Concrete microscopic three-phase structure visualization method based on 3D printing technology

A 3D printing and concrete technology, which is applied in the field of visualization of the meso-three-phase structure of concrete materials, can solve problems such as limitations, difficulties in printing complex multi-material integrated products, and failure to realize 3D model substantiation, achieving important scientific research and The value of engineering practice, the effect of efficient printing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in detail below in conjunction with examples, but those skilled in the art will understand that the following examples are only used to illustrate the present invention, and should not be considered as limiting the scope of the present invention.

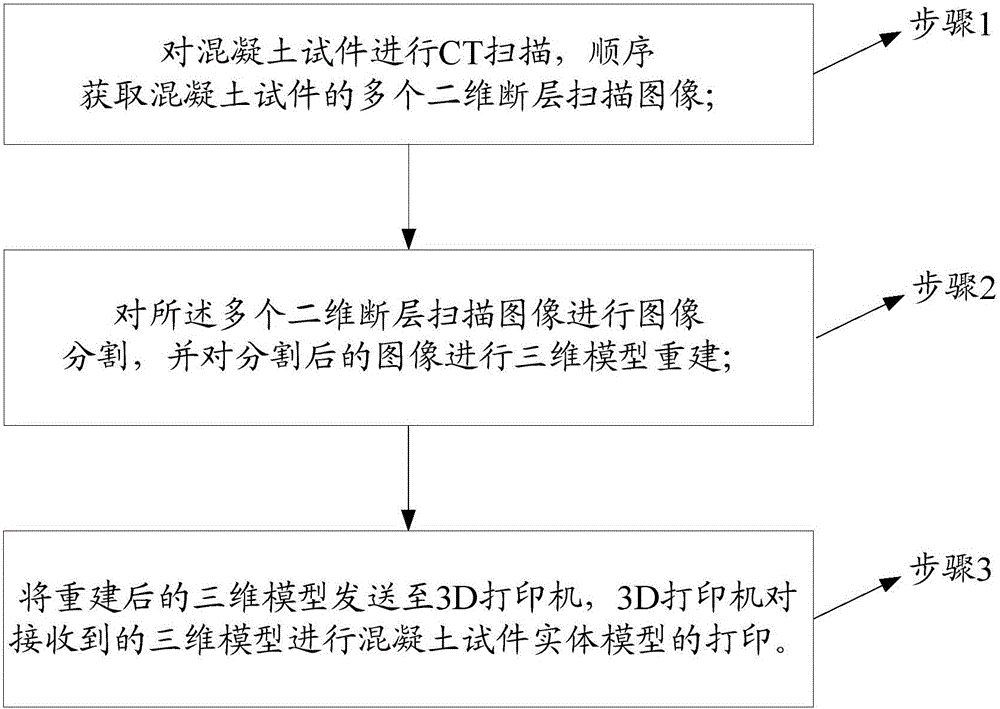

[0030] refer to figure 1 , an embodiment of the present invention provides a method for visualizing the mesoscopic three-phase structure of concrete materials based on 3D printing technology, which is characterized in that it includes the following steps:

