Cobalt-based alloy overlay welding process for claws and small holes of connecting rods

A cobalt-based alloy and connecting rod technology, which is applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems such as uneven hardness, small hole space, and difficult operation, so as to improve the narrow space of surfacing welding, which is not conducive to implementation The difficulty of surfacing welding, the effect of improving the success rate and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

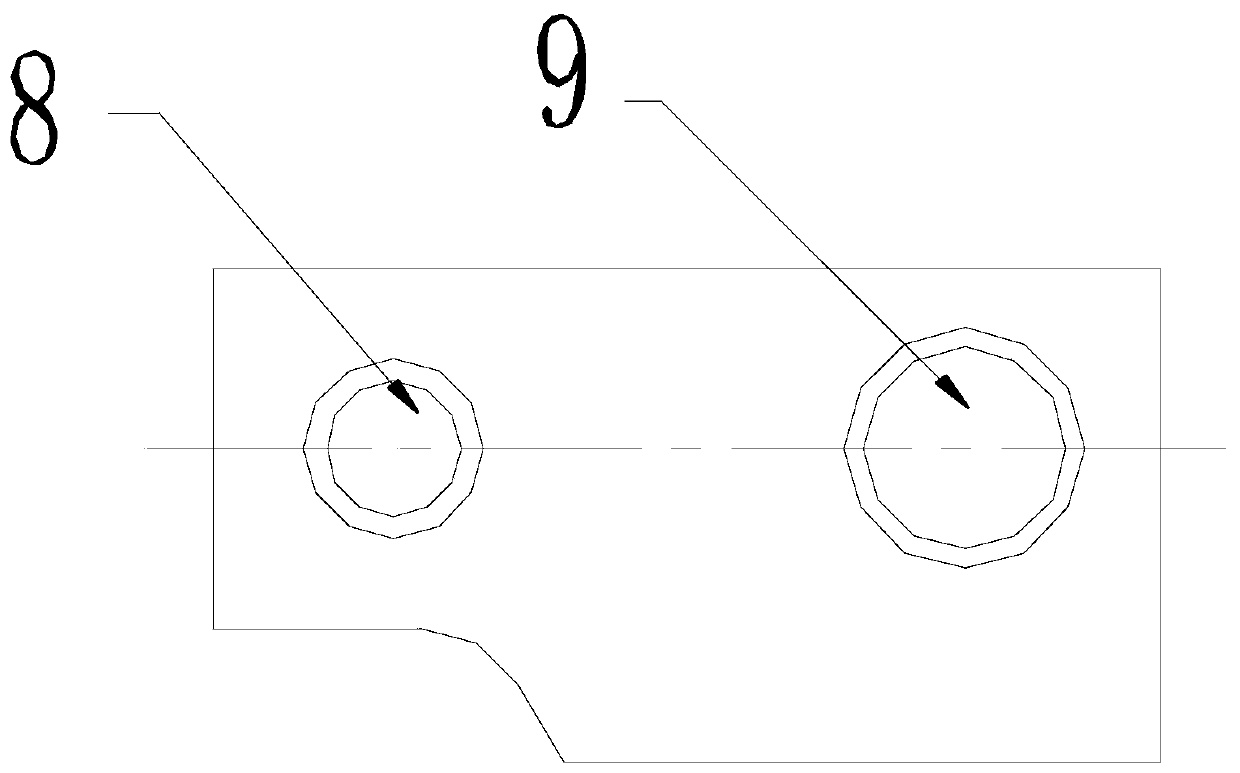

