Multi-stage hybrid powertrain for a motor vehicle

A technology of hybrid power and power train, applied in the direction of arrangement of multiple different prime movers of hybrid vehicles, motor vehicles, general power plants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

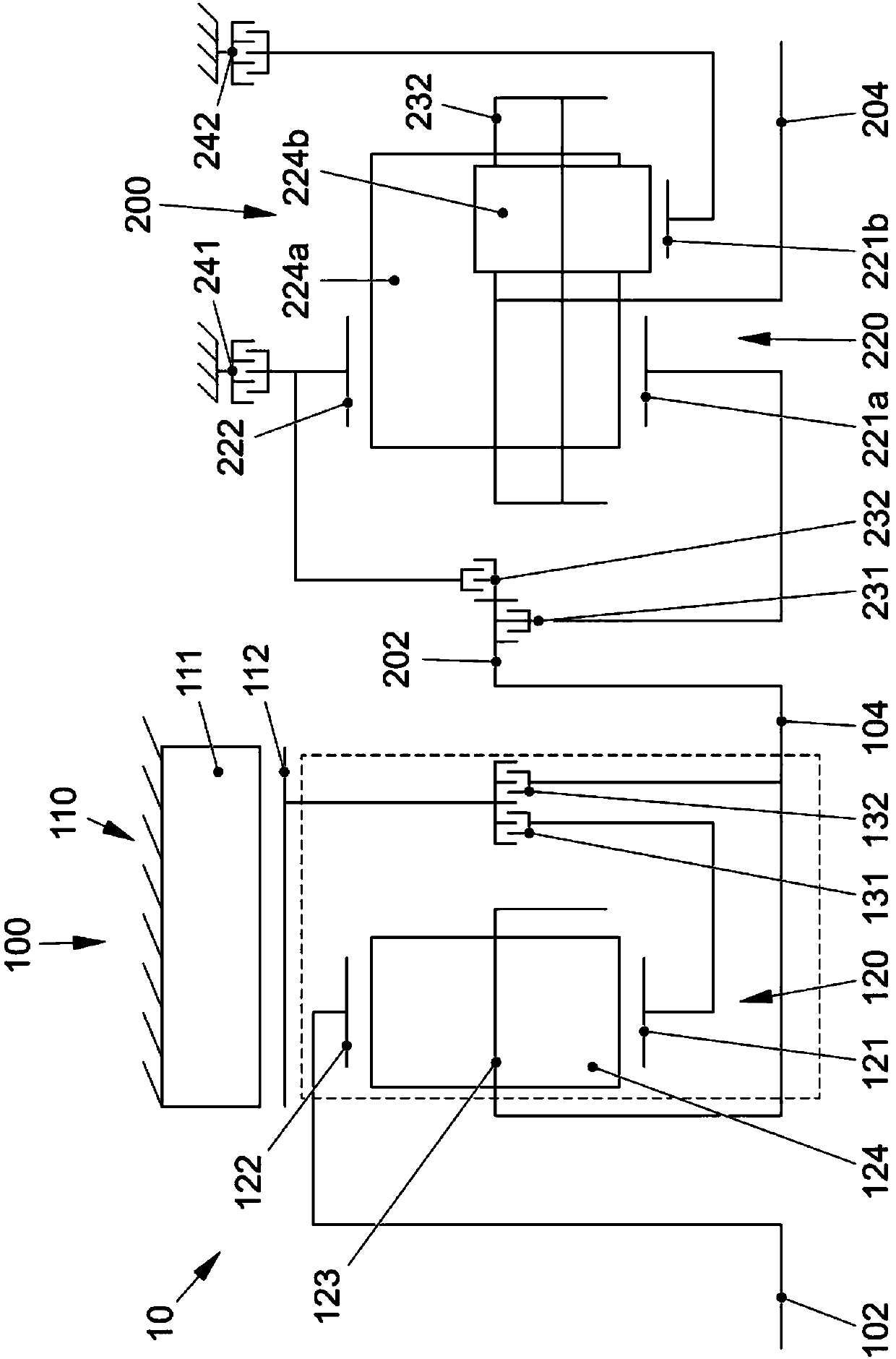

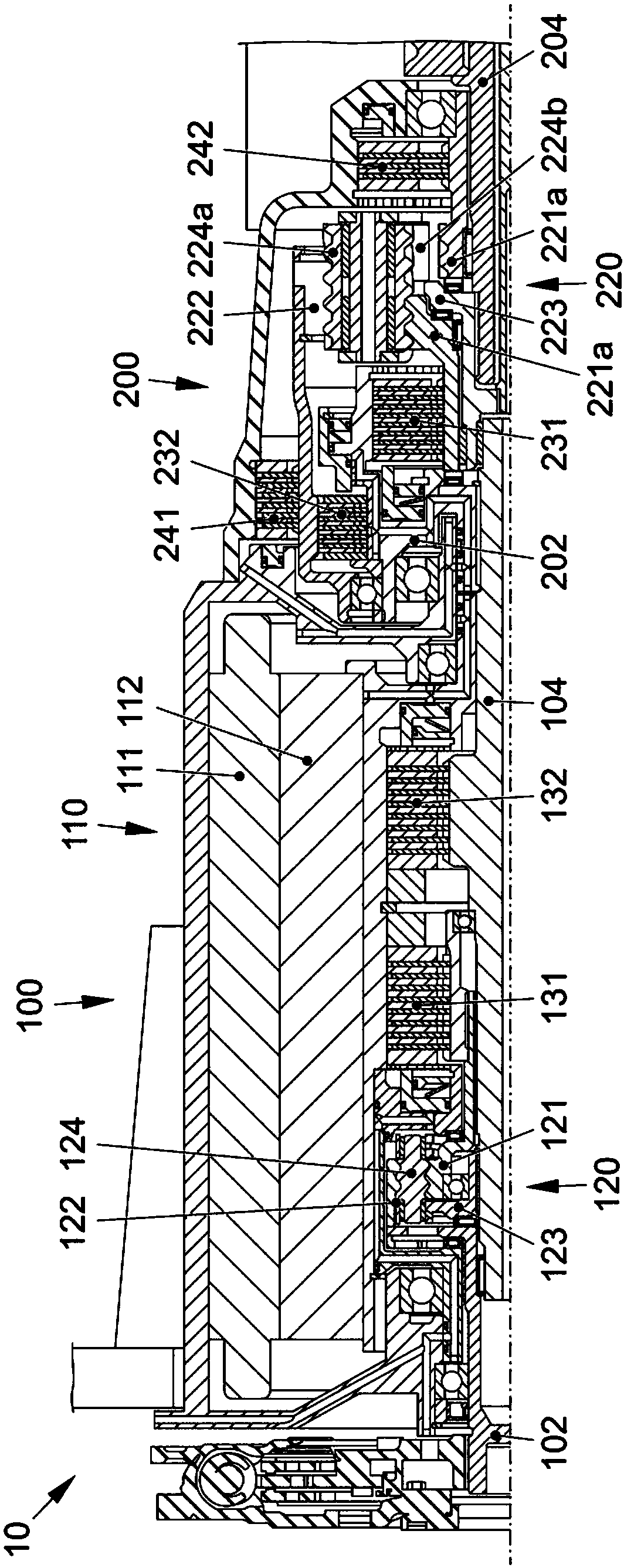

[0036] figure 1 A schematic topological view of an embodiment of the drive train 10 according to the invention is shown. The powertrain 10 includes an input stage 100 and a secondary 200 .