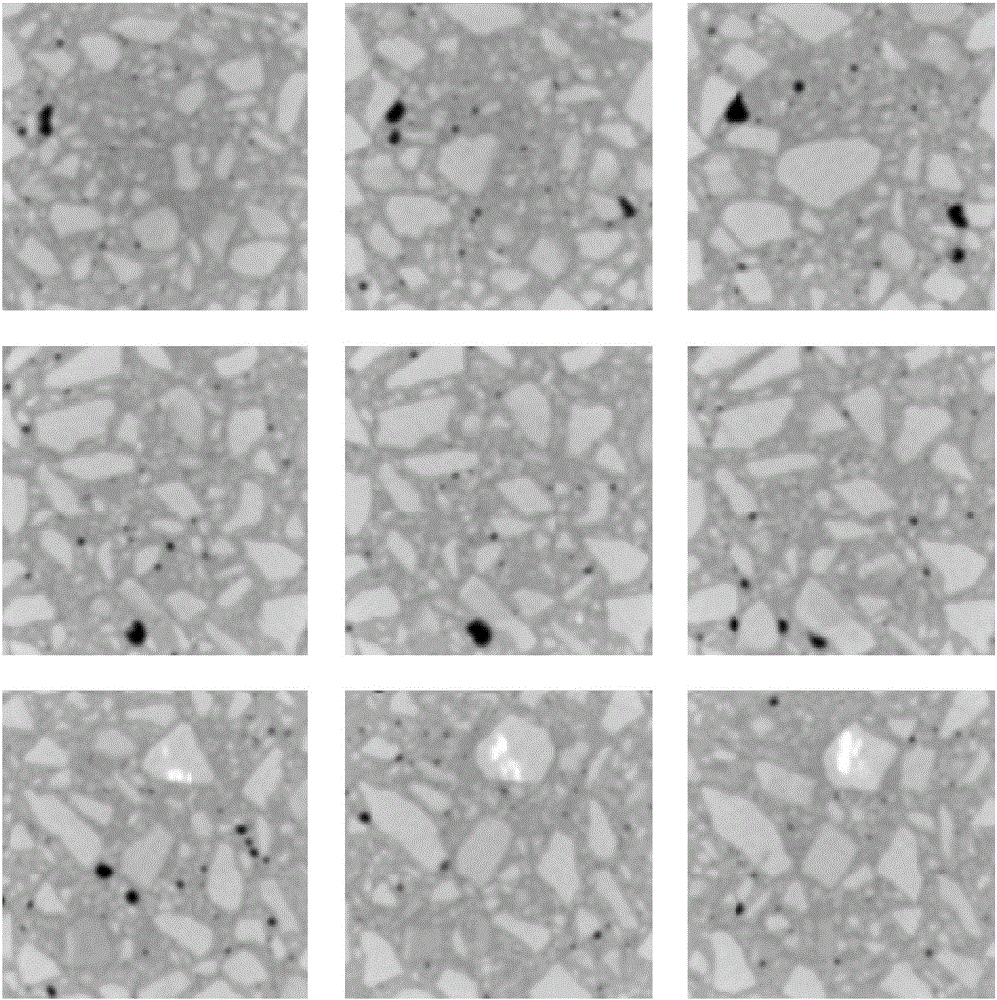

[0031] Step 1, performing CT scanning on the concrete specimen, and sequentially acquiring two-dimensional tomographic images of multiple concrete specimens;

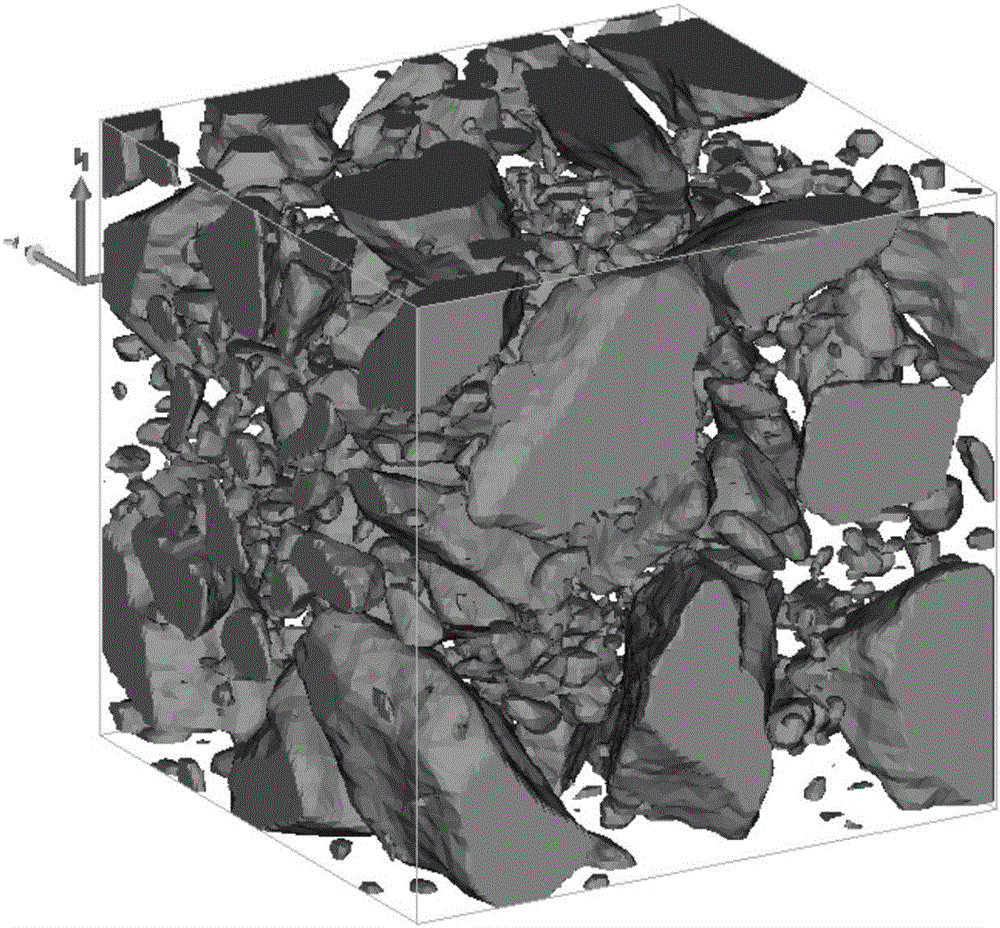

[0032] Step 2, performing image segmentation on the plurality of two-dimensional tomographic images, and performing three-dimensional structural model reconstruction on the segmented images;

[0033] Step 2 contains the following sub-steps:

[0034] Step 2a, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com