Flexographic printing water-based ink for food packaging

A technology of flexographic printing and water-based ink, applied in the direction of ink, household utensils, applications, etc., to achieve the effects of improved safety performance, strong adhesion, and good migration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1 Cyan ink formulation for flexographic printing

[0048]

[0049]

[0050] 2 Configuration method, detection content and results

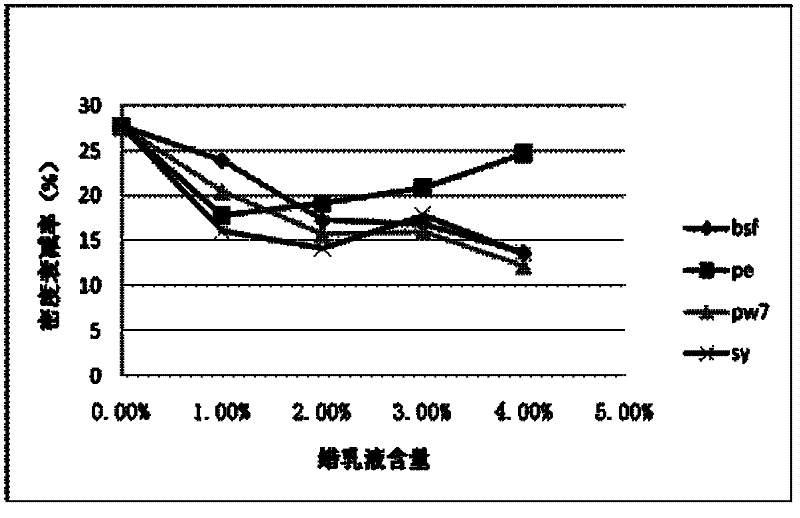

[0051] (1) Weigh each component in proportion, mix and stir for 15 minutes at high speed with a magnetic stirrer or an electric stirrer to obtain a pre-dispersed color paste.

[0052] (2) Pour the color paste into a fast sand mill, add 200 g of medium-sized zirconia beads, and sand at a speed of 2000 r / min for 2.5 to 3.5 hours to obtain evenly dispersed water-based ink.

[0053] (3) Add ethanol (≤8%), isopropanol (≤5%), glycerin (≤6%), etc. to improve the film-forming properties of the ink; use thickener PVP (≤3%) and water (≤10%) ), polyacrylic acid emulsion (≤15%) to adjust the viscosity.

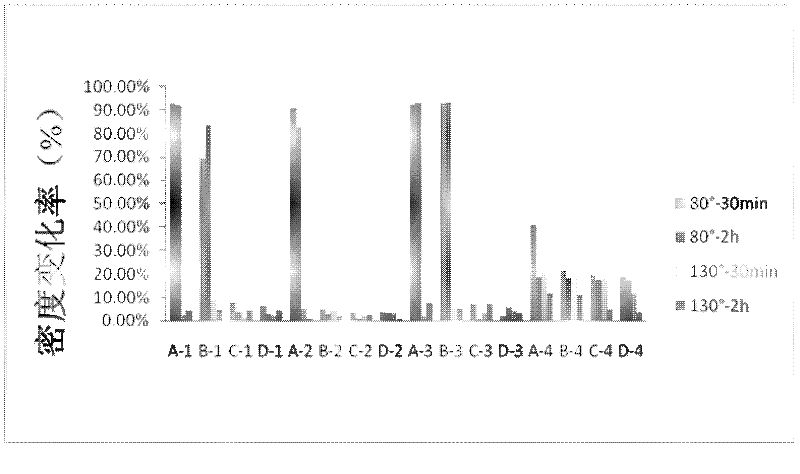

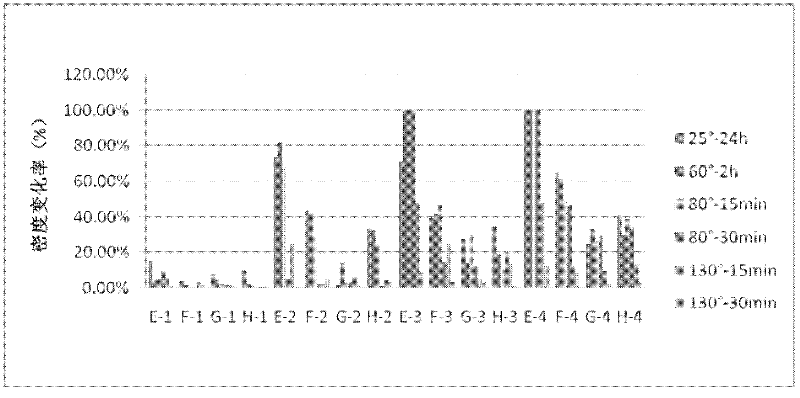

[0054] (4) Use the IGT printability tester (F1 in the Netherlands) to make flexible proofing at 128g / m 2 The coated paper has a density of 1.53 and Lab values of 49.3, -38.4, and -49 when measured with an x·rite500 series densitometer. GB / T...

Embodiment 2

[0061] 1 Ink formulations for flexographic printing

[0062]

[0063] 2 Configuration method, detection content and results

[0064] (1) Use a balance to weigh each component in proportion, and after mixing, stir at a high speed for 15 minutes with a magnetic stirrer or an electric stirrer to obtain a pre-dispersed color paste.

[0065] (2) Pour the color paste into a fast sand mill, add 200g of medium-sized zirconia beads, and sand at a speed of 2000r / min for 2-3 hours to obtain a uniformly dispersed water-based ink.

[0066] (3) Add ethanol (≤8%), isopropanol (≤5%), glycerin (≤5%), etc. to improve the film-forming properties of the ink; use thickener PVP (≤2%) and water (≤10%) ), polyacrylic acid emulsion (≤15%) to adjust the viscosity.

[0067] (4) Use the F1 type printability tester (IGT company in the Netherlands) to do flexible proofing at 128g / m 2 Coated paper, the density measured by x·rite500 series densitometer is 0.9 and the Lab value is 53.6, 46.6, -2.1 respe...

Embodiment 3

[0074] 1 Yellow ink formulation for flexographic printing

[0075]

[0076] 2 Configuration method, detection content and results

[0077] (1) Use a balance to weigh each component in proportion, and after mixing, stir at a high speed for 15 minutes with a magnetic stirrer or an electric stirrer to obtain a pre-dispersed color paste.

[0078] (2) Pour the color paste into a fast sand mill, add 200g of medium-sized zirconia beads, and sand at a speed of 2000r / min for 2-3 hours to obtain a uniformly dispersed water-based ink.

[0079] (3) Add ethanol (≤5%), isopropanol (≤5%), glycerin (≤2%), etc. to improve the film-forming properties of the ink; use thickener PVP (≤2%) and water (≤10%) ), polyacrylic acid emulsion (≤15%) to adjust the viscosity.

[0080] (4) Use the IGT printability tester (F1 in the Netherlands) to make flexible proofing at 128g / m 2 Light ketone paper, measured with an x·rite500 series densitometer, has a density of 0.9 and a Lab value of 88.3, 0.4, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com