Construction method for manufacturing multi-pipe intersecting steel pipe component

A technology of multi-pipe intersecting steel pipes and construction methods, which is applied in the direction of manufacturing tools, workpiece edge parts, metal processing equipment, etc., to achieve the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] This multi-pipe intersecting steel pipe component manufacturing method of the present invention is used for the first 240m double-barrel self-supporting all-steel structure chimney in China, which is the first in China and Asia. The specific implementation method is as follows:

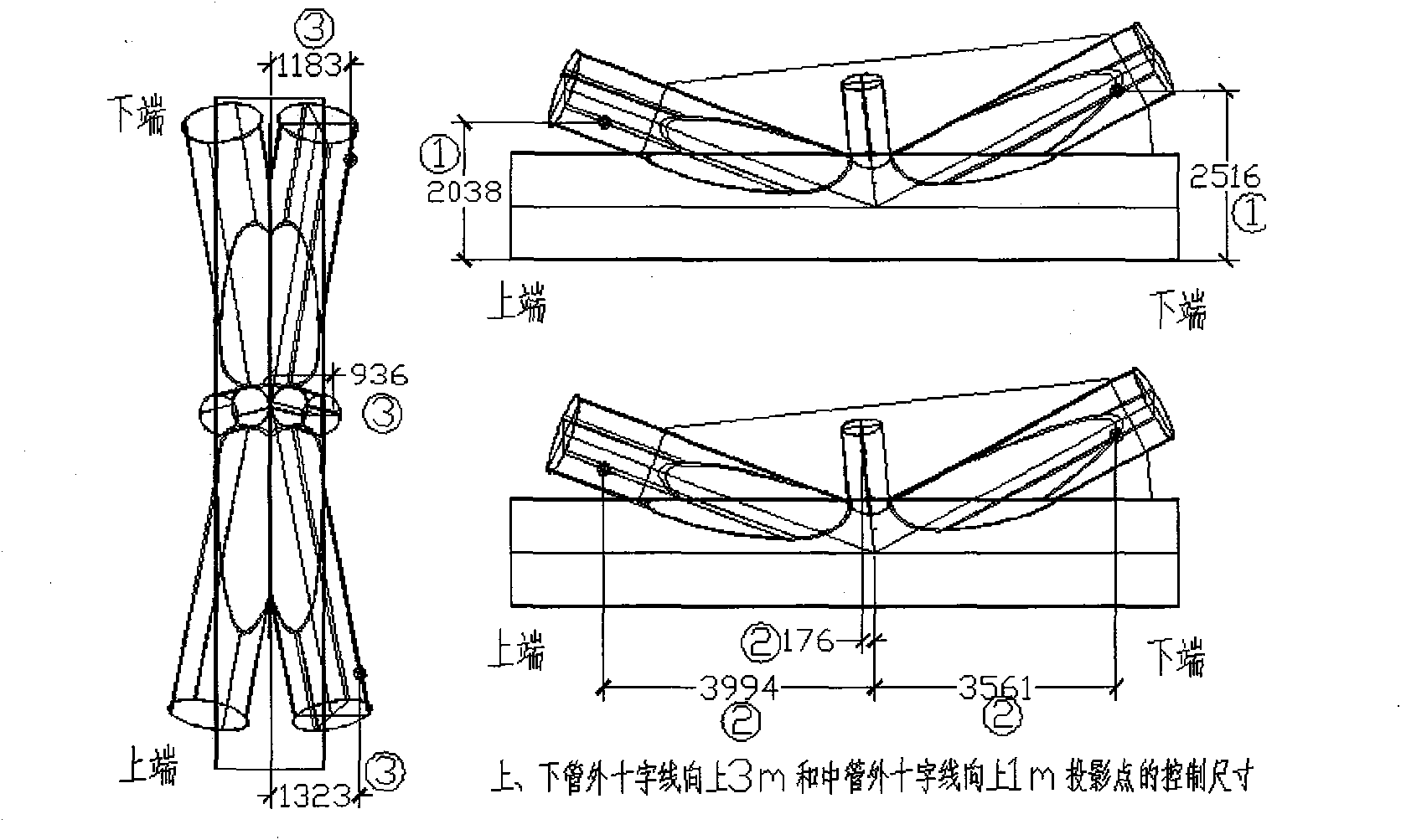

[0017] 1. Use 3D AutoCAD to model the Jinling steel chimney, divide the element line along the circumference of the branch pipe, and then draw it into a 2D diagram, see the attached figure 1 .

