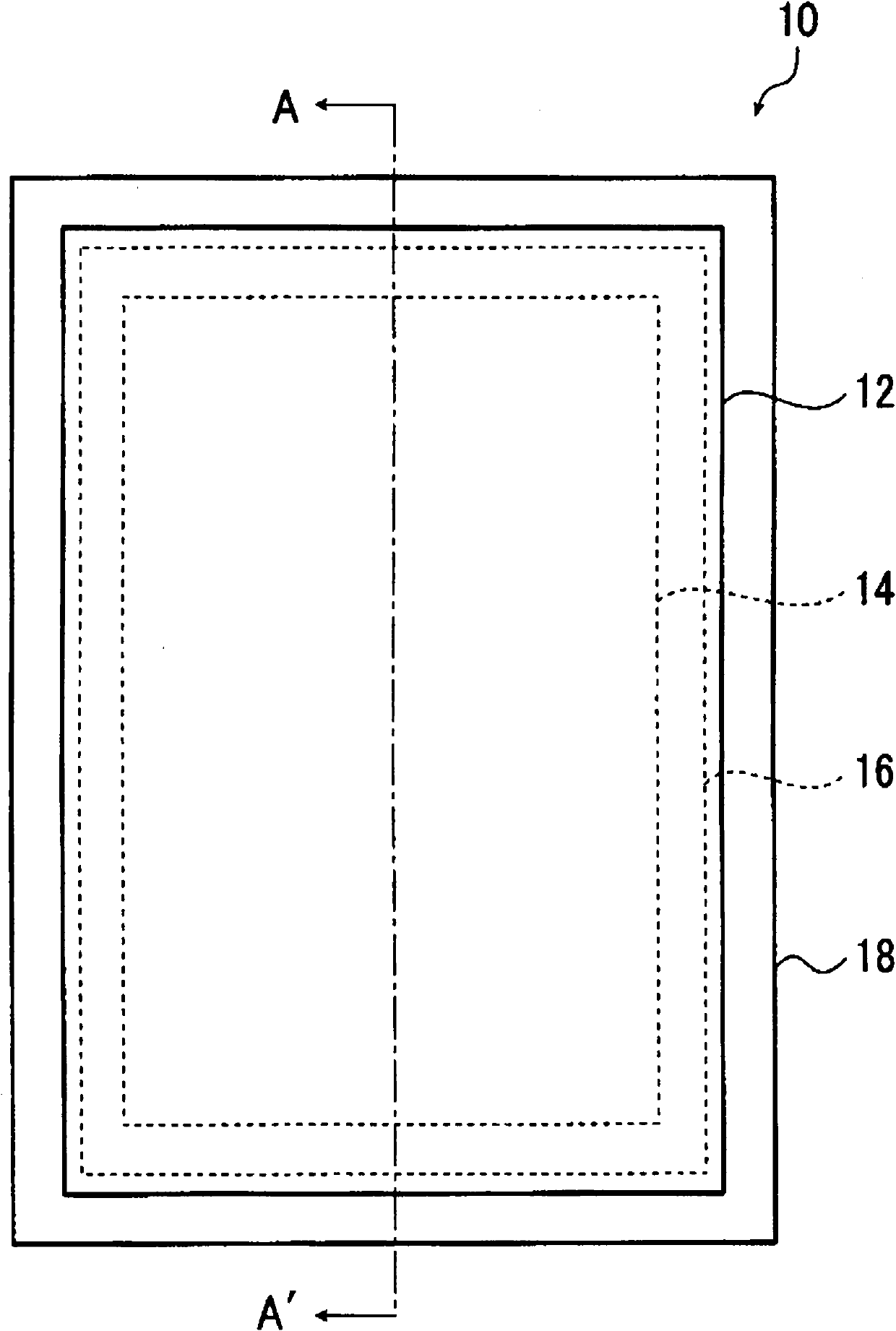

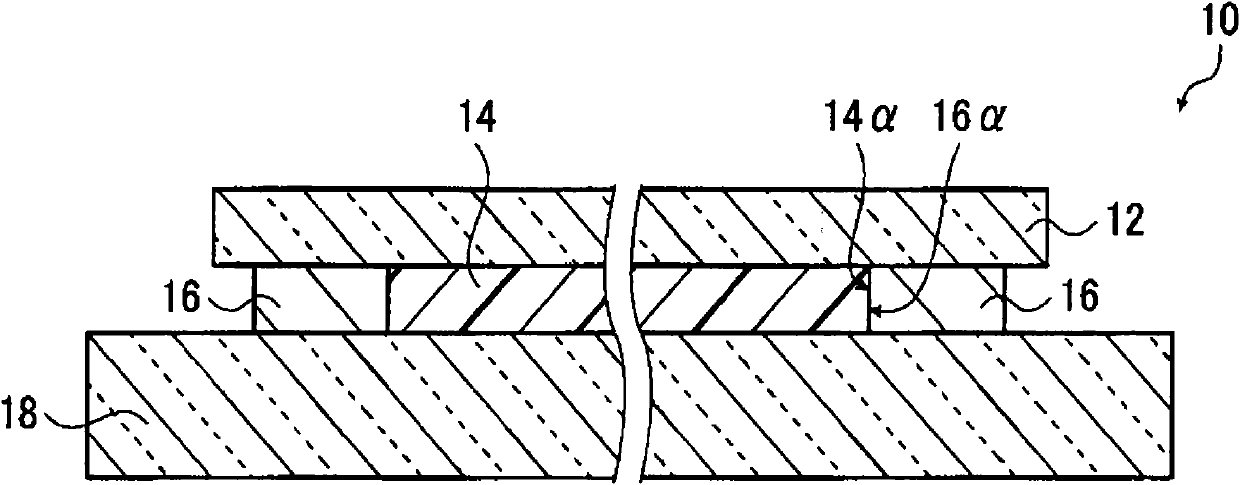

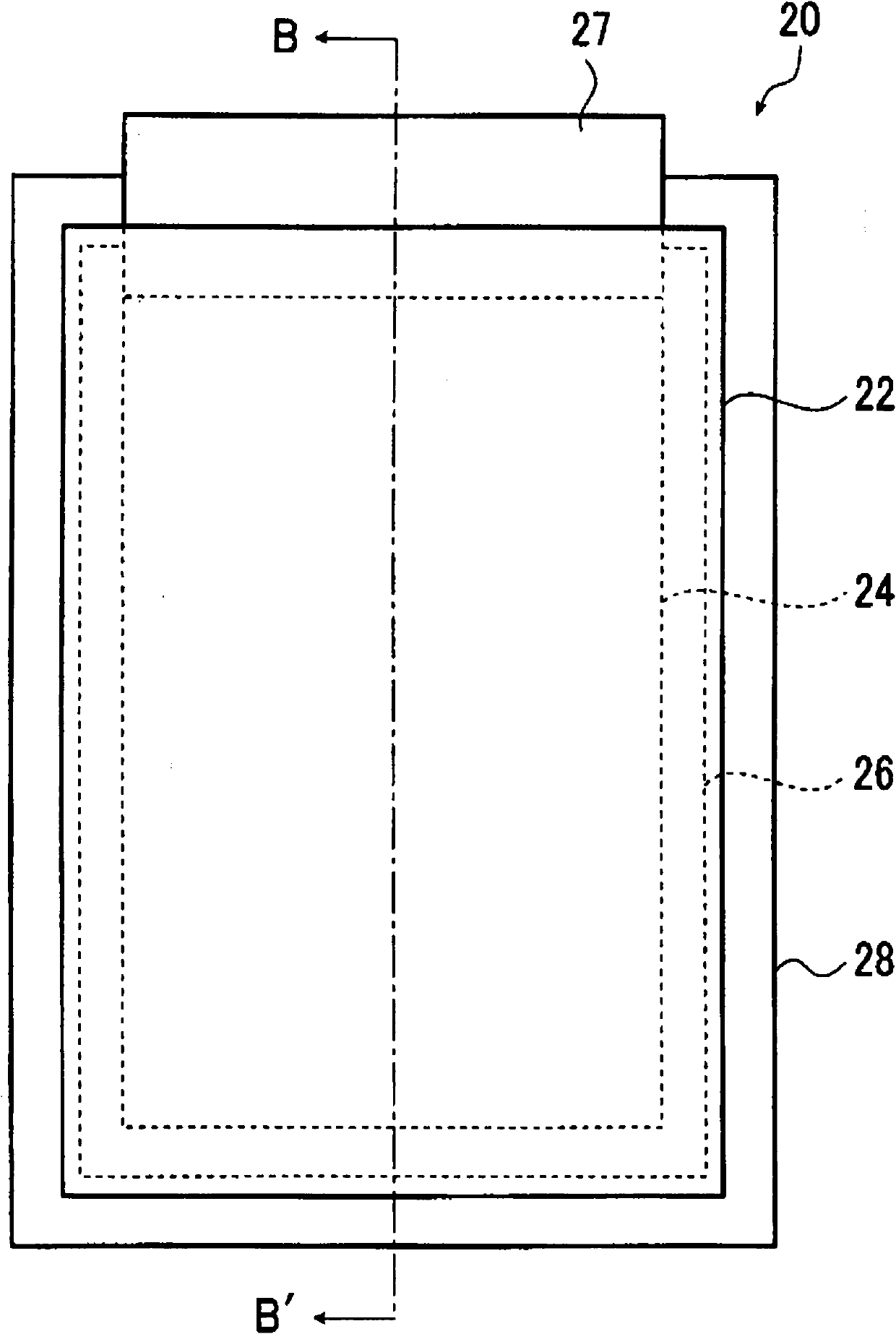

[0262] Manufactured and used with the above by the following method figure 1 , figure 2 The glass laminate of Embodiment 1 described above is basically the same glass laminate. The only difference from Embodiment 1 is the size of the thin glass substrate and the supporting glass substrate. In the glass laminate of Embodiment 1, the main surface area of the thin glass substrate 12 is smaller than that of the supporting glass substrate 18 , but in the glass laminate produced in Example 1, both glass substrates have the same size.

[0263] First, for a length of 720mm, a width of 600mm, a plate thickness of 0.4mm, and a linear expansion coefficient of 38×10 -7 The surface of the supporting glass substrate (manufactured by Asahi Glass Co., Ltd., AN100) at / °C was cleaned with pure water and UV.

[0264]Then, 100 parts by mass of silicone for solvent-free addition reaction release paper (manufactured by Shin-Etsu Silicone Co., Ltd., KNS-320A (viscosity: 0.40 Pa·s)) and a plat...

