Method for designing water-spraying boost pump hydraulic model for efficient and large-power-density ship

A water jet propulsion and hydraulic model technology, which is applied in the directions of calculation, special data processing applications, instruments, etc., can solve the problems of weak design and development of the hydraulic model of the high power density marine water jet propulsion pump, and achieve high design quality and design cycle. short, the effect of increasing power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

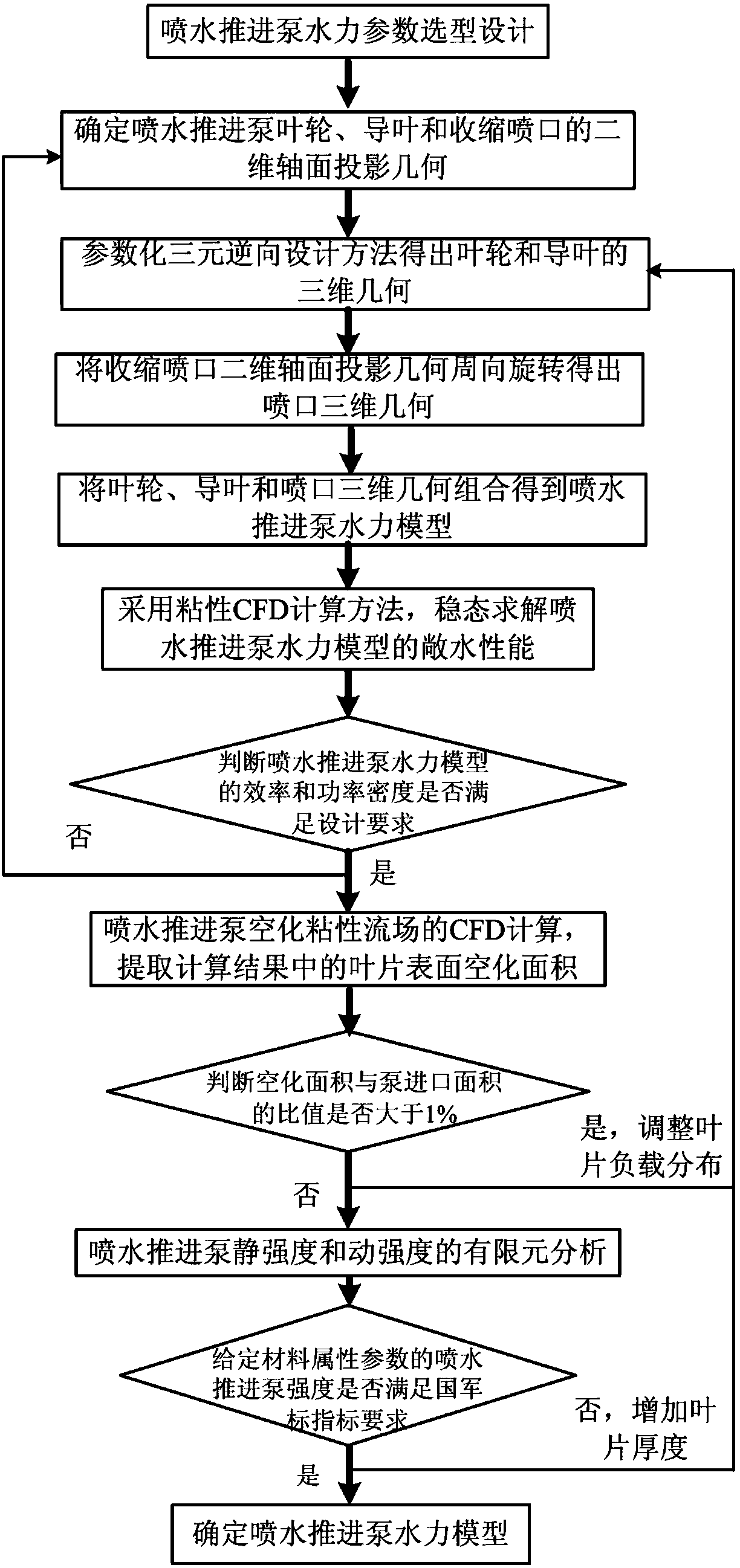

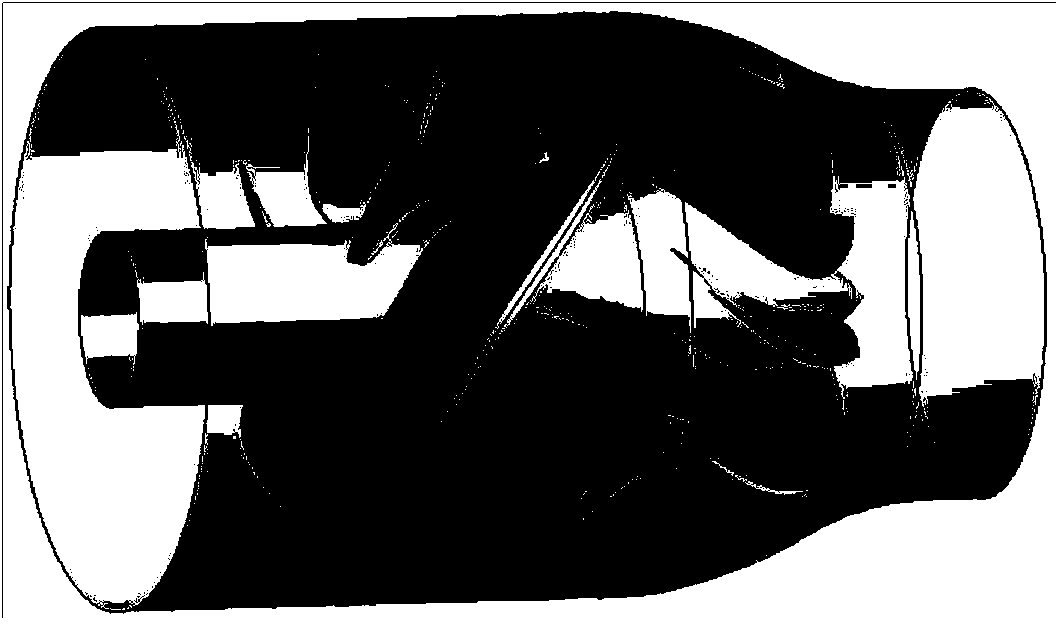

[0027] Embodiments of the present invention will now be described with reference to the drawings.

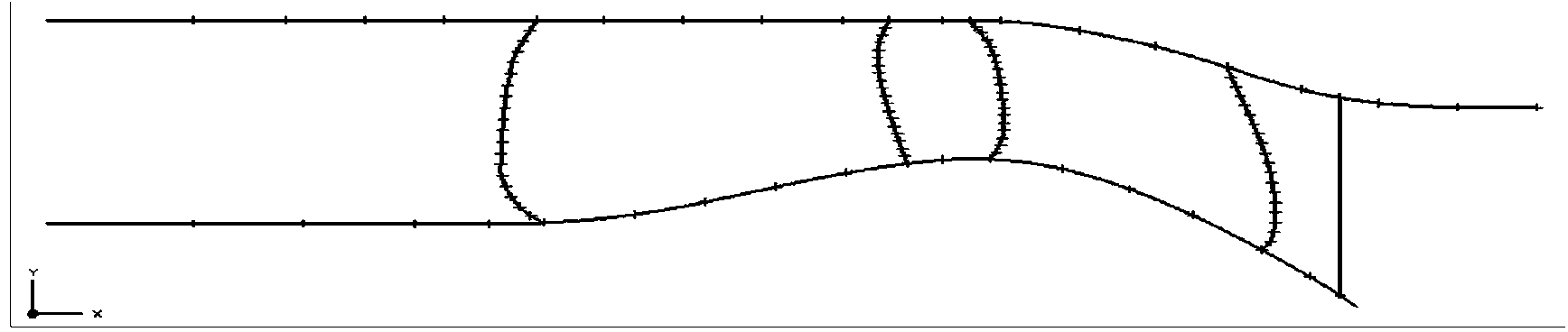

[0028] A method for designing a hydraulic model of a high-efficiency and high-power-density marine water-jet propulsion pump. The hydraulic model of the water-jet propulsion pump includes impellers, guide vanes and shrinkage nozzles. The method includes the following steps:

[0029] Step 1) Selection and design of the hydraulic parameters of the water jet propulsion pump

[0030] The five hydraulic design parameters of the water jet propulsion pump are determined according to the speed and power design indicators, the effective power can be determined by the hull resistance and the design speed, and then the rated power, rated speed and reduction ratio of the main engine can be determined according to the basic theory of water jet propulsion. Five hydraulic parameters: the head H of the water jet propulsion pump, the flow rate Q, and the nozzle diameter D j , Specific speed N ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com