Pavement construction lofting method for high-speed loop in skid pad

A high-speed ring and proving ground technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of difficult precision control, complicated lofting process, and complicated construction process, so as to avoid errors and optical centering errors, simplify the process, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In this embodiment, the stakeout method for the construction of the high-speed ring road surface of the test track is carried out according to the following process:

[0023] 1. Establish a basic control network

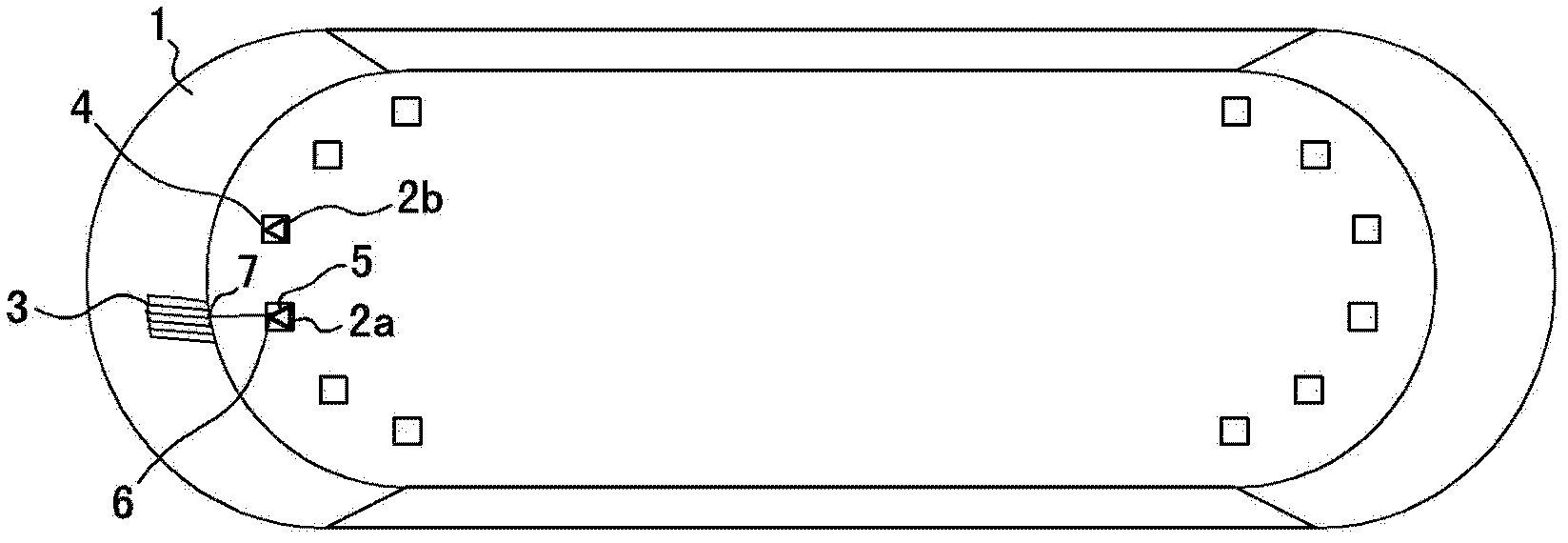

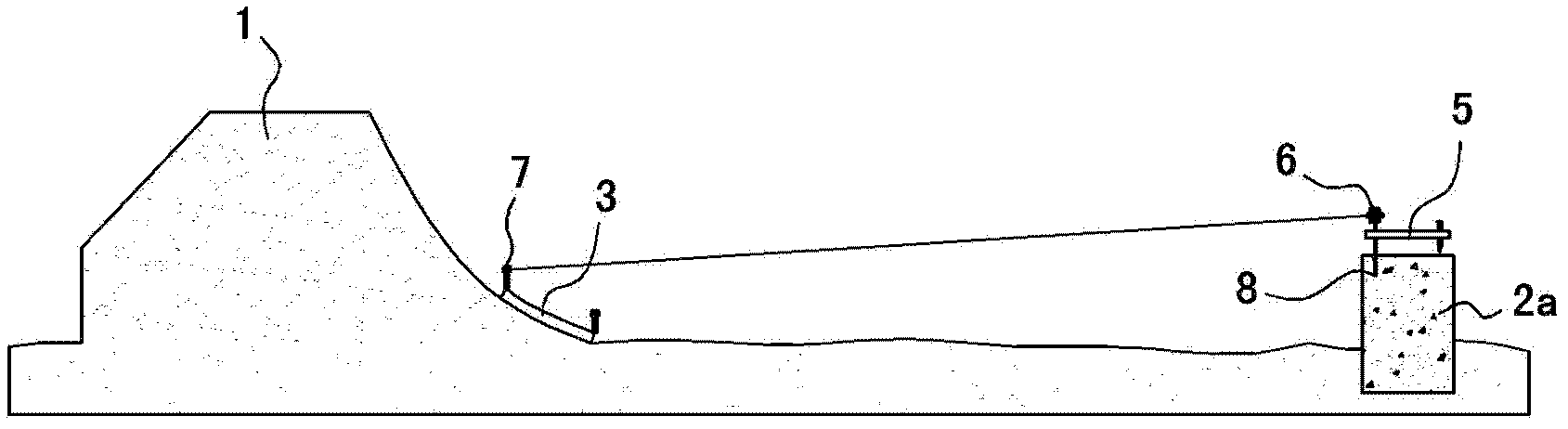

[0024] a. Set up various basic control outlets

[0025] Each basic control network point is set in the inner direction of the ring road 30-50m away from the inner edge of the subgrade 1 of the curved section of the ring road, and the distance between adjacent basic control points is 190-210m.

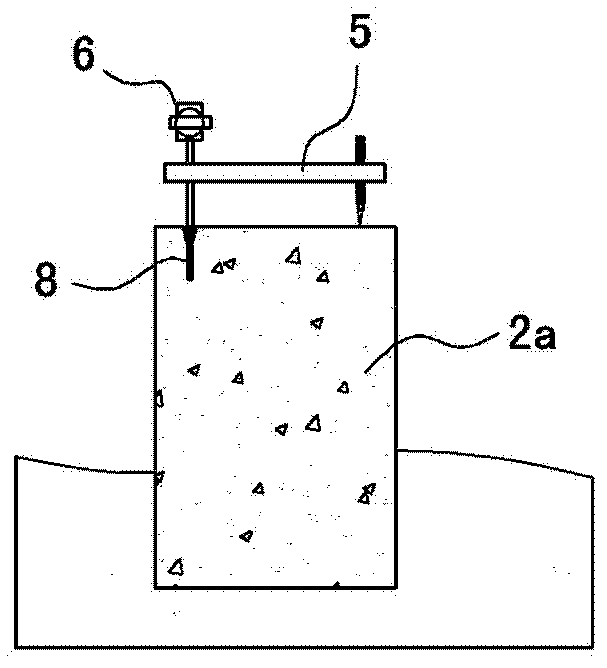

[0026] b. Buried the observation piers of each foundation control point

[0027] The observation pier of each foundation control point is set as a concrete pier column, the cross section of the pier column is 0.6m×0.6m, and the clear height of the pier column is 0.7m~1m; Due to the unstable foundation of the control network observation pier, the overall settlement of the observation pier occurs. First, the floating soil on the surface should be removed, and then the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com