Construction method and pouring device for framework masonry infill wall structure

A construction method and technology of structural columns, which are applied to building construction, formwork/formwork/work frames, and on-site preparation of building components, which can solve the problems of long construction period, poor construction quality of structural columns, and waste of labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

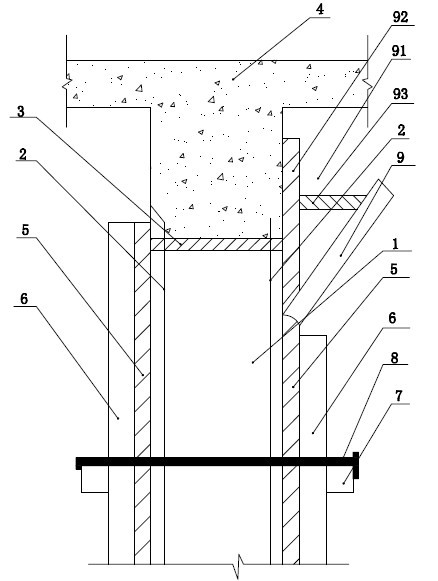

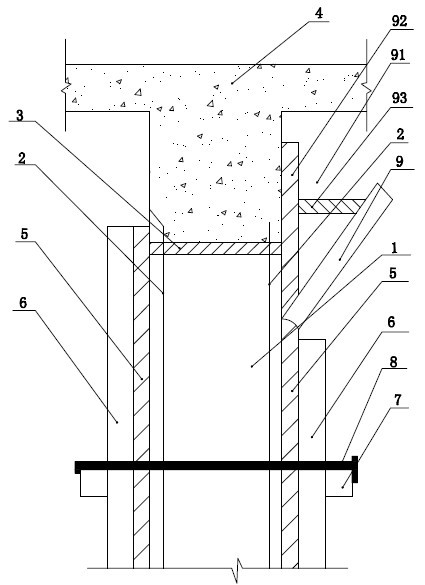

[0015] See attached figure 1 , attached figure 2 , the construction method of the frame masonry filled wall construction column disclosed by the present invention comprises the following steps:

[0016] 1. Construction stakeout: use the control point to release the axis of the wall of each layer of the building through the laser plumb or line plumb, and pop up the structure on the axis according to the requirements of the construction drawings and construction specifications The position of the column.

[0017] 2. Rebar planting at the end: In order to ensure that the position of the steel bar 2 is accurate, the longitudinal bar of the structural column 1 is pre-embedded by the post-planting bar method at the end, and the drilling depth is > 60mm. Fill with structural glue or epoxy resin solution, and then implant steel bar 2. The reserved lap length of steel bar 2 should be >500mm, and the longitudinal steel bar 2 should not be less than 4Φ12.

[0018] 3. Laying and pasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com