Special hydraulic machine for horizontal fan pressure shaft

A technology for hydraulic presses and fans, applied in the field of hydraulic presses, can solve the problems of misalignment, easy wear of fan shafts, low efficiency, etc., and achieve the effect of accurate force direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

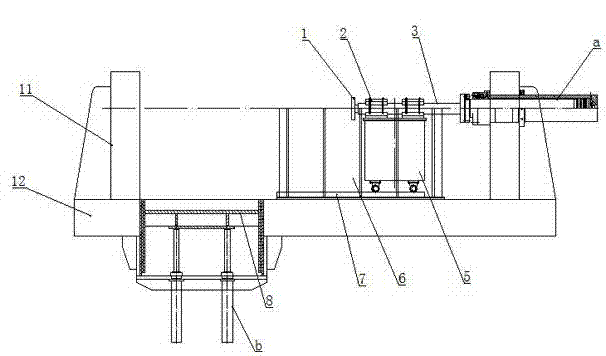

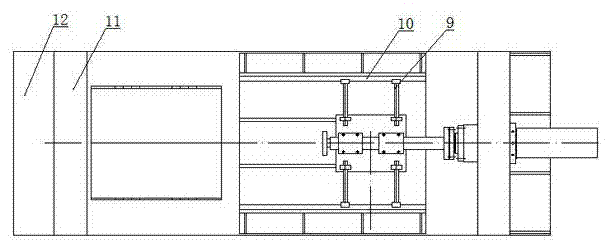

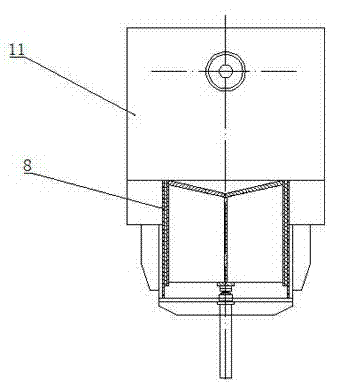

[0018] Such as figure 1 , 2 , 3, including pressing plate 1, mounting plate 2, horizontal length adjustment mechanism 3, supporting trolley 5, lateral support 6, trolley guide rail 7, fan bracket 8, adjusting screw 9, lateral limit slide rail 10, Support 11, base 12, hydraulic cylinder a, vertical hydraulic cylinder b.

[0019] The above-mentioned base 12 and the supports 11 on both sides constitute a horizontal frame, and a pressing drive mechanism that can move in the horizontal direction is installed on the support 11 on one side. In this embodiment, the pressing drive mechanism is a hydraulic cylinder a. The front end of the driving mechanism is connected with the pressing plate 1 .

[0020] A horizontal length adjustment mechanism 3 is arranged between the pressing driving mechanism and the pressing plate 1 . In this embodiment, the horizontal length adjustment mechanism 3 includes a sleeve and a screw rod built in the sleeve. The inner wall of the sleeve is threadedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com