Axle component for a motor vehicle axle

A technology for shaft parts and motor vehicles, which is applied to motor vehicles, vehicle parts, cantilevers mounted on pivots, etc., can solve problems such as skewing of the supporting shell, avoid skewing or jamming, and achieve the effect of self-centering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the various figures, the same reference numerals are used for identical or similar components, even if a repeated description is omitted for reasons of simplification.

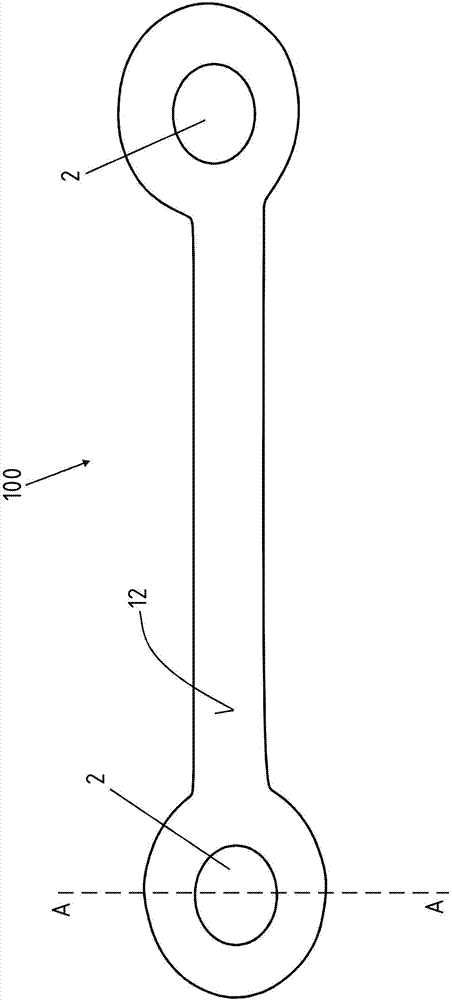

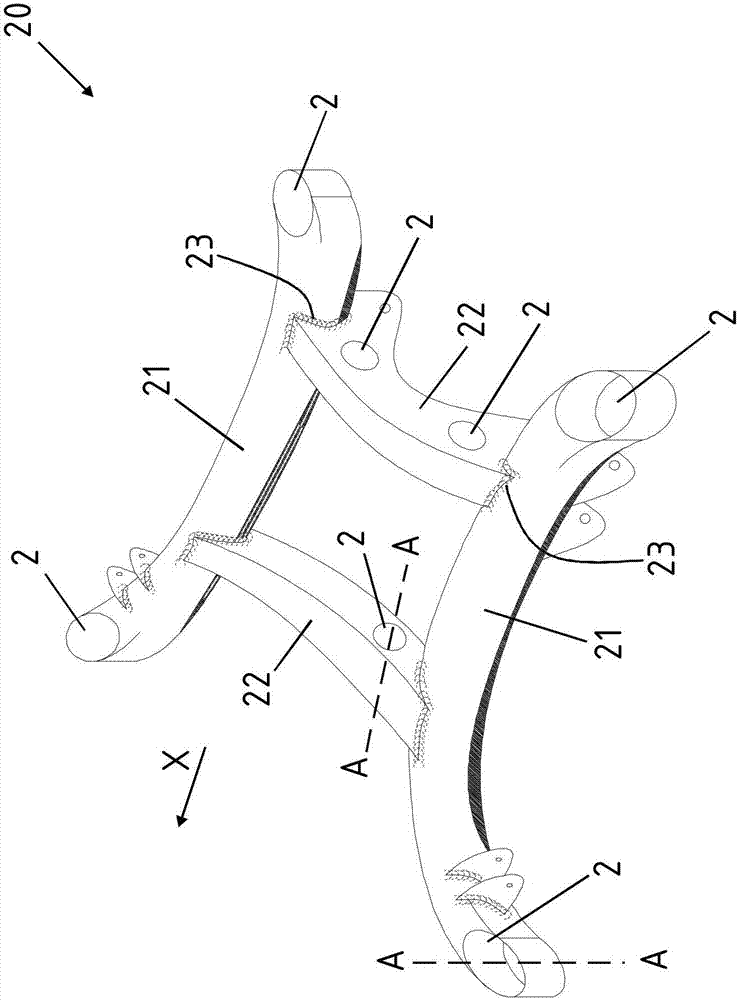

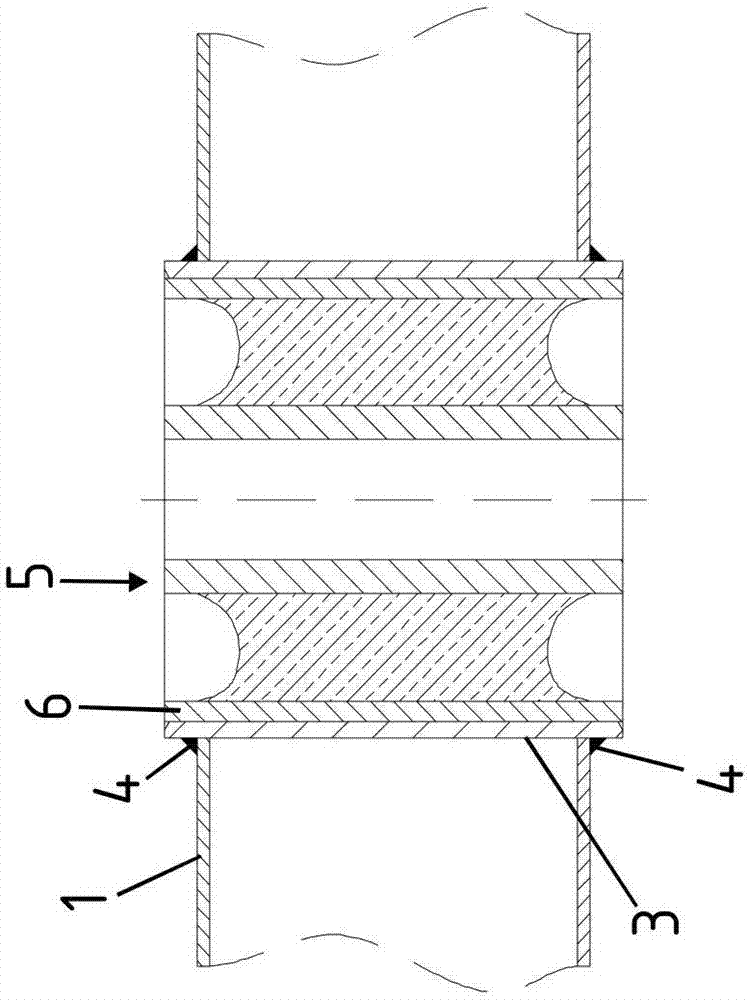

[0026] Figure 1a A similar guide rod 100 is shown in rod form. The link has an elongated extension and at its respective end each has a bearing receptacle 2 for receiving a rubber-metal bearing not described in detail. exist Figure 1b A similar shaft bracket 20 is described in . The axle carrier has two longitudinal frame parts 21 , which are each oriented laterally in the longitudinal direction X of the motor vehicle, and a transverse bridge 22 connecting the longitudinal frame parts. The longitudinal frame elements 21 and the transverse bridges 22 are each coupled to each other by weld seams 23 . The longitudinal frame parts 21 and / or the transverse bridges 22 are formed as extruded profiles or sheet metal profiled components. In particular, however, it is designed as a hollow component and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com