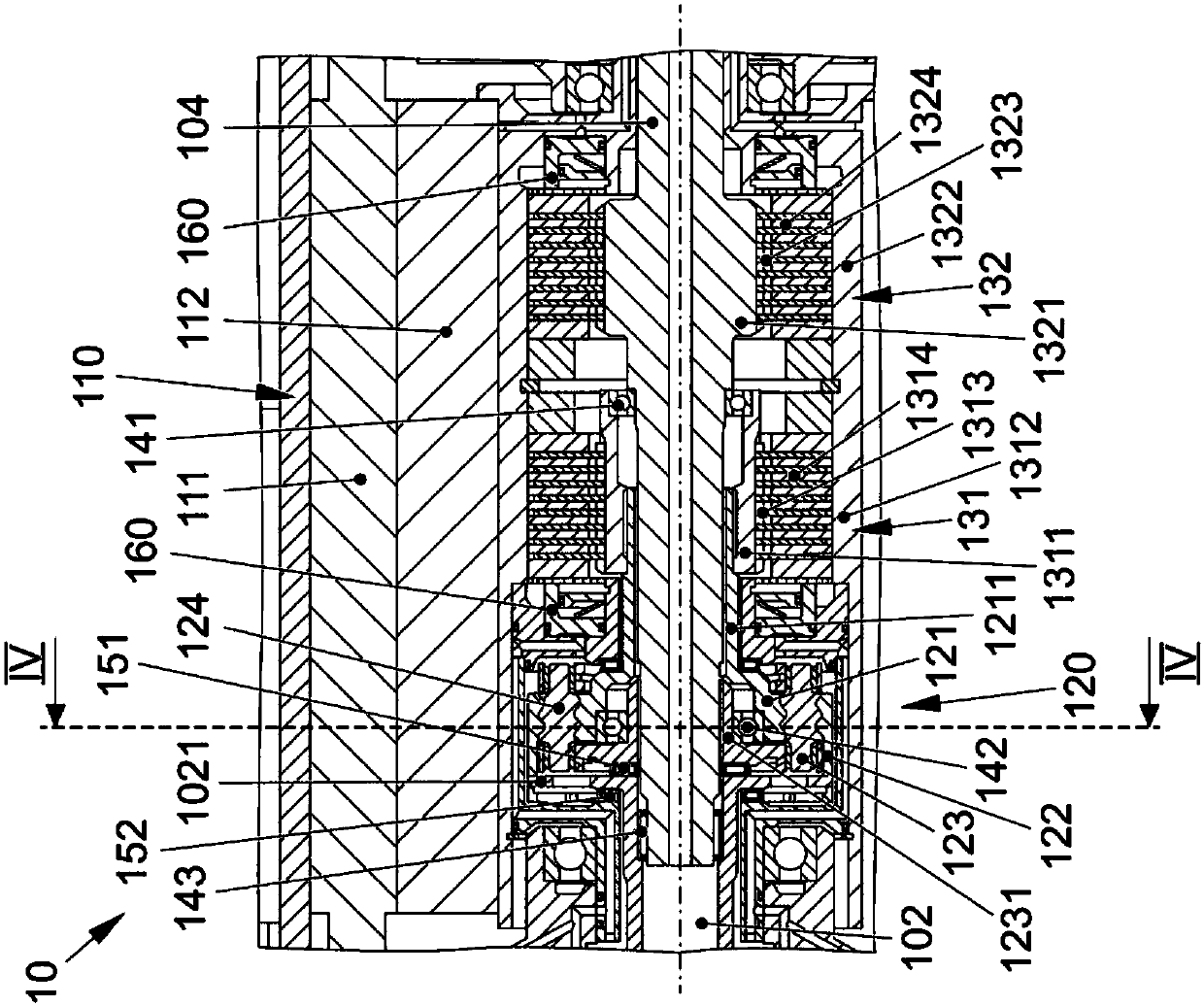

[0037]The input stage 100 comprises a stage input shaft 102 on the input side, a stage output shaft 104 on the output side, an electric motor 110 with a stator 111 fixed to the housing and a rotatably mounted , the inner rotor 112, the planetary gear set is designed in the embodiment shown as a simple planetary gear set, which has a sun gear 121, a ring gear 122 and a planet carrier 123, on which the planetary gear is rotatably mounted A set of planetary gears 124 meshes with the sun gear 121 on the one hand and with the ring gear 122 on the other hand.

[0038] The stage input shaft 102 is fixedly connected with the ring gear 122 . The stage output shaft 104 is fixedly connected to the planet carrier 123 . The rotor 112 of the electric machine 110 is coupled to the sun gear 121 via a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com