Magnetic orientation device, manufacture device and manufacture method of magnetic pigment printed product

A technology for manufacturing a device and a magnetic pigment, which is applied in the field of magnetic orientation devices for magnetic pigment prints, can solve problems such as poor three-dimensional effect, and achieve the effect of improving the three-dimensional effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

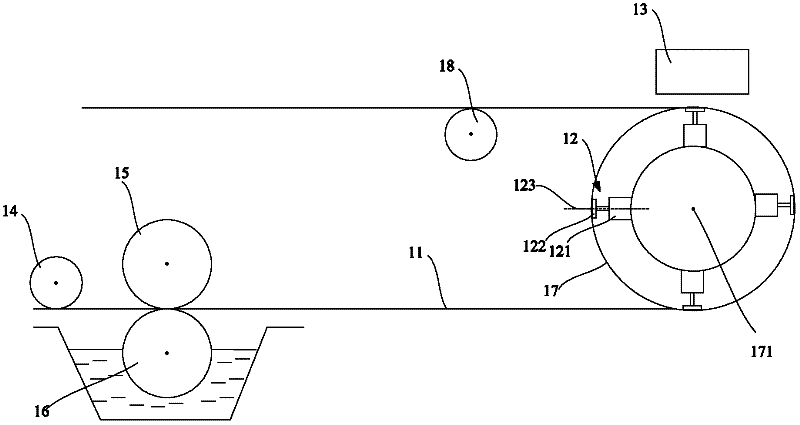

[0026] See figure 1 , figure 1 is a schematic diagram of a manufacturing apparatus for a magnetic pigment print according to a first embodiment of the present invention. The manufacturing device of the magnetic pigment printed matter in this embodiment is a drum-type continuous printing device. Wherein, the printed matter substrate 11 is driven in a predetermined direction under the action of the tension wheels 14 and 18 rotating around their respective rotation axes, the roller 17 or other transmission devices. The printed matter substrate 11 may be paper, film or other flexible material. Inking rollers 15 , 16 print magnetic ink (not shown) on the surface of print substrate 11 . The magnetic ink contains magnetic pigment flakes (not shown) that can be oriented along the direction of the magnetic field, such as magnetic optically variable pigment flakes.

[0027] The printed matter substrate 11 with magnetic ink printed on its surface is transferred onto a cylinder 17 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com