Parametered assembly and design of three-dimensional mould structure and automatic dimension labeling method for two-dimensional figure

A technology of assembly design and structural parameters, applied in the direction of calculation, electrical digital data processing, special data processing applications, etc., can solve the problem of shortening the total man-hour of mold design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

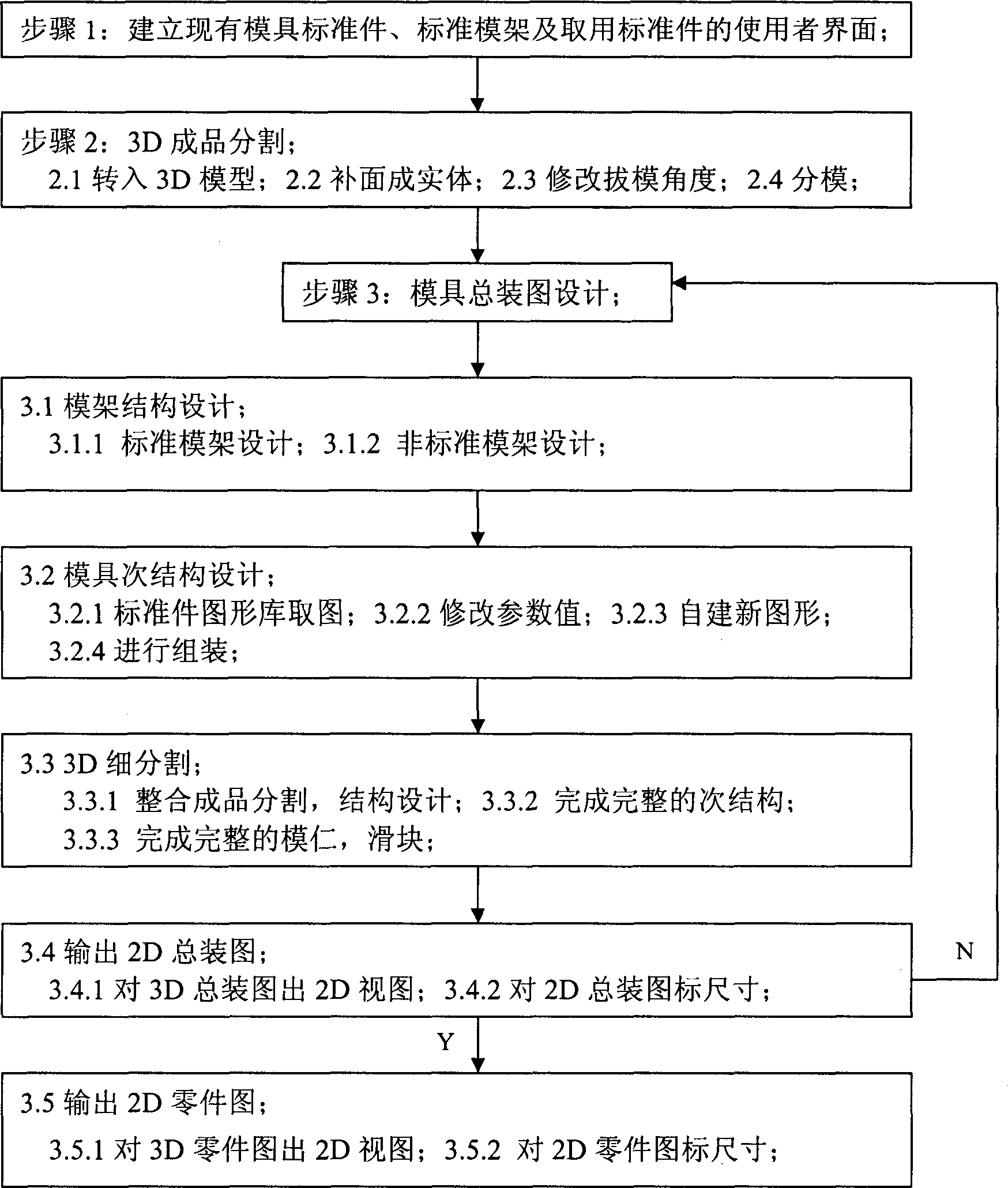

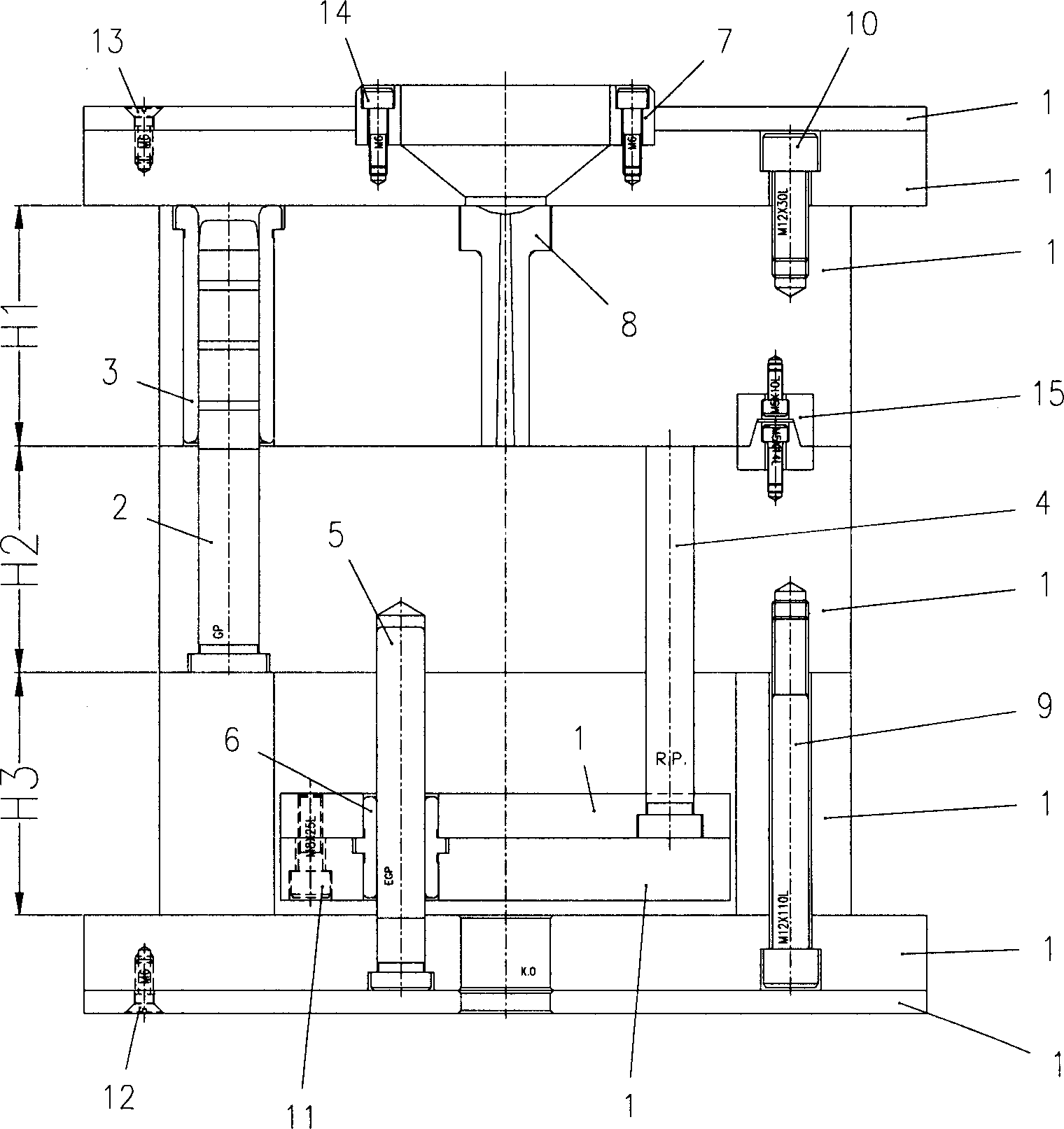

[0252] See Figure 6 As shown, the parametric assembly design of the three-dimensional mold structure and the automatic dimensioning method for the two-dimensional drawing of the present invention include the design of the mold base structure, the design of the slider structure, the design of the oblique pin structure, the design of the cooling circuit, the design of the small inlet structure, and the ejection structure. Design, output 2D general assembly drawings and 2D parts processing drawings, automatic dimensioning eight subsystems constitute the program system.

