A self-centering wear-free rotating barrel device

A non-abrasive, self-centering technology, used in barrel/cask filling, liquid filling, etc., can solve the problems of material barrel deformation, bumping into material barrels, material barrel deformation, etc., to reduce the probability of damage and protect the barrel. body, the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention provides a self-centering non-abrasive rotating drum device and its rotating drum method. In order to make the purpose, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

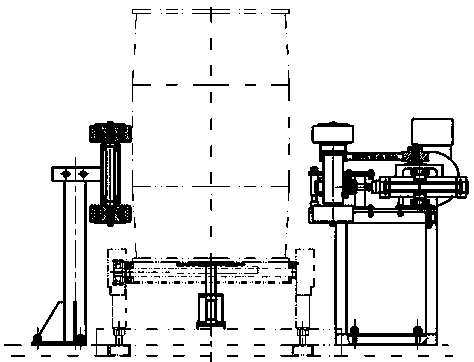

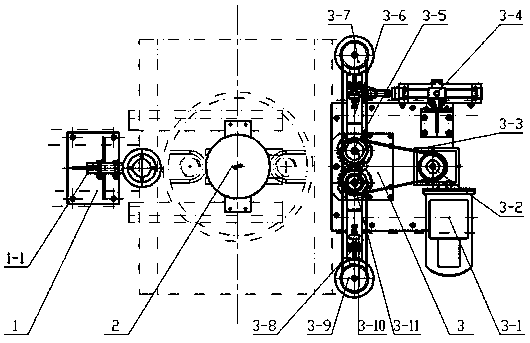

[0025] The invention provides a self-centering and wear-free drum rotating device, which includes a positioning mechanism, a drum lifting mechanism and a drum rotating mechanism.

[0026] The positioning mechanism includes a positioning bracket and a free wheel train. The freewheel train is made up of two freewheels made of nylon, a freewheel seat and a rotating shaft. The free wheel made of nylon can minimize the damage to the material barrel during the positioning of the holding barrel and the turning of the barrel. And the free whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com