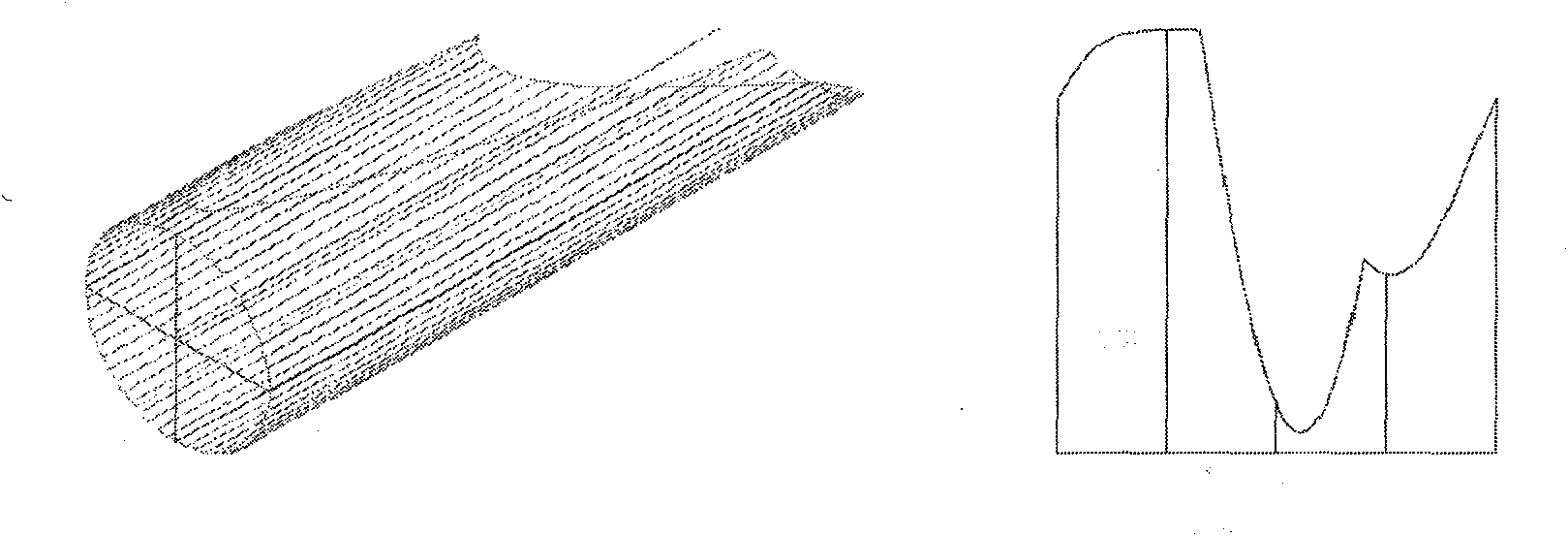

[0018] 2. After the intersecting line is drawn, print out the sample diagram according to 1:1 and cut it along the intersecting line. Attach the sample diagram to the outer wall of the steel pipe. Note that the cross lines printed on the sample diagram coincide with the cross lines on the steel pipe. The cutting line draws the cutting line on the steel pipe, and uses the flame to cut the steel pipe along the cutting line.

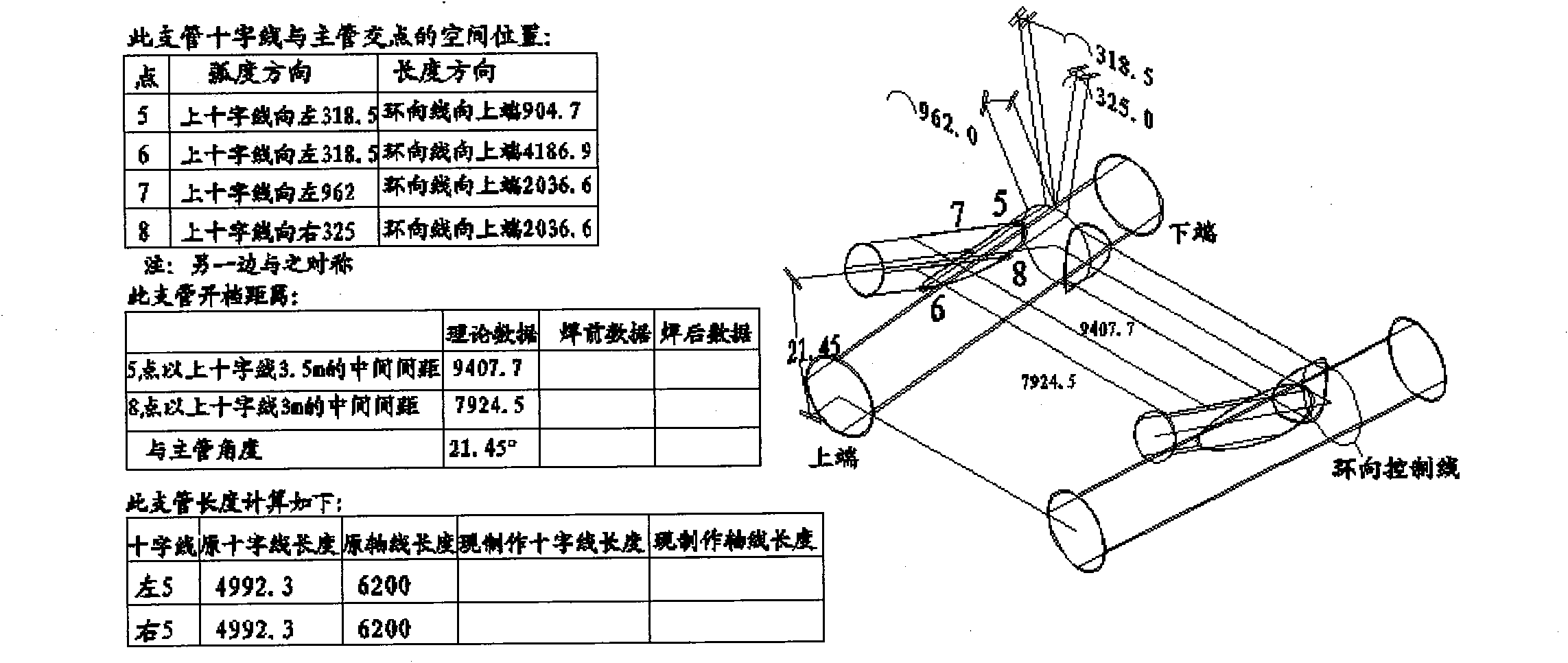

[0019] 3. Use computer modeling to find out the relative spatial relationship b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com