Engine cylinder wedge-shaped centering clamp

A technology for engine cylinder blocks and centering fixtures, applied in clamping, positioning devices, manufacturing tools, etc., can solve the problems of uncontrollable positioning, the inability to truly determine the center of the cylinder liner hole, and the inability to ensure the consistency of the B reference, etc., to eliminate Tolerance, uniform finishing allowance, avoiding unilateral effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

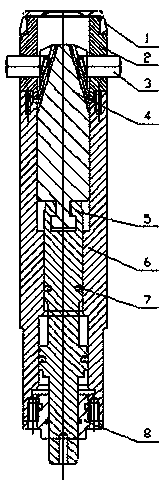

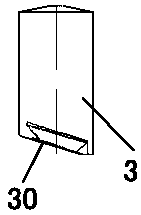

[0019] Such as Figures 2 to 5 A wedge-shaped centering fixture for an engine block shown includes a guide sleeve with a main guide hole and a positioning mechanism that is matched and connected with the guide sleeve. The positioning mechanism includes more than three positioning slide chucks 3 and each positioning The sliding part of the transmission connection of the sliding chuck 3; the positioning sliding chuck 3 is arranged radially in the positioning guide hole on the side of the guiding sleeve, the sliding part is arranged in the main guiding hole of the guiding sliding sleeve, and the shafts of each positioning guiding hole The direction is in the same plane perpendicular to the axial direction of the main guide hole; the tails of each positioning sliding chuck 3 are connected with a plurality of dovetail grooves 40 on the slider in one-to-one correspondence, and the dovetail grooves 40 are relatively connected to the main guide hole. The axial direction is inclined, a...

Embodiment 2

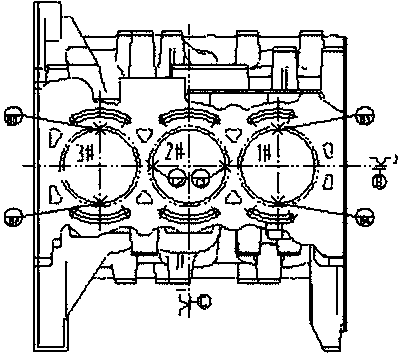

[0027] Such as Figures 6 to 7 , a positioning device for an engine block, comprising a clamp body 9, the clamp body 9 is provided with two positioning holes 10 corresponding to the cylinder liner on the engine block 11, and the wedge-shaped positioning of the engine block as described above is arranged in the positioning holes 10. centering fixture, the centering fixture is connected with the upper surface of the clamp body 9 through the reference end surface of the fixed base 6, and the lower end of the sliding seat pull rod 5 of the centering fixture runs through the positioning hole and is connected with a power mechanism; the upper surface of the clamp body 9 is also set There are a plurality of positioning bosses 12 for supporting the engine block 11, and the upper parts of the plurality of positioning bosses 12 are in the same plane parallel to the reference end surface of the centering fixture.

[0028] The engine block 11 is positioned by the bottom surface and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com