A 3D printing system for array forming

A 3D printing, array-type technology, applied to 3D object support structures, coating devices, additive manufacturing, etc., can solve the problems of adjusting the number of selected nozzles and reducing the printing area, so as to improve printing efficiency and large printing space , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and example the patent of the present invention is described in detail.

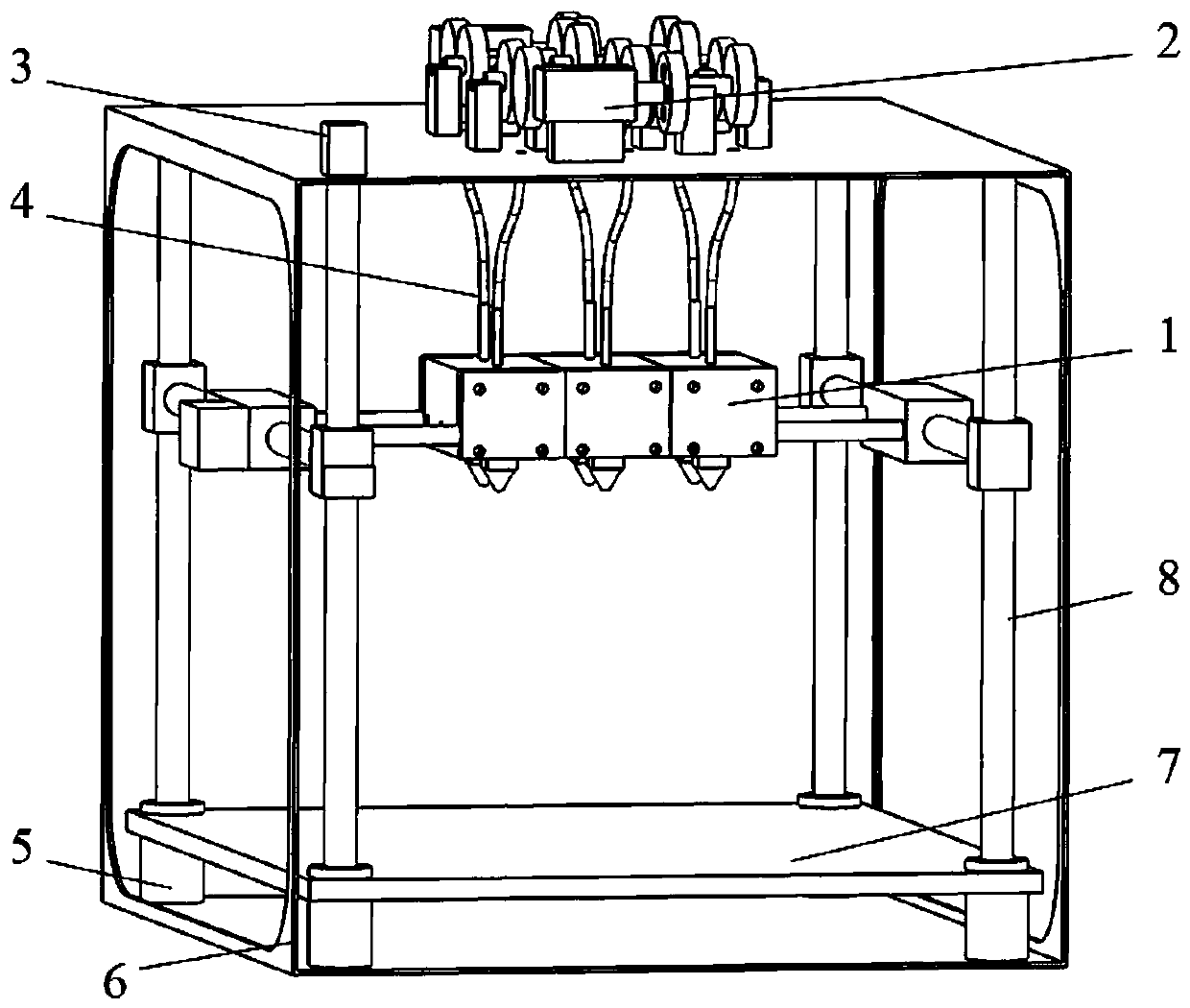

