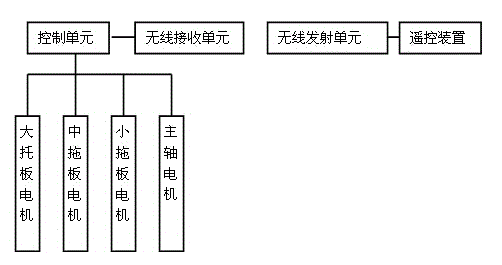

Control structure of C6031A floor-type lathe

A technology of C6031A floor lathe, which is applied in the field of control structure of C6031A floor lathe, can solve the problems of cumbersome equipment operation and easy safety accidents, and achieve the effect of convenient operation, reduction of manpower and processing time, and good use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Such as figure 1 As shown, a control structure of a C6031A floor lathe, including a remote control device, the remote control device is connected to the wireless receiving unit of the control unit of the lathe through a wireless wireless transmitting unit, and the control unit is connected with a large pallet motor, a medium pallet motor, and a small pallet motor. The carriage motor and the spindle motor, the remote control device is provided with a large carriage motor button, a middle carriage motor button, a small carriage motor button and a spindle motor button, and the present invention adopts remote control to realize the movement of each motor connection of the C6013A floor lathe The start, stop, jog, linear feed, etc. of parts can be operated by one person through remote control, and the processing status can be directly observed. The operation is convenient and easy to control, reducing manpower and processing time, and improving work efficiency. It reduces the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com