3D printing method and device, storage medium and 3D printing system

A 3D printing and storage medium technology, applied in the field of 3D printing, can solve the problems of single resolution, improve the quality of 3D printing, limit the printing accuracy of the printer, and the surface quality of printed parts, so as to improve printing efficiency, ensure printing quality, and improve printing quality. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

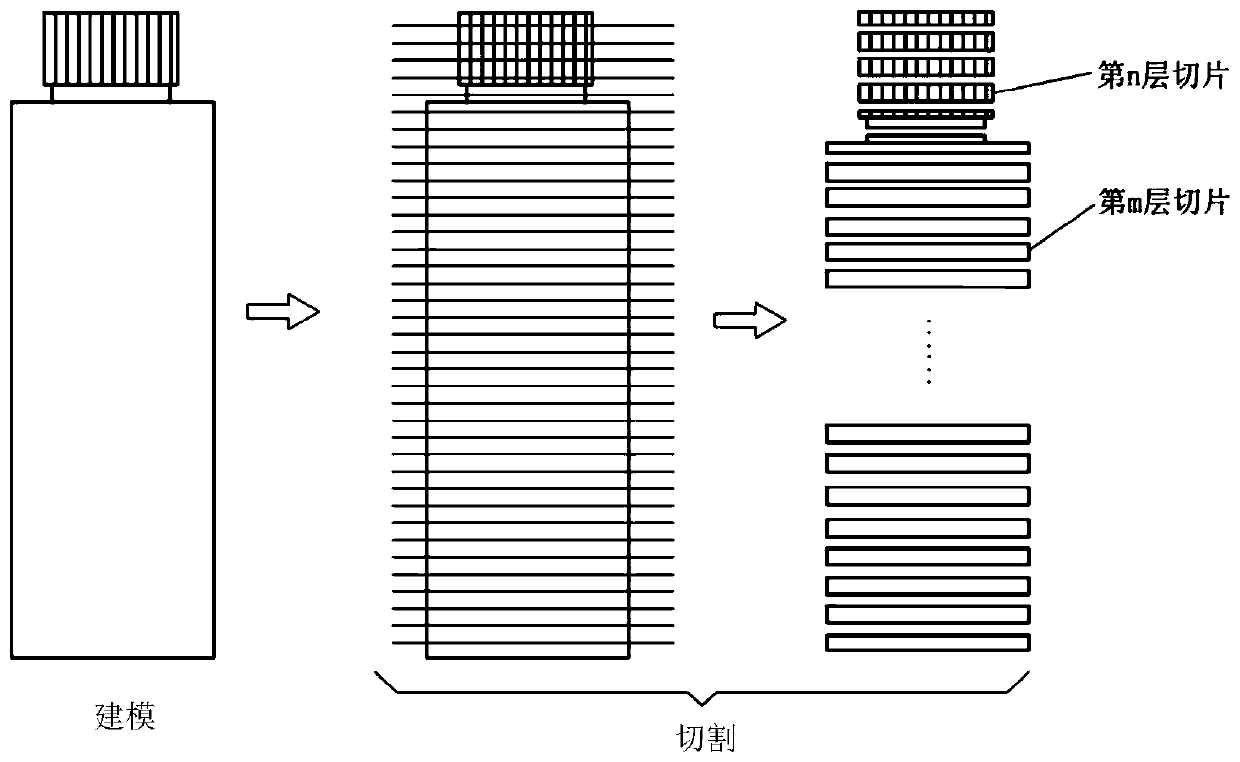

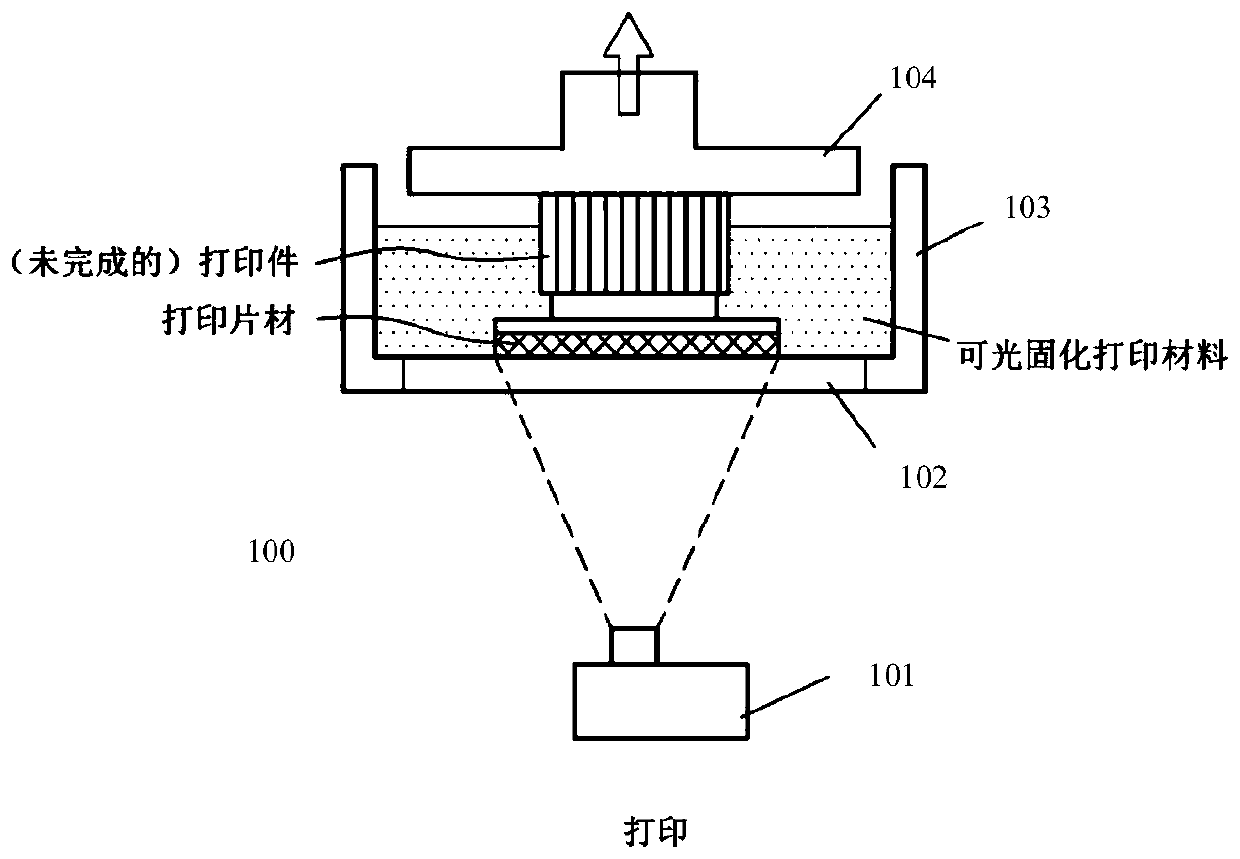

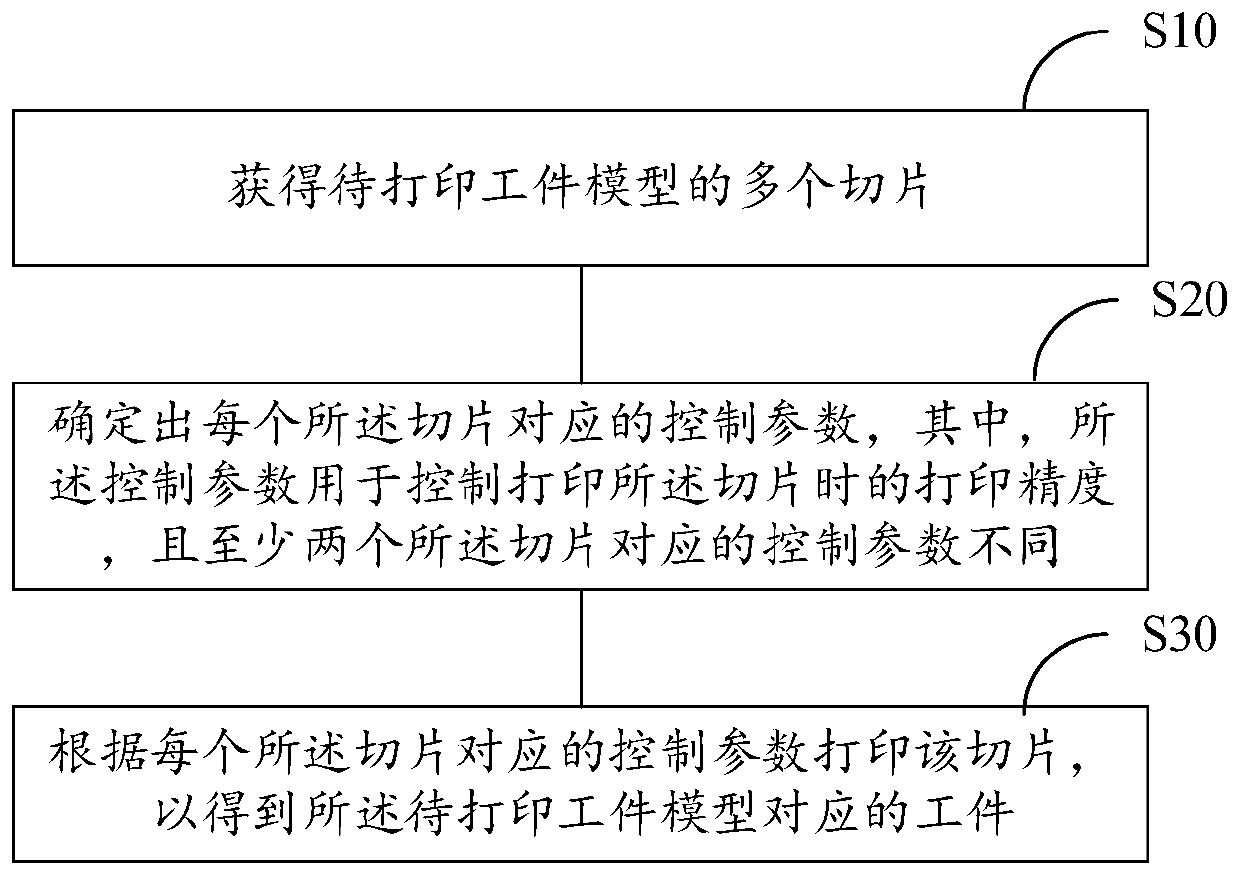

[0037] At present, 3D printing is well known to people, and 3D printers can realize 3D printing of workpieces, mainly through the following methods: such as figure 1 As shown in the figure, modeling is first performed by modeling software (modeling of the workpiece to be printed), and then the built 3D model is cut into layer-by-layer sections (that is, multiple slice layers are obtained by performing a slicing operation). The 3D printer 100 prints layer by layer according to the section, taking photocuring 3D printing as an example, as figure 2As shown, the printed part will be formed on the formed product table 104. After each layer of printed sheet is printed, the forming platform 104 will rise to the thickness of the next layer of slices (thickness of a new layer of printed sheet) , and then the light machine 101 projects light to the light-transmitting portion 102 at the bottom of the tray 103, and the photocurable printing material in the exposed area will polymerize an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com