Embodiment 2

[0277] Use thermoplastic polyimide resin (manufactured by Mitsui Chemicals, AURUM PLC450C) (5% by mass thermal weight loss temperature = 570 ° C), melt it, and form the outer frame layer by extrusion dispensing method, except that it is the same as the embodiment 1 in the same manner to manufacture two glass laminates. And "glass laminated body B-1" which was not heat-processed, and "glass laminated body B-2" which heat-processed were obtained similarly to the case of Example 1. In addition, independently under high vacuum (1.0×10 -5 Pa) Although the temperature of the glass laminate B was raised from room temperature to 450° C., no gas was generated from the glass laminate B. In the obtained glass laminated body B-1 and glass laminated body B-2, the thin glass substrate and the silicone resin adhered without air bubbles, had no convex defects, and had good smoothness.

[0278] In addition, when the above-mentioned peeling test 1 was performed on each of the glass laminated ...

Embodiment 3

[0280] Example 3 is the same as Example 1, but differs in the type, size, thickness, etc. of the supporting glass substrate, resin layer, outer frame layer, and thin glass substrate.

[0281] As a supporting glass substrate, use a length of 720mm, a width of 600mm, a thickness of 0.6mm, and a linear expansion coefficient of 38×10 -7 / °C glass substrate (manufactured by Asahi Glass Co., Ltd., AN100).

[0282] In addition, as the resin for forming the resin layer, a linear polyorganosiloxane having vinyl groups at both ends (manufactured by Arakawa Chemical Industry Co., Ltd., trade name: 8500) and a methyl group having a hydrosilyl group in the molecule were used. Hydrogen polysiloxane (manufactured by Arakawa Chemical Industry Co., Ltd., trade name: 12031). And, it was mixed with a platinum-based catalyst (manufactured by Arakawa Chemical Industry Co., Ltd., trade name: CAT12070) to prepare a mixture, and was coated with a size of 700 mm in length and 580 mm in width by a scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com