Three-dimensional reinforcing steel bar lofting method

A steel bar and three-dimensional technology, applied in the field of computer-aided design, can solve the problems of increased construction difficulty, heavy workload, and inability to form an accurate bill of materials, etc., and achieve the effects of shortening the deepening time, saving engineering costs, and achieving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

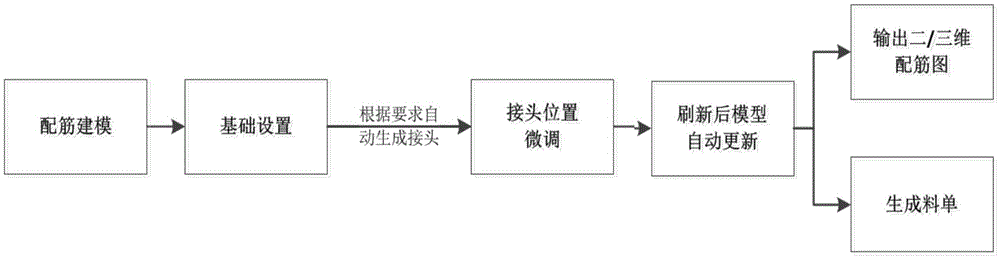

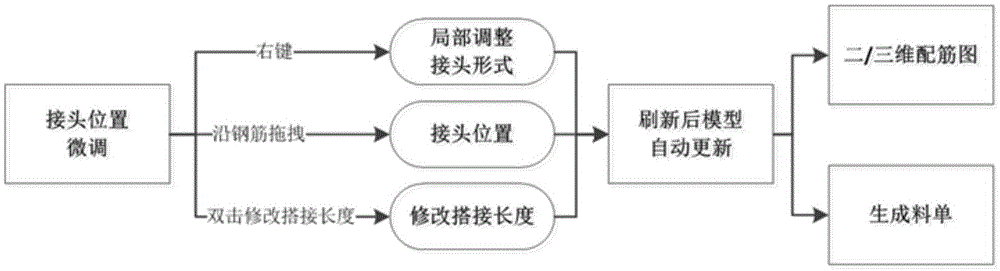

[0022] Such as figure 1 As shown, a 3D rebar flip method based on BIM technology, the specific implementation steps are as follows:

[0023] (1). For special-shaped components, the solid model of concrete components built by conventional 3D modeling software (CATIA, REVIT, 3DMAX, etc.) can be imported, and then the design reinforcement modeling is carried out; for standard components, concrete components can be automatically generated according to the design parameters Solid models, including design reinforcement models. The thickness, size, and specifications of the protective layer of steel bars are all parameterized settings, which can be dynamically updated according to design requirements.

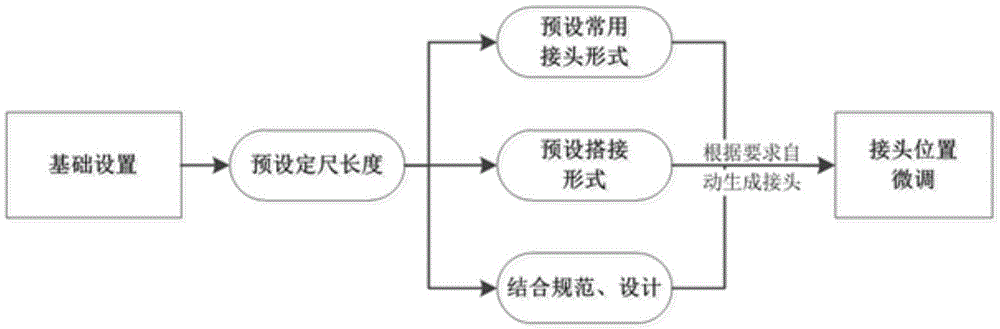

[0024] (2). According to the national building standard design atlas and the component details provided by the design unit and the overlapping form of the steel bars, and combined with the fixed length of the steel bars (6, 9, 12 meters), set the steel bar joint form and the lap join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com