Couple-stage axial-flow fans

A technology of axial flow fan and double-axis motor, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of poor cooling effect of the motor, pollution of the operating environment, and influence on work, so as to ensure concentricity and clean the environment Pollution, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

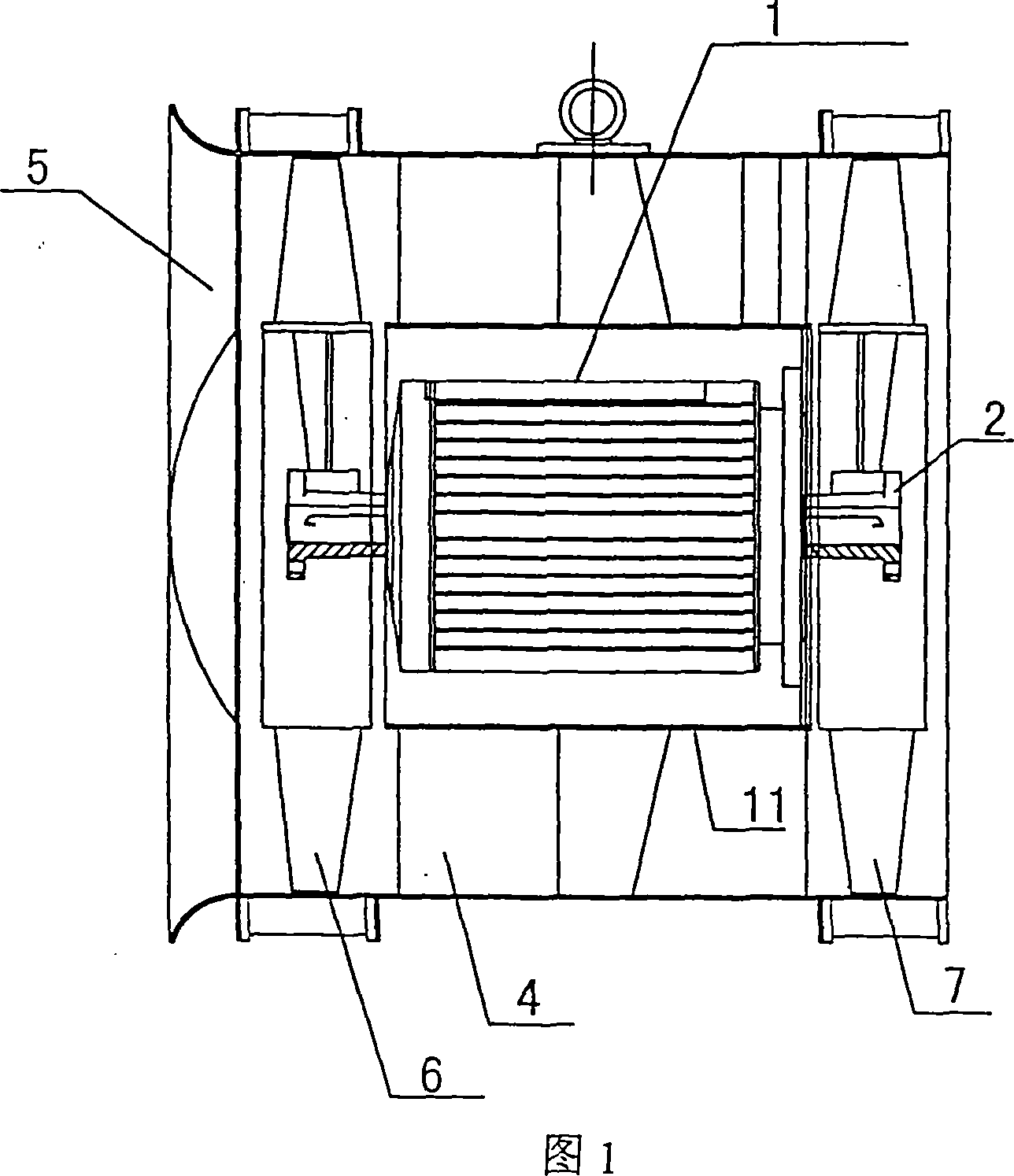

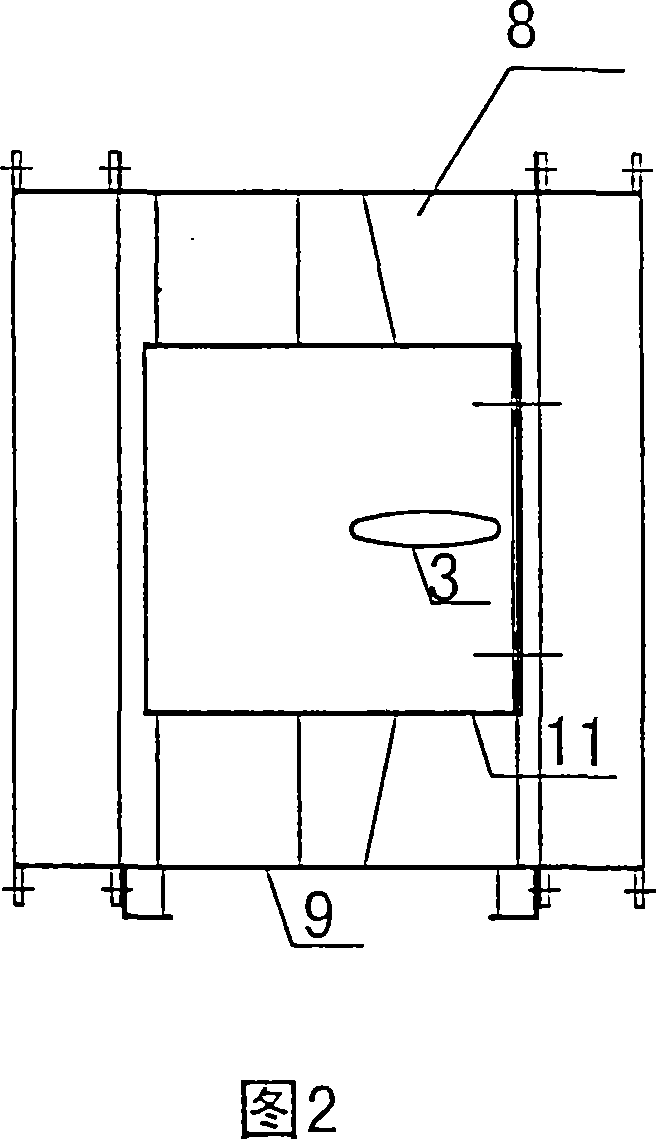

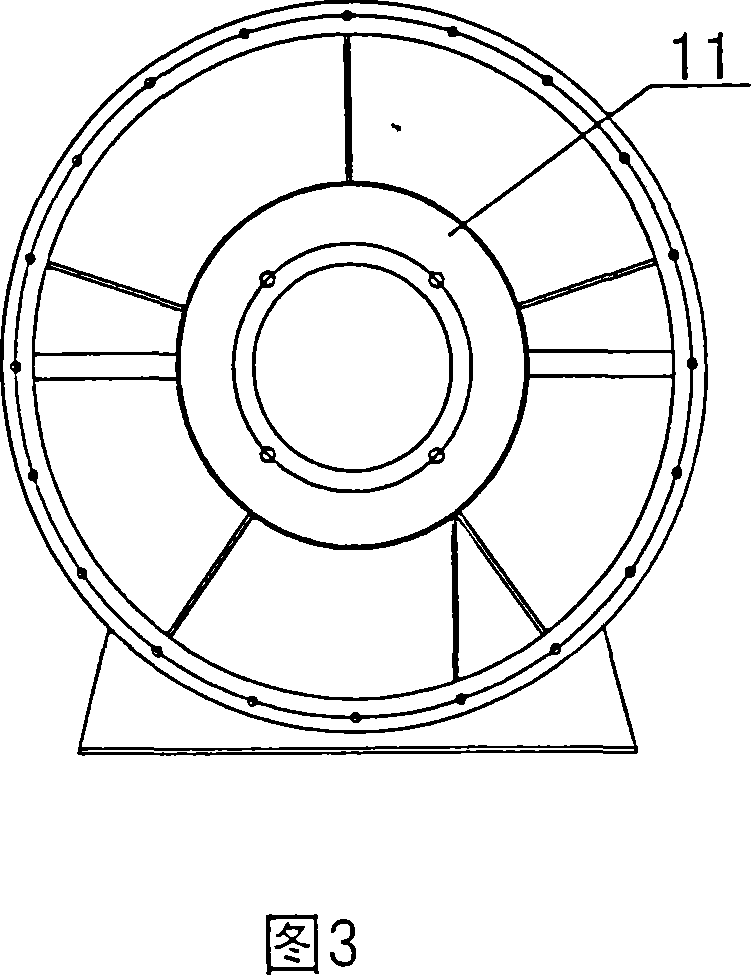

[0011] Referring to the accompanying drawings, the structure is that the shaft sleeve 2 is installed at both ends of the biaxial motor 1. The shaft sleeve 2 is tapered, and the tapered shaft sleeve has a self-locking effect, which can effectively connect the impeller and the motor shaft. Axial locking, reliable contact. The cooling pipe 3 in the cooling device is installed between the outer cylinder 9 and the middle cylinder 11. One end of the cooling pipe 3 is connected to the external environment of the motor in the middle cylinder 11, and the other end of the cooling pipe 3 is connected to the environment of the two-stage axial flow fan. The external environment of the motor refers to the airflow environment caused when the motor is cooled. The static guide vane 4 is installed behind the first-stage impeller 6, which acts as a rectifier for the first-stage impeller 6 and improves the total pressure efficiency of the whole machine. The collector 5 is installed in front of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com