Improved three-jaw composite chuck

A technology of composite chuck and disc body, applied in the direction of chuck, etc., can solve the problems of inability to clamp irregular workpieces and narrow use range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

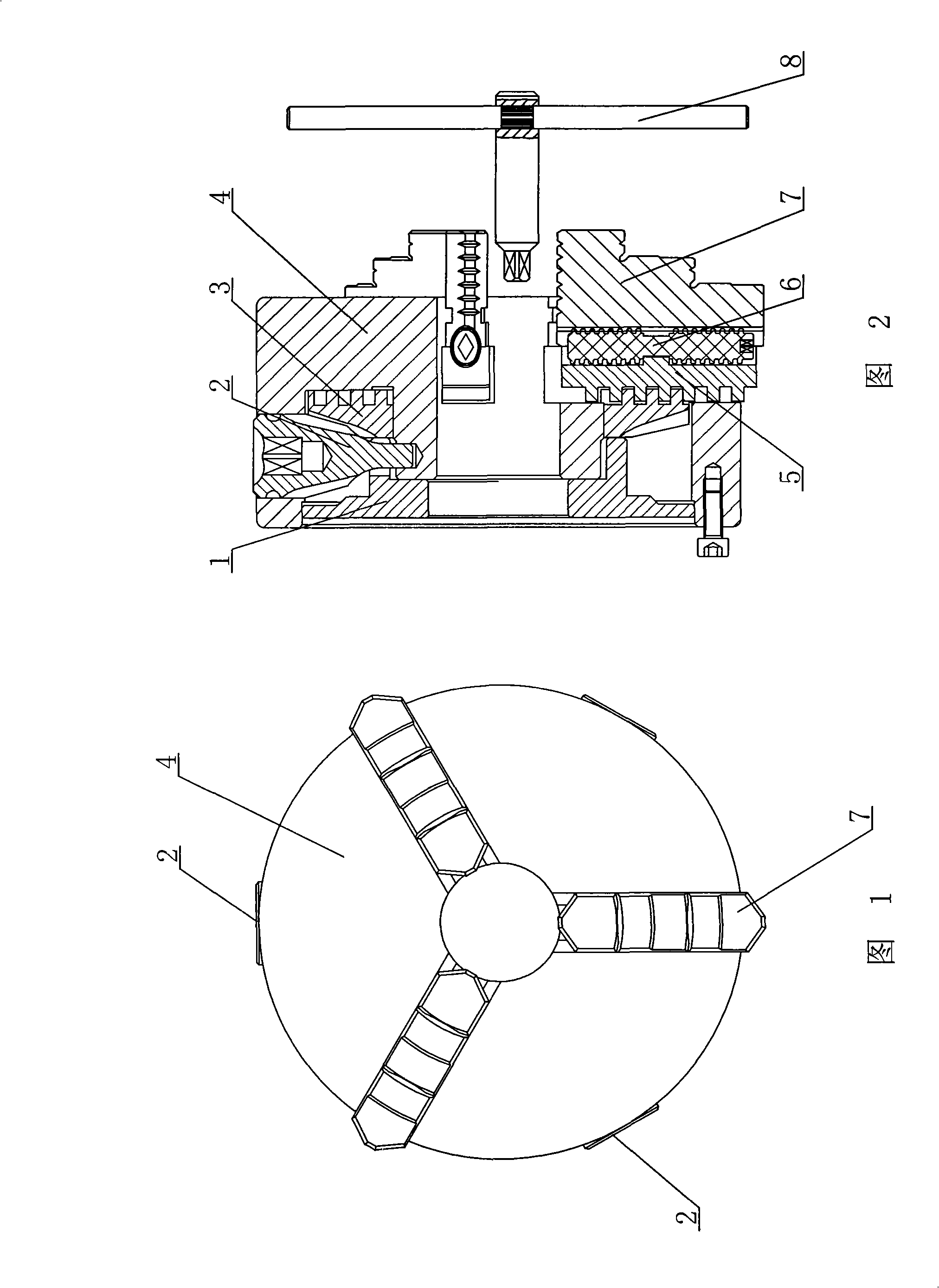

[0008] See Fig. 1, Fig. 2, the present invention comprises disk body 4, three claws, disk wire 3, disk wire 3 is installed in disk body 4, and three claws are respectively installed in the chute of disk body 4 and are connected with disk respectively. The wire 3 meshes, and the coil wire 3 meshes with the bevel gear 2 embedded in the disc body 4. The three jaws respectively include the base jaw 5, and the base jaw 5 is respectively equipped with a screw rod 6, and the top jaw 7 is installed on the base jaw 5 respectively. The chute is engaged with the screw mandrel 6, and 1 is the gland.

[0009] The working process of the present invention is described below in conjunction with the accompanying drawings: the wrench 8 is inserted into the square hole at the end of the bevel gear 2 and rotated to drive the coil wire 3 to rotate. Claw linkage, synchronous advance and retreat, self-centering to clamp or release the workpiece. When the jaws are single-action adjustment: Insert th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com