Copying double-sided glass edging machine

A kind of edging machine and double-sided technology, which is applied in the direction of machine tools, grinding machines, grinding/polishing equipment, etc., which are suitable for grinding the edge of workpieces, and can solve the problems of high price, low processing efficiency, difficulty in meeting large quantities of products and assembly line operation, etc. , to achieve the effect of convenient operation, high processing precision and low precision improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

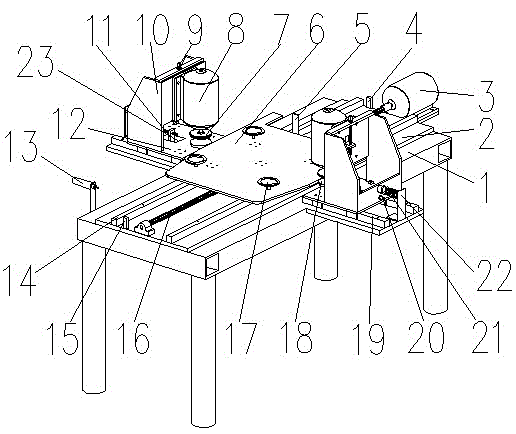

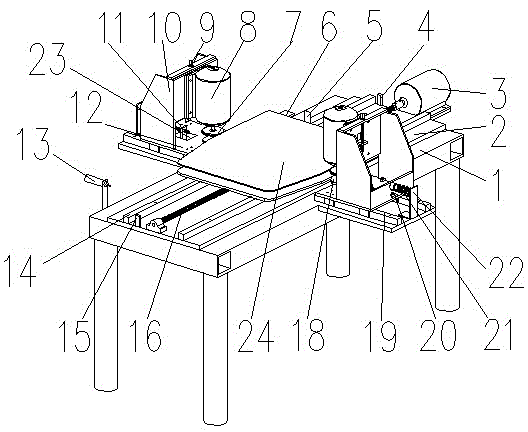

[0014] like figure 1 and figure 2 As shown, the profiling bilateral glass edging machine of the present invention includes a frame 1, a longitudinal feed drive motor 3 arranged on the frame 1, a longitudinal guide rail 14 arranged on the frame 1, and a longitudinal guide rail 14 slidingly connected to the frame 1. The vertical slider (not shown in the figure) on the top and the backing plate 6 arranged on the longitudinal slider, the power output end of the longitudinal feed drive motor 3 is connected to the feed screw 16 parallel to the longitudinal guide rail 14, and the feed The leading screw 16 passes through the longitudinal slider and is threadedly connected with the longitudinal slider. A group of edging devices are respectively arranged on the left and right sides of the template 6, and a vacuum suction cup 17 is provided on the template 6.

[0015] Each group of edging devices includes a transverse guide rail 19 arranged on the frame 1, a baffle plate 22 arranged at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com