Switchable gear clutch

A gear clutch, gear ring technology, applied in the direction of clutch, intermeshing clutch, mechanical drive clutch, etc., can solve the problem that the teeth cannot be fully overlapped.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

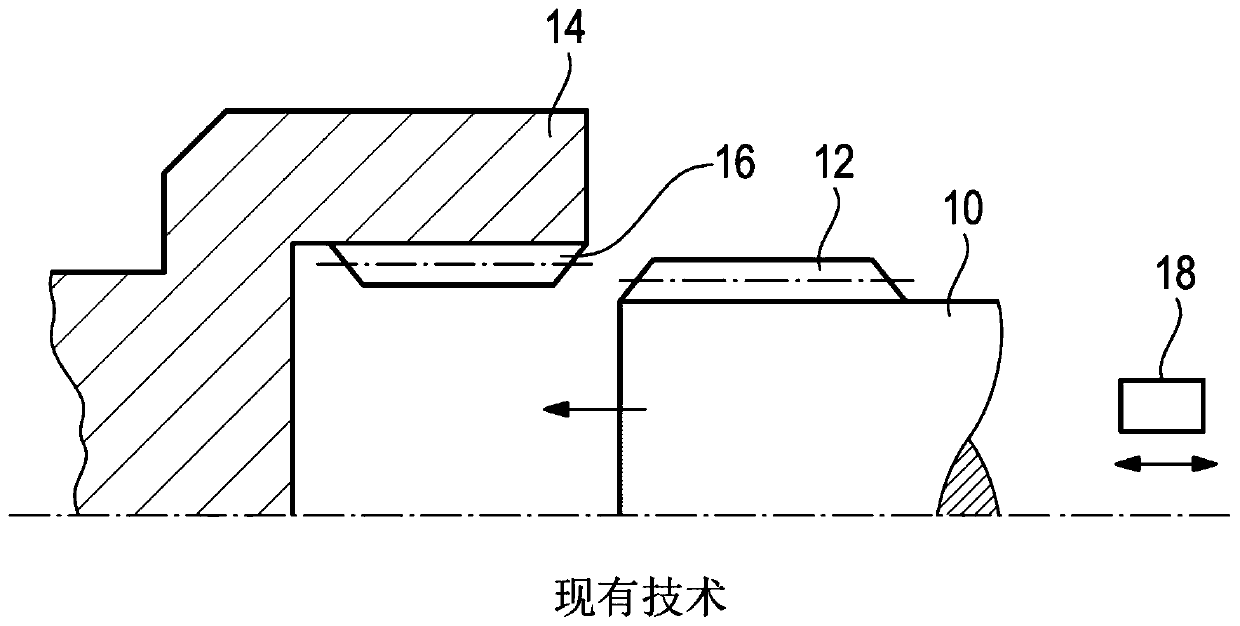

[0020] figure 1 A tooth clutch according to the prior art is shown, which has a shaft 10 which carries an external toothing 12 which is cut into the shaft. The hub 14 has a corresponding internal toothing 16 . Shaft 10 or hub 14 can be moved axially towards the respective other part via actuator 18 (see figure 1 double arrow in ), so that the teeth 12, 16 mesh with each other and can transmit torque.

[0021] from figure 1 It can be easily seen from the figure that in order to completely or at least partially shift the toothing 12 , 16 in an alternating manner, a relatively large switching path and thus a long switching time are required.

