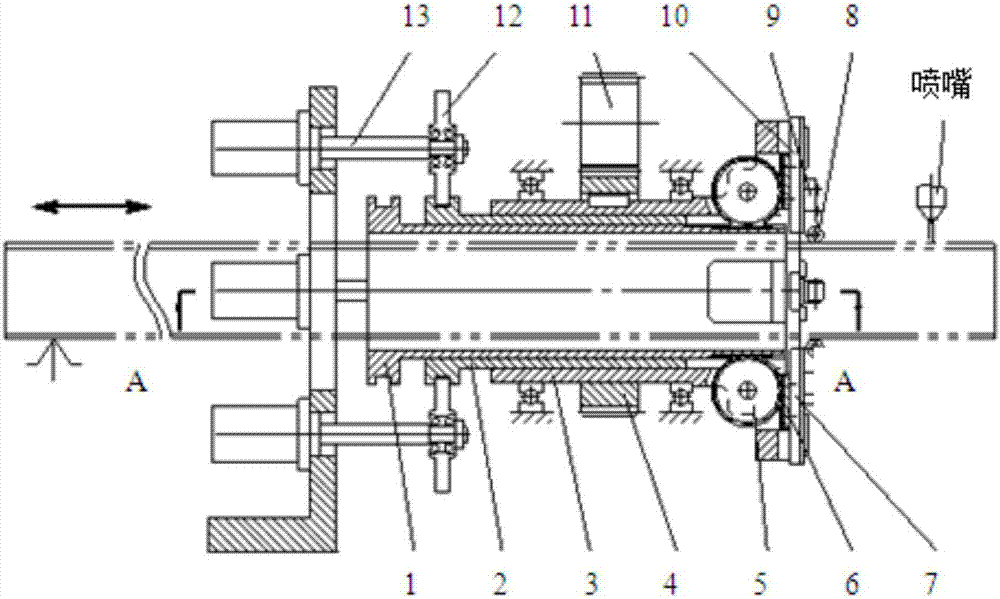

A self-centering chuck and cutting device for cutting square tubes

A self-centering and collet technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of complex fixture structure, bulky volume, high manufacturing cost, etc., and achieve wide application range, miniaturized structure size, The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

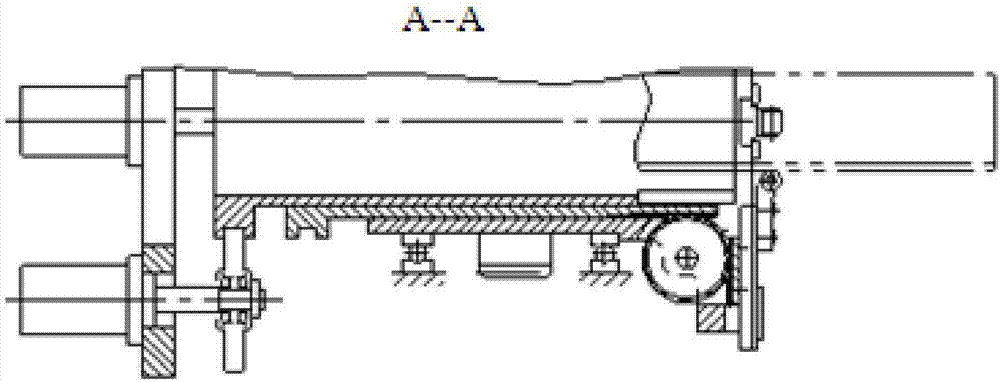

[0033] The self-centering chuck for cutting square tubes includes an inner sleeve, an outer sleeve and a hollow main shaft installed coaxially from the inside to the outside. The axis rotates; on the outer cylindrical surface of the inner sleeve and the outer sleeve, one end is respectively connected to a driving cylinder that drives it to move along the axis of the hollow main shaft, and the other end is respectively meshed with a transition gear, and the transition gear is fixed on the hollow main shaft , rotates synchronously with the hollow main shaft; at the same time, the transition gear meshes with the rack mounted on the slide plate, the slide plate is installed in the radial direction of the hollow main shaft, perpendicular to the axial direction of the hollow main shaft, and the tooth The axial direction of the bars is also perpendicular to the axial direction of the hollow main shaft. And a clamping device for clamping the workpiece is installed on the slide plate; ...

Embodiment 2

[0054] A square pipe cutting device, comprising the self-centering chuck described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com