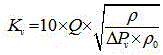

CFD simulation and grid self-adaption based valve flow coefficient calculating method

A valve flow and coefficient calculation technology, applied in the direction of calculation, electrical digital data processing, special data processing applications, etc., can solve the problems of high valve flow coefficient cost, valve size specification restrictions, and limited calculation accuracy, so as to improve the boundary layer Grid, reduce workload and difficulty, improve the effect of simulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

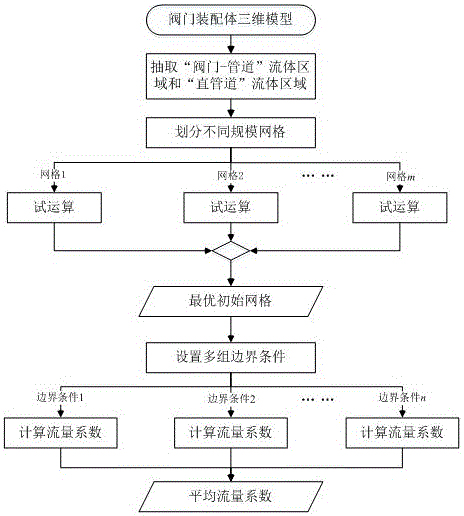

[0037] The operation steps of this embodiment are as follows:

[0038] (1) Establish flow field model and mesh division

[0039] Taking the DN500 eccentric butterfly valve as an example, use Solidworks to build an assembly model. After simplifying the small structures such as rounding, chamfering and threaded holes in this model, connect pipes with a length of 5 times the nominal diameter and 10 times the nominal diameter at the inlet and outlet. ; Then extract the "valve-pipe" flow field model with a total length of 7857 mm, and establish a "straight pipe" flow field model with a length 15 times the nominal diameter, with a total length of 7500 mm.

[0040] Using ANSYSICEMCFD pre-processing software, the "valve-pipe" flow field model is divided into mixed meshes, and the "straight pipe" flow field model is all divided into structural meshes.

[0041] (2) Judging the optimal initial grid

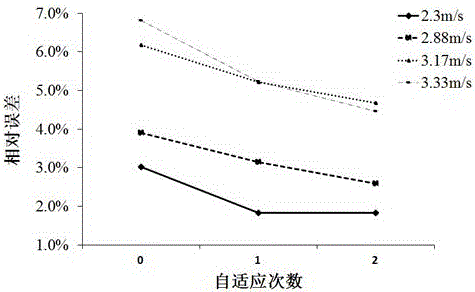

[0042] For the "valve-pipeline" flow field model, an inlet flow rate of 2.3m / s is set,...

Embodiment 2

[0063] The operation process of this embodiment is as follows:

[0064] (1) Establish flow field model and mesh division

[0065] Taking the DN100 midline butterfly valve as an example, use Solidworks to build an assembly model. After simplifying the small structures such as rounding, chamfering and threaded holes in this model, connect pipes with 5 times the nominal diameter and 10 times the nominal diameter at the inlet and outlet respectively. ; Then extract the "valve-pipe" flow field model, and establish a "straight pipe" flow field model with a length 15 times the nominal diameter.

[0066] Using ANSYSICEMCFD pre-processing software, the "valve-pipe" flow field model is divided into mixed meshes, and the "straight pipe" flow field model is all divided into structural meshes.

[0067] (2) Determine the optimal initial grid

[0068] For the "valve-pipe" flow field model, this study carried out simulation calculations at an inlet flow rate of 31.8kg / s, with four initial g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com