Self-centering clamping device adopting single-point driving mode

A self-centering clamping, single-point technology, used in positioning devices, clamping, supporting and other directions, can solve the problems of hidden safety hazards, time-consuming and laborious, and stability defects of fixed objects, and achieve the effect of strengthening stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

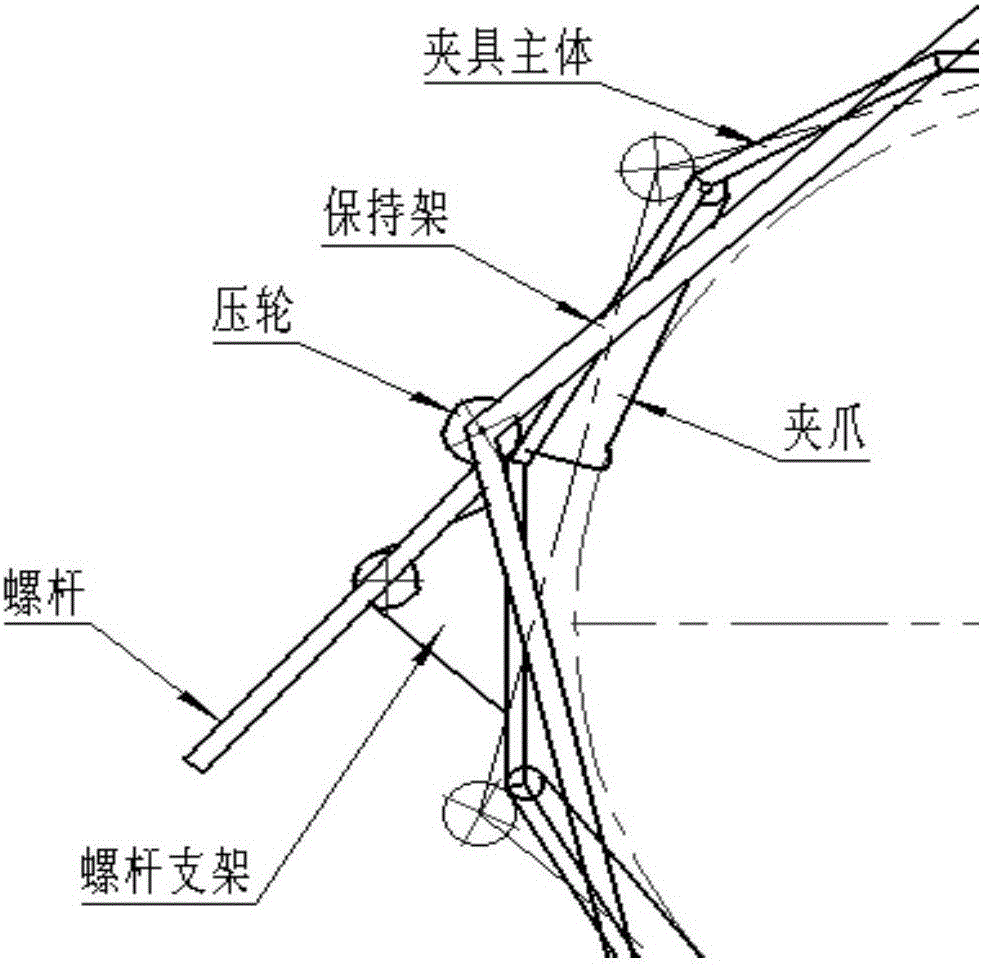

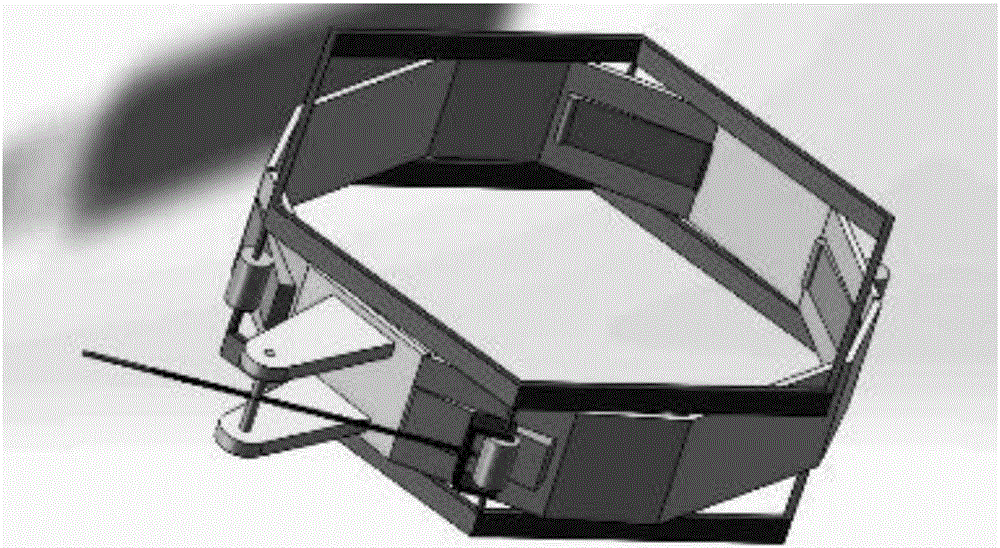

[0012] The self-centering clamping device with single-point drive is mainly composed of clamping jaws fixed on the main body of the fixture that can swing around the axis, rotatable pressure rollers installed between the upper and lower cages, cages and screws that apply driving force . When the device works, the screw rod passing through the fixed nut on the screw rod bracket is rotated, and the screw rod pulls the cage to move. The pressure roller installed on the cage, driven by the cage, moves along the outer wall of the fixture body, and presses the swingable jaws to the inside of the fixture body to complete the clamping action. Driven by the cage and acted by the four jaws, the four pressure rollers move inward at the same time to complete the clamping action and realize the self-centering function.

[0013] The device of the present invention provides a self-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com