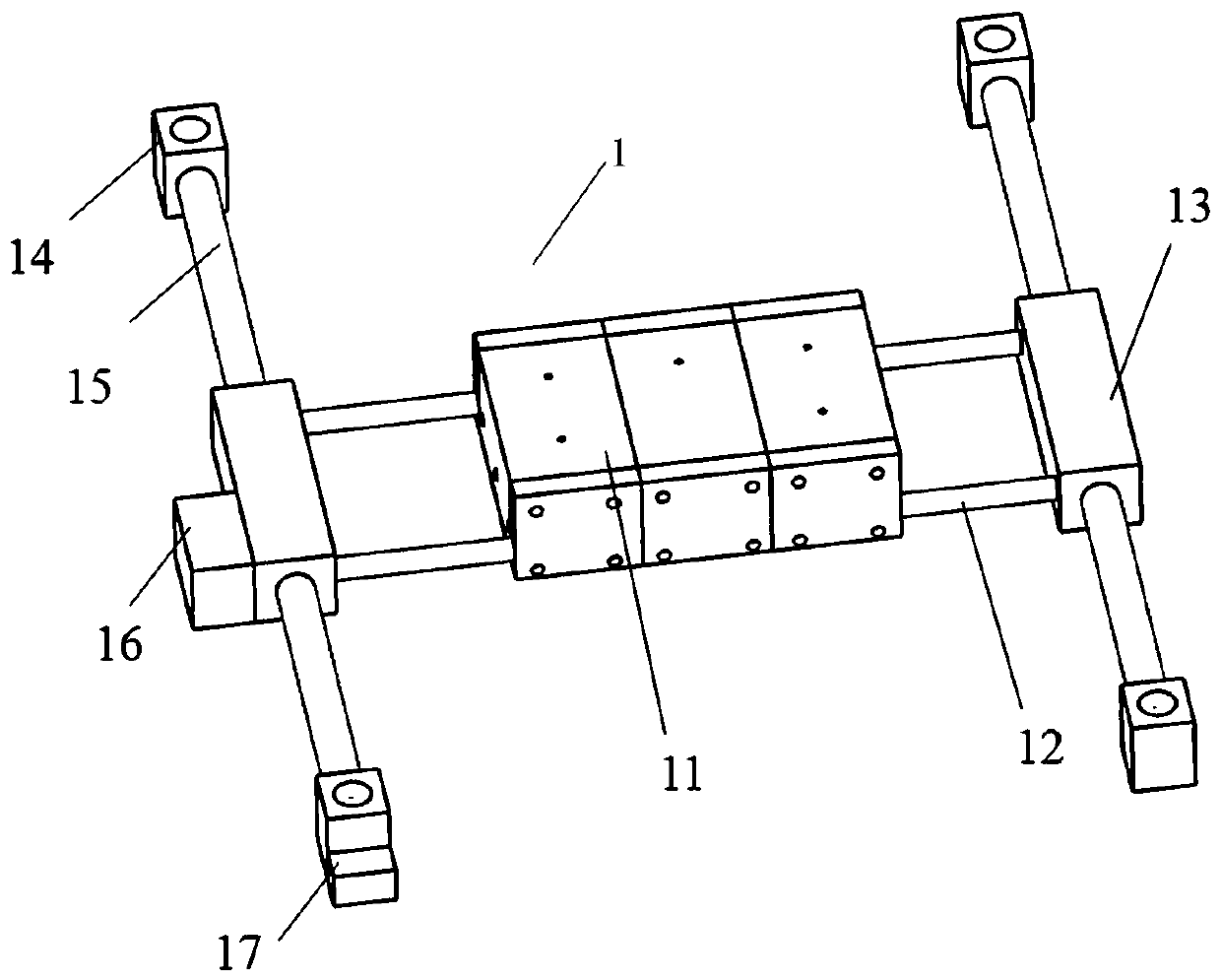

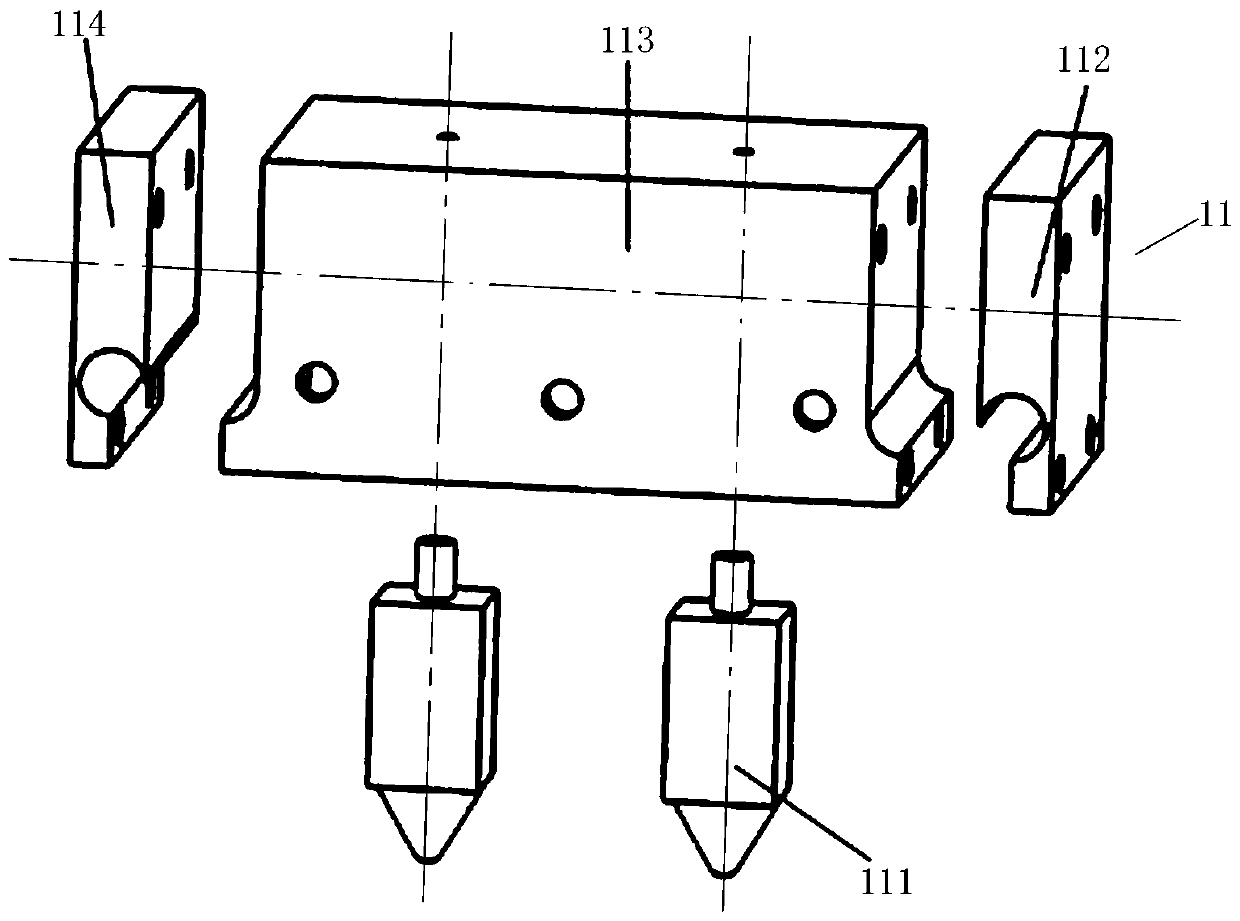

[0033] Such as figure 1 As shown, the patent of the present invention includes an array planar forming mechanism 1, a wire extrusion mechanism 2, a Z-direction driving motor 3, a feeding conduit 4, a printing platform fixing seat 5, a printer casing 6, a printing platform 7, and a Z-direction screw 8. Among them, such as image 3 As shown, the nozzles in the array plane forming mechanism 1 are composed of three detachable nozzles 11, and each detachable nozzle 11 contains two nozzles 111, that is, the array plane forming mechanism contains a total of six nozzles, which can print six nozzles at a time. pieces of the same product. Each detachable spray head 11 is made up of four parts: middle nozzle base 113, detachable fixed block one 112, detachable fixed block two 114 and nozzle 111, detachable fixed block one 112, detachable fixed block 114 and mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com