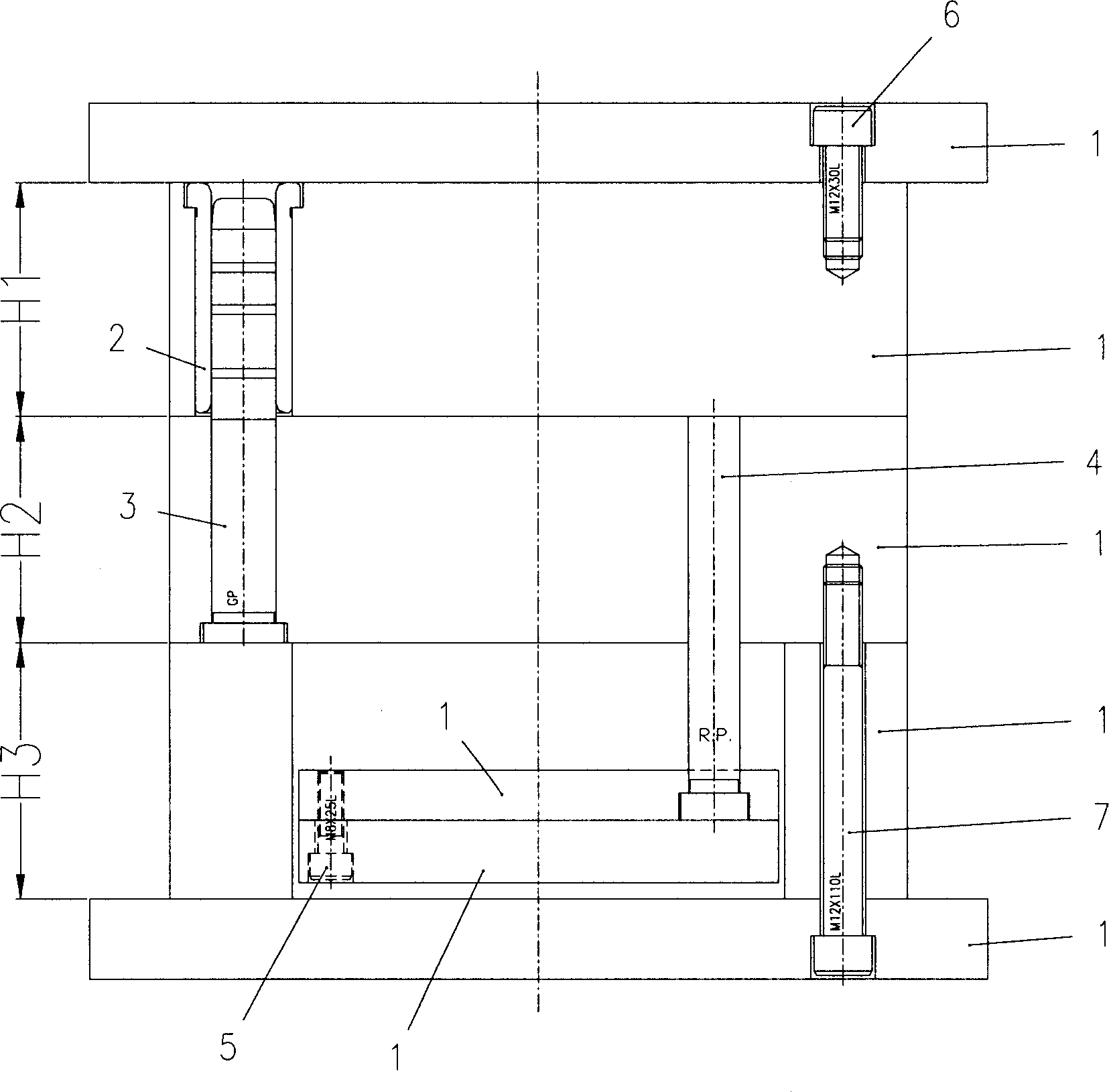

[0253] In the formwork design of the two-plate formwork of the formwork structure subsystem, a formwork diagram of the two-plate formwork with a full formwork is established first, including 13 formworks, and parameters are established to determine the position of each plate on the formwork, so that These 13 boards can be removed or added back at will. Build a multi-functional mold base standard part and non-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com