crankcase and internal combustion engine

A technology for crankcases and internal combustion engines, applied in the field of crankcases, can solve problems such as pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

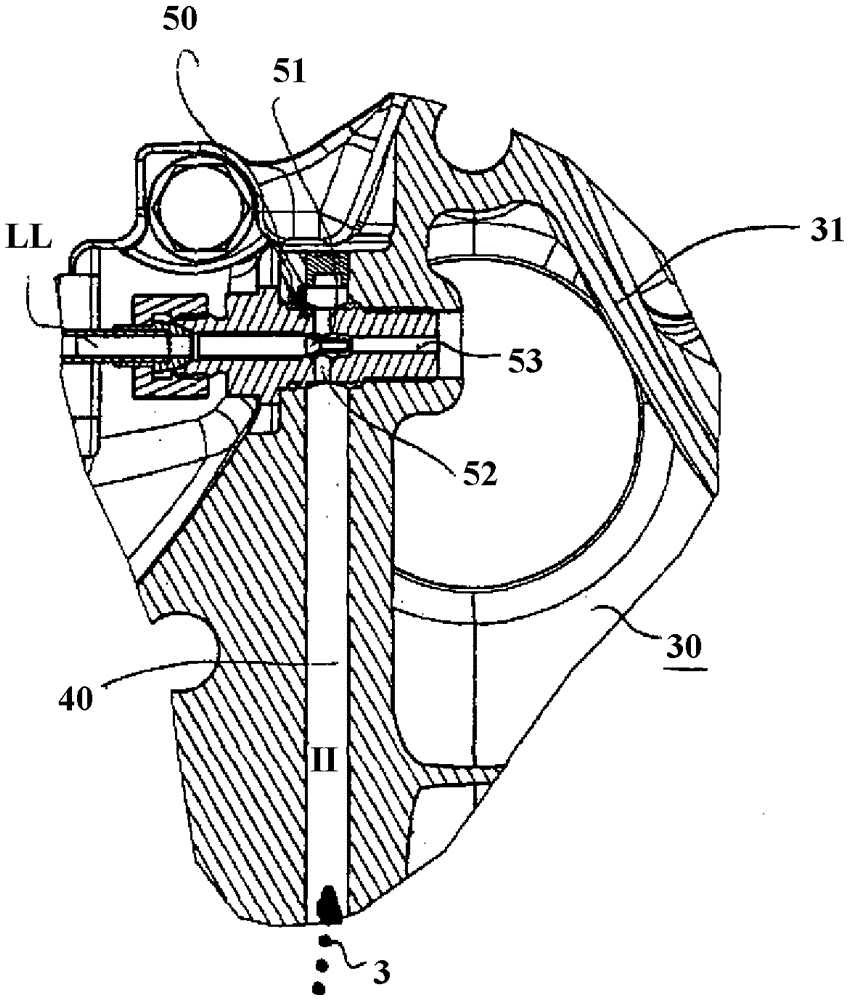

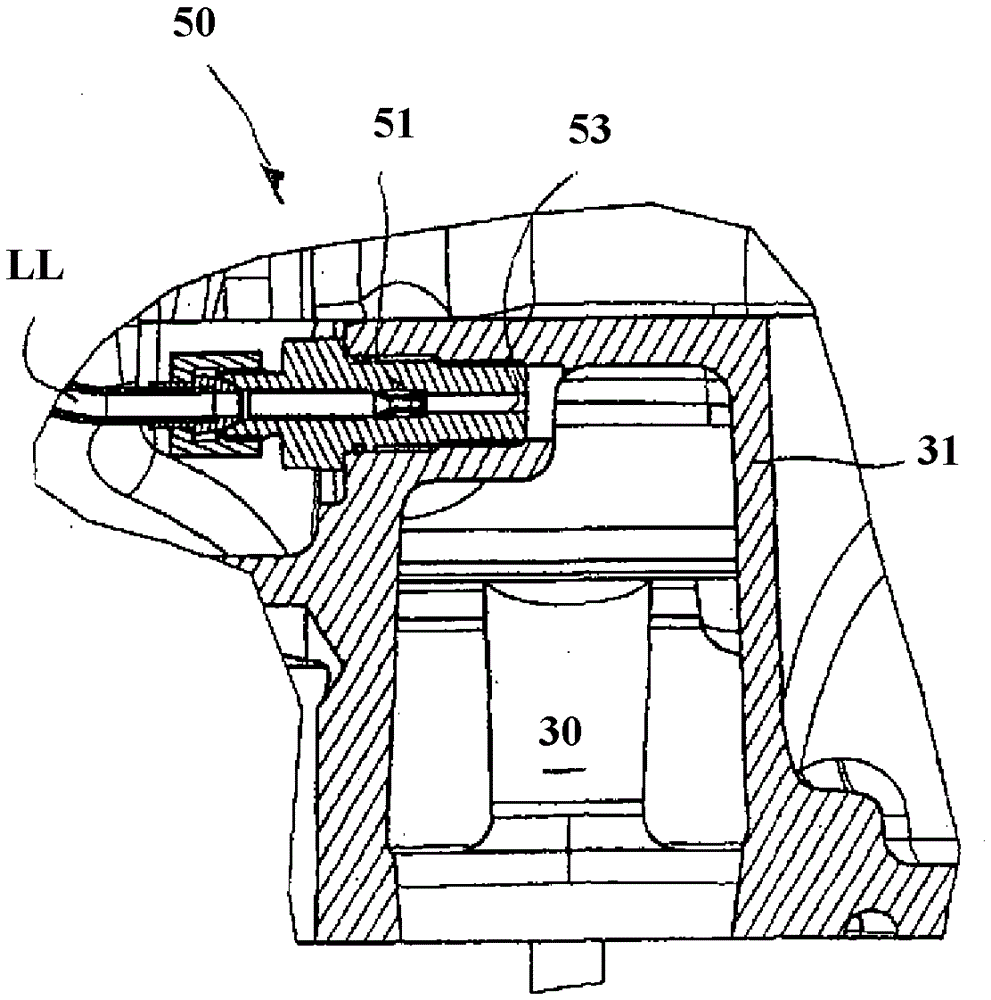

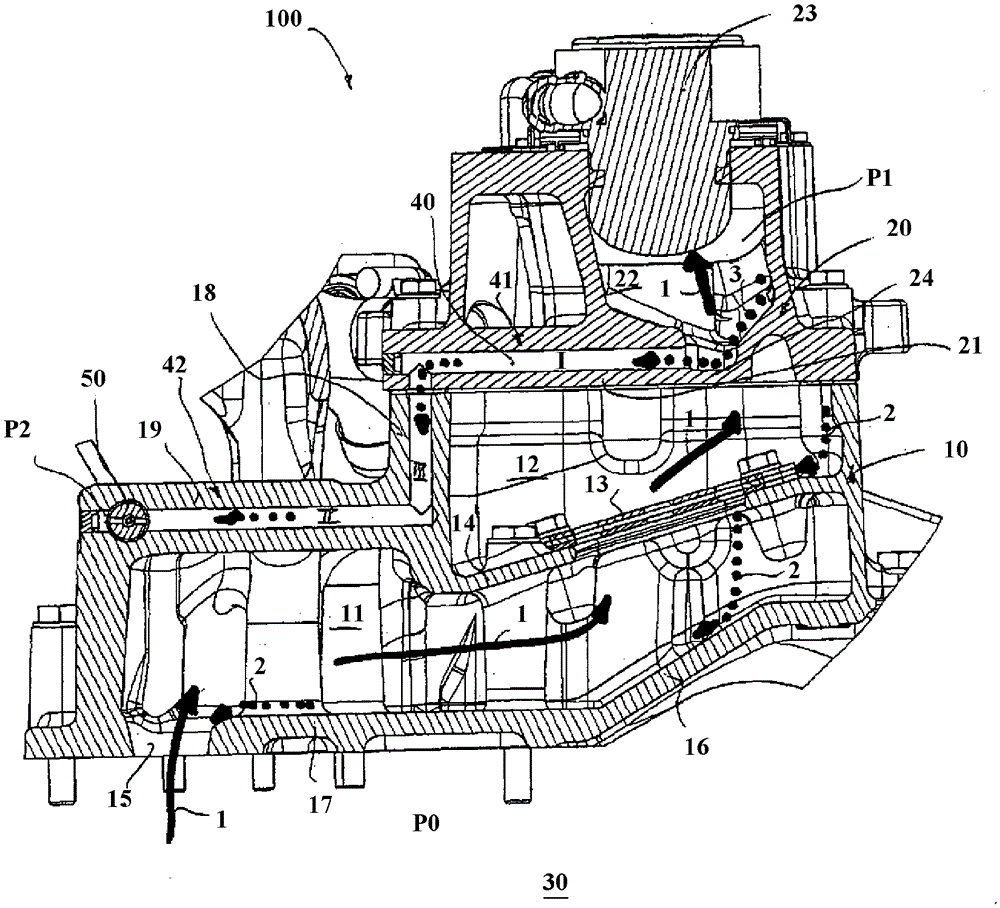

[0032] figure 1 A crankcase 100 for an internal combustion engine, not shown in detail, is shown. Presently, the upper part of a crankcase 100 is shown with the ventilation housing part 10 and the carrier housing part 20 arranged thereon. The crank chamber 30 of the crankcase 100 is located below the ventilation housing part 10 , in which the cylinder head, the crankshaft and finally also the oil sump are arranged one above the other. Blow-by gas 1 mixed with oil is conducted here from crankshaft chamber 30 via one or more channels to almost the highest point of crankcase 100 . In principle, such channels, not shown in detail here, can be integrated not only in the crankcase casting, but also as external channels (such as hoses or lines, etc.). The leakage gas 1 is introduced into the ventilation housing part via the opening 15 , which is largely protected from spray oil. A further embodiment of both the ventilation housing part 10 and the carrier housing part 20 serves to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com