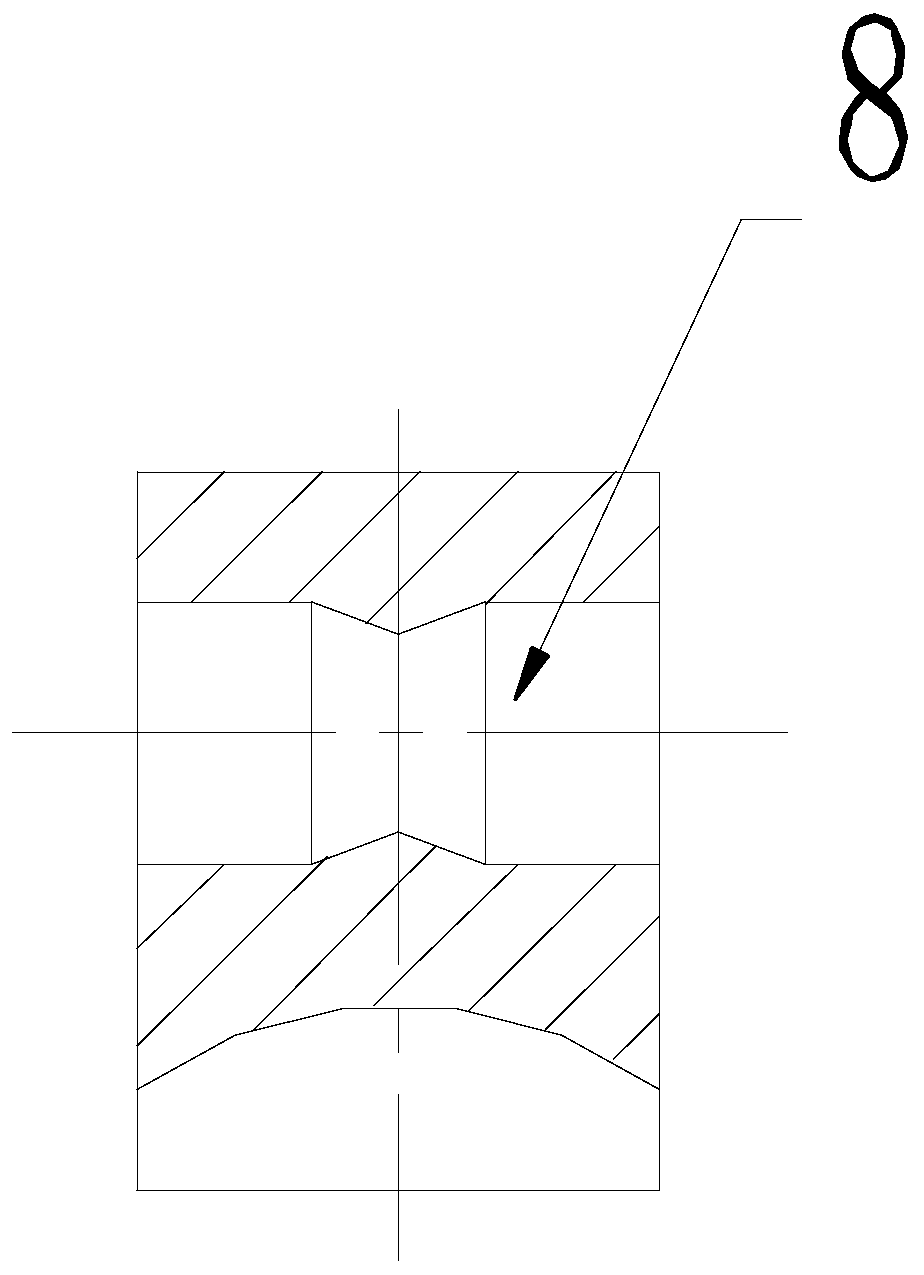

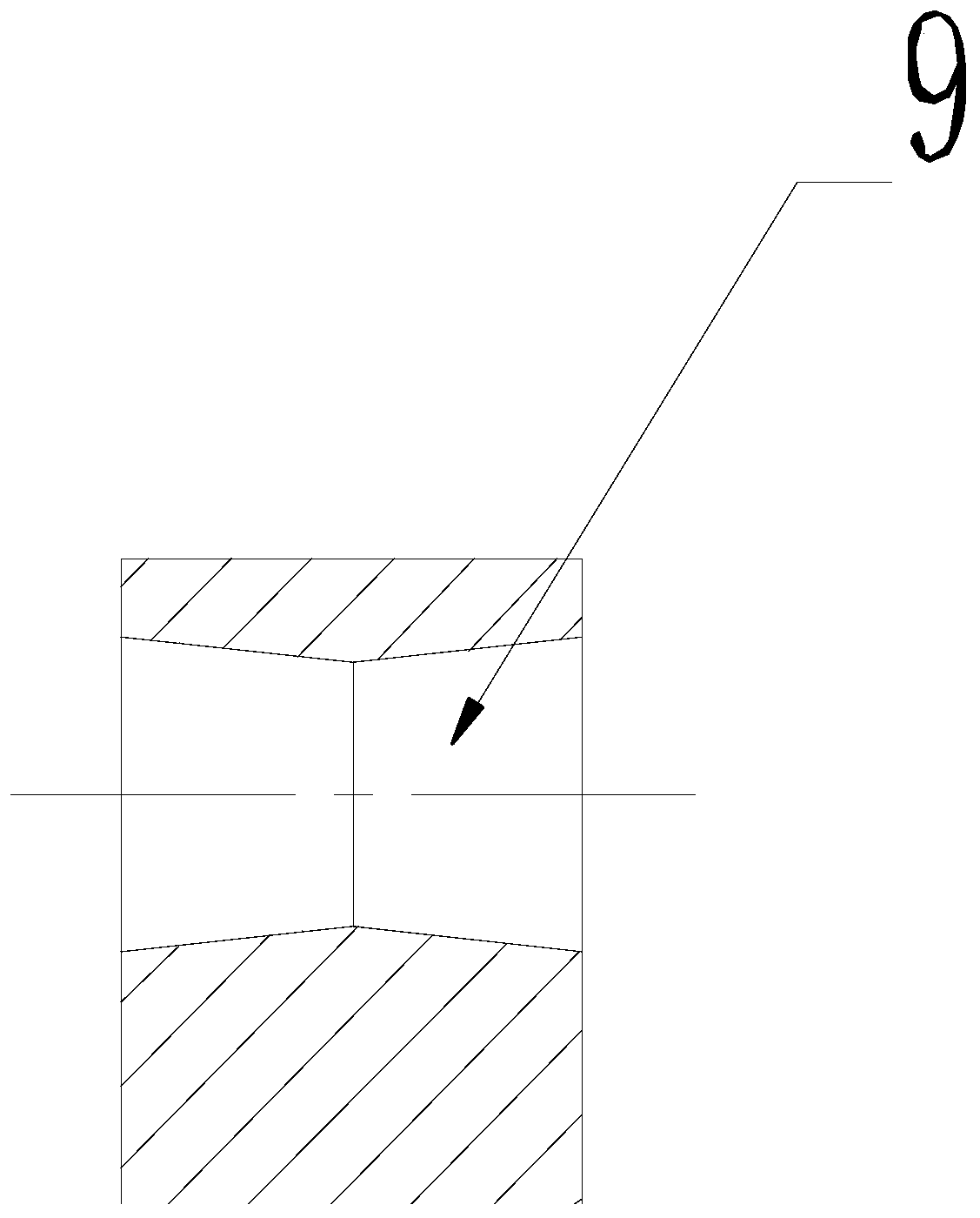

[0018] This application is used for the cobalt-based alloy surfacing welding process of the small holes of the claws and connecting rods, and the small holes are processed on the blank to be welded, such as figure 1 , figure 2 and image 3 As shown, the small hole includes a double-sided straight hole 8 and a double-sided tapered hole 9 . Wherein the double-sided straight hole 8 refers to all openings on two parallel surfaces of the workpiece 10 to be welded, and both openings are straight holes; the double-sided tapered hole 9 refers to the two parallel surfaces of the workpiece 10 to be welded Holes are opened on the top, and both holes are tapered holes. Before welding, the workpiece 10 to be welded is cleaned and preheated, and then surfacing is performed with an oxyacetylene flame. The surfacing blank structure is designed as double-sided straight holes 8 and double-sided taper holes. Compared with the direct surfacing welding of ordinary straight holes, first, it can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com