Lock body automatic machining device

An automatic processing and lock body technology, which is applied in metal processing equipment, metal processing, measuring/indicating equipment, etc., can solve the problems of inability to guarantee the concentricity of holes, increase the labor intensity of operators, and reduce production efficiency, etc., to achieve structural Simple, reduce labor intensity and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

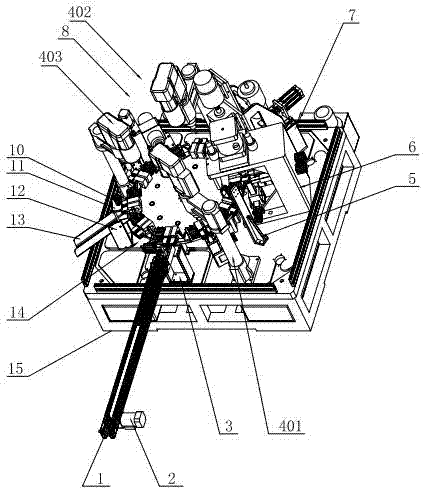

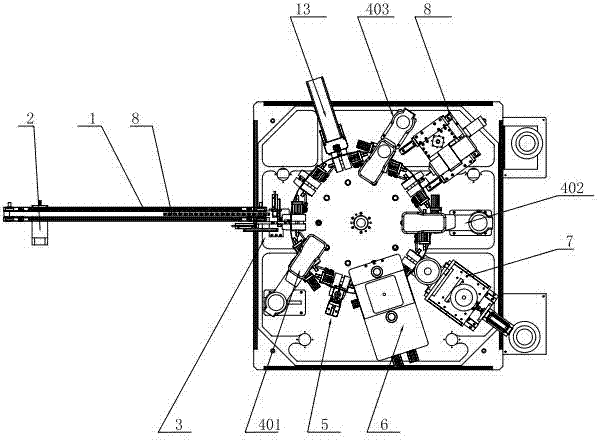

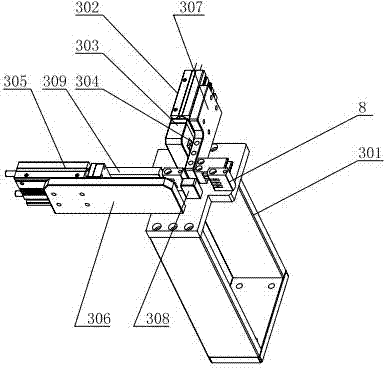

[0027] Such as figure 1 , figure 2 As shown, the present invention includes a frame 15 and a rotating disk assembly arranged on the frame 15, and multiple sets of positioning clamping units 14 are arranged along the circumferential direction of the rotating disk assembly, located on the frame 15, and positioned on the rotating disk assembly. On the outer periphery, arrange and position the feeding unit 3, the first automatic drilling unit 401, the hole position automatic detection unit 5, the automatic punching unit 6, the automatic milling unit 7, the second automatic drilling unit 402, and the small hole along the counterclockwise direction. The automatic processing unit 8, the third automatic drilling unit 403 and the discharging unit.

[0028] Such as Figure 4 As shown, the rotating disk assembly includes a total motor 16 installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com