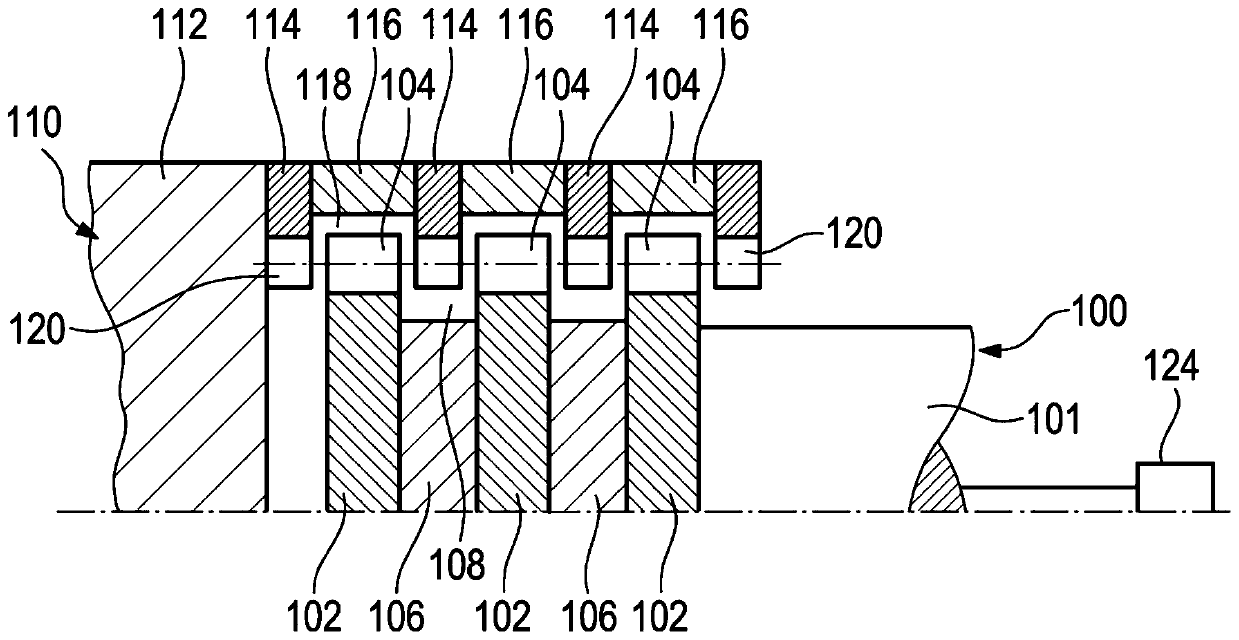

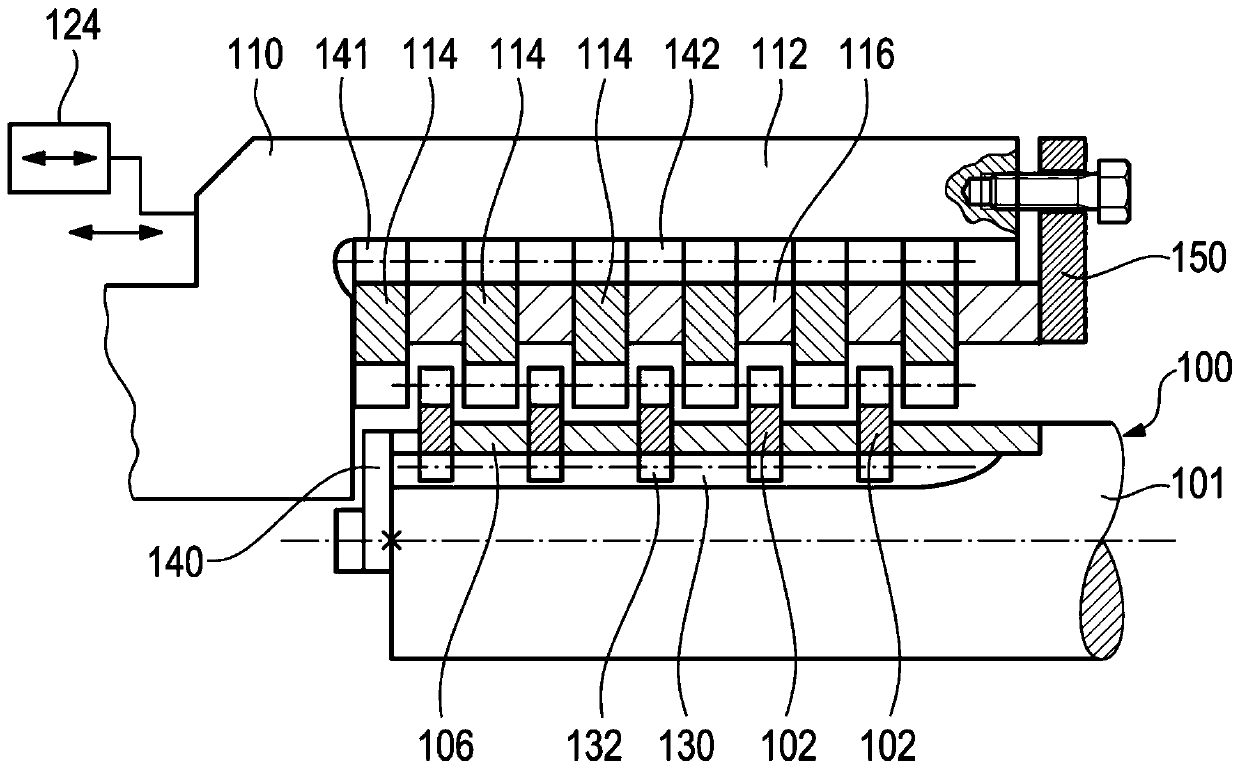

[0022] figure 2 shows a switchable dog clutch in which the figure 1 The toothing 12 , 16 shown is divided so to speak into individual toothings spaced apart from one another.

[0023] The shaft 100 has a shaft body 101 . The shaft carries or has a plurality of toothed rings 102 which are preferably designed as one piece and each hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com